STRUCTeam upgrades CompoSIDE composites design engineering modules

The integrated web-based application now features an inclusive Yacht Designer license with the latest ISO 12215-5:2019 guidelines for more comprehensive marine application design.

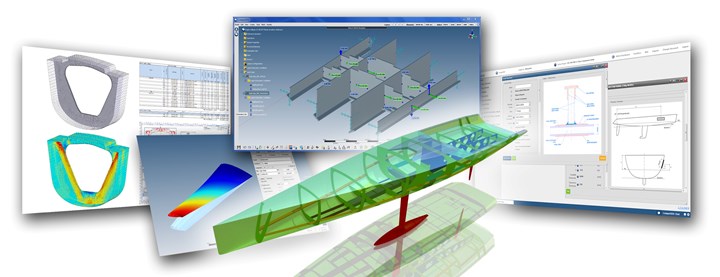

STRUCTeam Ltd. (Cowes, U.K.) has released a performance-orientated upgrade to CompoSIDE, the company’s integrated suite of web-based design engineering modules for composite marine applications. The new updates to the software have been developed to support naval architects, marine engineers and design teams that are defining hull construction and scantlings for vessels under 24 m.

The Yacht Designer subscription is fully inclusive of the revised ISO 12215-5:2019 standard and is said to provide seamless interaction between modules, including YACHTScant and FESpace. This enables users to combine design optimization and ISO compliance with monohull small craft — hull construction and scantlings.

“CompoSIDE has become an essential tool for many of our customers in the design and production of composite parts, products and the specification of structural elements,” says Julien Sellier, managing director of CompoSIDE and STRUCTeam. “This new offering is the perfect addition to a comprehensive suite of engineering modules.”

Additional key features include a default materials library, ply-by-ply laminate modeling and analysis (CLT), FEA for panels and beams; composite beams and section modeling and a bill of materials.

A live CompoSIDE demonstration will be hosted on July 6th at 1 p.m. GMT (9:00 a.m. EST) via a free-to-attend webinar. To register, email sales@composide.com.

Related Content

-

MerConcept, Extracthive integrate rCF components into racing yacht construction

Development and integration of recycled composite ballast dorade vents for an IMOCA class yacht and other ongoing projects demonstrate a push for greater circularity in the marine industry.

-

REGENT progresses seaglider prototype development, prepares for crewed testing

All-electric composites-intensive maritime craft will enhance coastal transportation capabilities by mid-decade.

-

Alliance for European Flax-Linen and Hemp reports increasing flax fiber adoption in marine

The natural fiber is increasing traction across several marine applications, including in projects by Greenboats, Northern Light Composites, the Beneteau Group and others.

.jpg;maxWidth=300;quality=90)