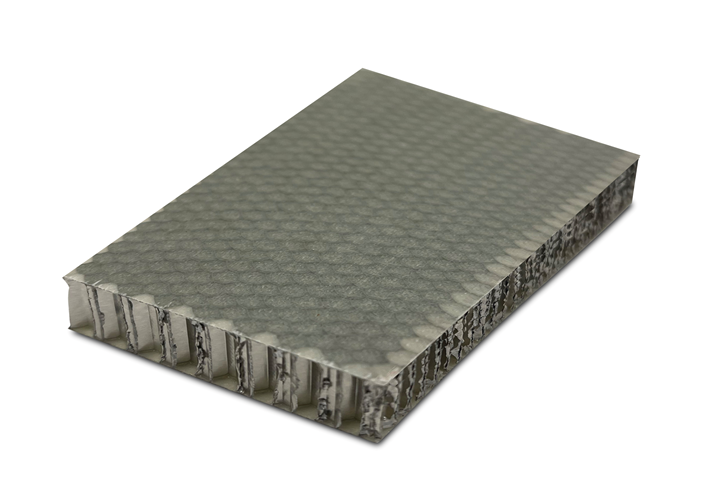

The Gill Corp. announces new Gillfab 4037 sandwich panel

Fiberglass-reinforced epoxy panel with aluminum honeycomb core meets corrosion and flame resistance specifications for use in nonstructural aircraft interiors.

The Gill Corp. (El Monte, Calif., U.S.) presents the Gillfab 4037 sandwich panel which is made of 7581 fiberglass cloth reinforced epoxy laminate facings and Dura-Core II aluminum honeycomb core. This panel is designed for nonstructural interiors in business aircraft.

Constructed with lightweight and high-strength materials, Gillfab 4037 exhibits good corrosion resistance. It also has good self-extinguishing characteristics, meeting the specification of the FAR Part 25.853 60-second vertical flammability test to ensure the safety of passengers and crew members.

On average, the panels comes in sizes of 2,438 × 1,219 mm and up to a maximum of 3,568 × 1,727 mm. Additional specifications regarding thicknesses and performance properties can be viewed here.

The Gill Corp. is a manufacturer of high-performance composite materials and products for aerospace, transportation and other industries. The company has extensive vertically integrated capabilities that include fabrication, assembly and kitting. Parts can be delivered that are ready for installation.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;maxWidth=300;quality=90)