Virtek presents Iris ActiveTrack laser positioning software

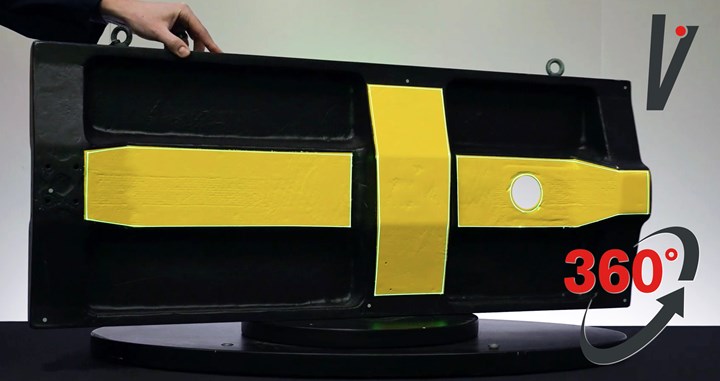

Real-time tracking software enables technicians to continuously project stable, accurate laser lines onto moving parts.

Photo Credit: Virtek Vision International Inc.

On June 1 Virtek Vision International Inc. (Waterloo, Ontario, Canada) announced the release of its Iris ActiveTrack laser positioning software that continuously projects stable, accurate laser lines onto moving parts — including complex 3D shapes — to guide workers in a variety of manufacturing processes. Virtek says the precise projections dramatically accelerate time to market and ensure product quality.

According to Sean Francoz, Virtek Group project manager, Iris ActiveTrack enables technicians to position the right part, in the right place, at the right time, even while the part is in motion. Because of this, the technology is said to eliminate time spent reviewing paperwork, measuring, marking and using templates during assembly processes, as well as eliminating rework caused by quality escapes.

Along with the launch of Iris ActiveTrack, Virtek also released the newest edition of its Iris 3D software with enhanced API (Application Programming Interface). This enhancement includes a production reporting database. Accessed through the API, the production reporting tools are said to provide instant remote access to current production status for any system on the floor. It also enables retrieval of detailed production data from any point in the systems history. This can be used to help production managers analyze performance on the macro (entire process) or micro (work cell or individual task) level.

Virtek notes that Iris 3D’s enhanced API includes a powerful toolset that allows users to employ Virtek’s Vision Positioning System (VPS) to locate a targeted tool or component anywhere in the system’s field of view and report the position of the tool relative to the projector. This functionality informs operators of the system’s status, where it is in the overall workflow and provides digital data of tasks being performed.

Kongsberg Defence & Aerospace (KDA, Norway), a long-time Virtek customer reports that Virtek’s solutions have enabled the company to surpass its cost and quality targets, with as much as a 30% cost reduction and a 25% quality improvement seen in certain applications. In particular, KDA says the use of Iris ActiveTrack technology for laser-assisted masking in its surface preparation department have experienced throughput improvements that are expected to reduce costs by 20%.

.jpg;maxWidth=300;quality=90)