WH Lipex introduces single fiber applicator for glass fiber sizing implementation

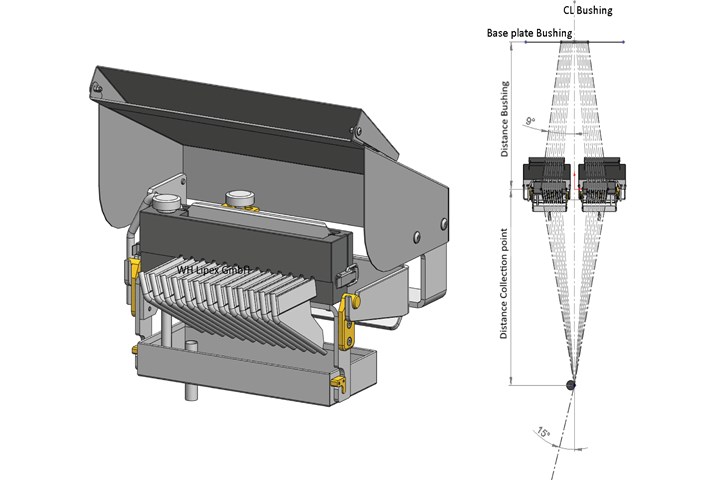

Coating module individually displays glass fibers for complete fiber wetout and improved bonding capabilities.

Photo Credit: WH Lipex

WH Lipex (Munich, Germany) part of Woollard & Henry Group (Aberdeen, U.K.) and a fiberglass technology company, introduces the single fiber applicator, a coating module that enables manufacturers to apply sizing to individual glass fiber strands.

Fibers are no longer in bundles, but are instead individually displayed, ensuring all individual filaments are better enclosed with wetting additive. This performance is said to significantly increases the sizing amount on the fibers, improving their bonding capabilities.

Further, WH Lipex says the applicator’s main advantages include increasing the end product’s mechanical properties, thus offering new possibilities for weight and cost reduction.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;maxWidth=300;quality=90)