Search Results

Showing 21 – 30 of 99 results

Backed by recently acquired Filton Systems’ digital engineering and aerospace capabilities and composite tanks testing, and NTS Laboratories’ H2 facility, Element adds new equipment, expands team for H2 advancement.

COAST is capable of precise measurement and defect detection on contoured composite surfaces during the AFP process, reducing costs and increasing AFP accessibility.

For 42 months, the Aitiip Technology Center will coordinate the EU-funded project to design a new range of intermediate materials, such as pellets or resin-impregnated carbon fibers, which will be used to manufacture more sustainable final products.

The JEC Group has announced the winner for each of the 11 Innovation Award categories. Learn more about the winners and their projects at JEC World 2024.

Large-format AM specialist Caracol and partners designed custom, 3D-printed outdoor furniture with glass fiber-reinforced recycled polypropylene, and conducted an LCA to evaluate and improve the process.

Simultaneous certification for bio-based and circular raw materials continues Teijin’s commitment to the circular economy. Commercial production to begin in first half of 2024.

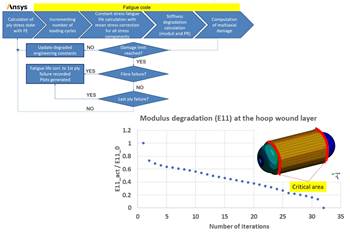

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Calculations from SKZ confirm that polyphenylene sulfide (PPS) made with this proprietary recycling process reduces the carbon footprint by 45%.

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

U.K. consortium aims is to develop a material from recycled glass fiber with mechanical properties superior to virgin glass but at a price point lower than carbon fiber.