ATL/AFP

Carbon fiber cryotank angles for a place in launch systems

Boeing has manufactured two carbon fiber cryotanks that are being evaluated by NASA for use in heavy-lift launch systems. They offer 30 weight and 25 percent costs savings.

Read MoreHighlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

Read MoreBuilding a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

Read MoreComposites slake the world's thirst

As the global thirst for drinkable water increases, the composites industry is drinking in the tremendous possibilities in seawater desalination.

Read MoreComposites automation: Trending smaller and robotic

Although AFP and automated tape laying (ATL) lamination technologies are widely used in the aircraft industry, market conditions in the past few years are driving some changes in composites equipment supplier product lines. Consultant Carroll Grant explains why.

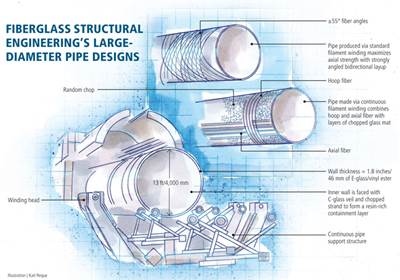

Read MoreDesigning for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

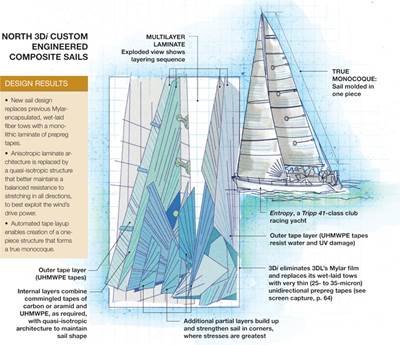

Read MoreCustom-engineered composite performance yacht sails

North Sails introduces 3Di materials and process for structural composite sails.

Read MoreThe Plane in Spain

Site tours provide a rare glimpse into the Iberian Peninsula’s aerospace composites sector, with a special focus on Airbus’ activities at Illescas.

Read MoreA350 XWB update: Smart manufacturing

Spirit AeroSystems actualizes Airbus’ intelligent design for the A350’s center fuselage and front wing spar in Kinston, N.C.

Read More