Zünd Connect automates production monitoring, optimizes cutting system productivity

Monitoring tool compiles production data into key performance indicators (KPIs) to assess how efficiently cutting systems are working and identify areas of workflow optimization.

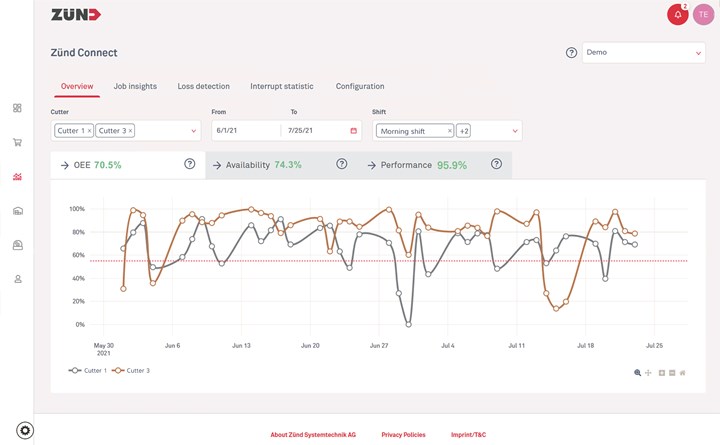

Zünd Connect is an automatic, web-based production monitoring tool from Zund America (Oak Creek, Wis., U.S.) that compiles production data from integrated Zünd cutting systems into meaningful key performance indicators (KPIs), such as cutter capacity, availability and overall equipment effectiveness (OEE). Zünd Connect helps create transparency into why machine interruptions occur, how much time is spent in setup and more to assess how efficiently cutting systems are working and to identify areas in the digital cutting workflow where optimization is possible.

Moreover, the tool gives users access to a comprehensive overview of cutter performance data at a glance, any time of day. The system records productivity levels over a freely definable period using Zünd Cut Center – ZCC (Version 3.4 or later) as data source. Zünd Connect consists of multiple dashboards with specific options for evaluating data:

Overview: This dashboard provides past production data and indicates, for example, fluctuations in machine utilization. The user can select various views and switch between indices for OEE, availability and capacity. In addition, a filter function can be used to compare performance across different shifts.

Job list: This shows a list of processed jobs, what they entailed, the time it took to produce them and the cutting distance traveled per job. Diagrams show the time spent by each individual material/substrate, processing method, tool and module. In reference to materials, for example, bar graphs show the processing time for each material used during a specified time frame.

Loss detection: This view visualizes losses in terms of time. It shows, for example, when process interruptions tend to occur most often. Loss detection enables the user to evaluate factors such as the specific time frames, materials or tools most likely to be associated with interruptions.

Interruption statistics: This lists the reasons for such interruptions. The user can filter for time of day, material, method, tool or module. The statistical representation shows the user how many hours the cutters were unable to produce during a specified period because of machine interruptions.

Zünd Connect is available in a “Monitor” or an “Analyzer” version. The former consists of a graphical display of OEE and is available to all ZCC users for free. The “Analyzer” version is said to make it possible to perform subsequent analysis and pinpoint productivity losses. It also provides the necessary tools for the user to be able to evaluate the production process and recommend improvements.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.