The Gill Corp. presents FAA-approved allowables data for Gillfab 4122S sandwich panels

Composite sandwich panels meet requirements for use in aircraft interior applications such as galleys, lavatories, partition walls, bulkheads, sidewalls and ceilings.

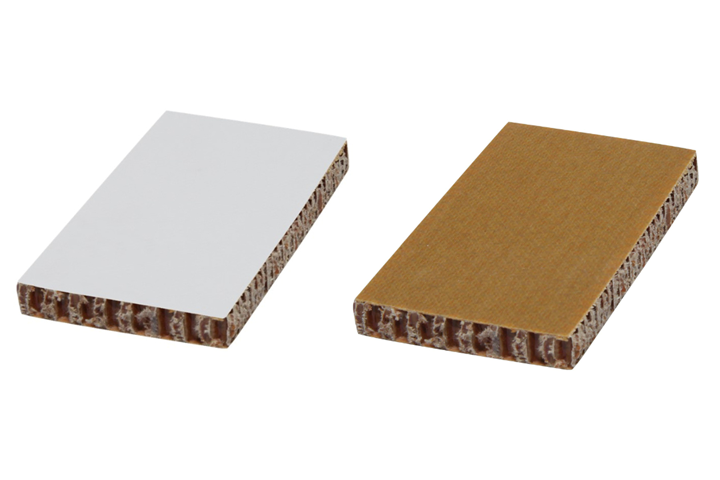

Gillfab 4122S sandwich panels with Tedlar (left) and without Tedlar (right). Photo Credit: The Gill Corp.

The Gill Corp. (TGC, El Monte, Calif., U.S.) has announced that the company’s Gillfab 4122S sandwich panel is now available with allowables data that has been approved by the Federal Aviation Administration (FAA). OEMs and MROs can use this product with confidence as they design and manufacture interior structures and monuments, TGC says.

“This project was a collaborative effort between TGC and Structural Integrity Engineering (SIE, Los Angeles), after Gillfab 4122S was selected for use in the forward galley, lavatory and ceilings of their new narrow body freighter conversion program,” Candi Burdick, TGC director of aftermarket sales, says. “Our R&D team worked diligently with SIE engineers and the FAA to complete this project on an accelerated timeline. We’re thrilled with this achievement and we’re just getting started.”

Gillfab 4122S is a lightweight, low smoke and toxicity sandwich panel made from woven glass fiber-reinforced phenolic facings bonded to meta-aramid honeycomb core. One mil white polyvinyl fluoride film can be added on the face side or both sides of the panel.

This panel meets the flammability requirements of 14 CFR Part 25 App F Parts I, IV and V for use in aircraft interior applications such as galleys, lavatories, partition walls, bulkheads, sidewalls and ceilings.

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.