BMI

Thermoplastics in Aerospace Composites Outlook, 2014-2023

Capable of volume production, thermoplastic composites will gain new market share in the aerospace industry.

Read MoreFarnborough 2014 Airshow Report

No longer a novelty at aerospace trade events, composites nevertheless faced competition from conventional materials at this year’s event.

Read MoreJEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

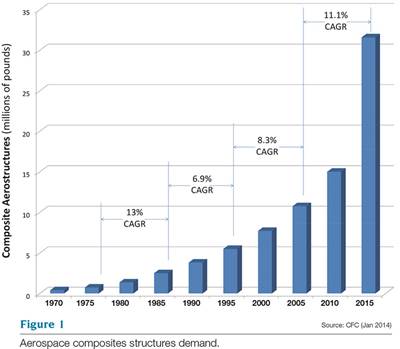

Read MoreThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

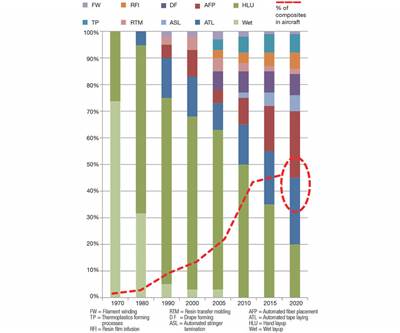

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

Read MoreRenegade Materials demonstrates OOA BMI in wing spar

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications.

Read MoreBMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreBenzoxazine: An alternative to phenolic for interior fire safety?

As research into benzoxazine resin chemistry proceeds, this budding high-performance system has the potential to challenge phenolic resins in aircraft interiors.

Read MoreBenzoxazine + BMI?

Resin supplier Huntsman Advanced Materials (Basel, Switzerland and The Woodlands, Texas) sees benzoxazine resins as traditional chemistry boundary breakers that open whole new resin-system possibilities.

Read MoreTooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

Read More