Renegade Materials demonstrates OOA BMI in wing spar

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications.

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications. Its six-hour vacuum bag/oven cure at 375˚F/191˚C with freestanding six-hour postcure at 475˚F/246˚C reportedly results in parts with low void content — a mere 0.5 percent — in sections as thick as 0.25 inch/6.35 mm. The cured material’s hot-wet mechanical properties and damage tolerance are said to be equivalent to autoclave-cured materials.

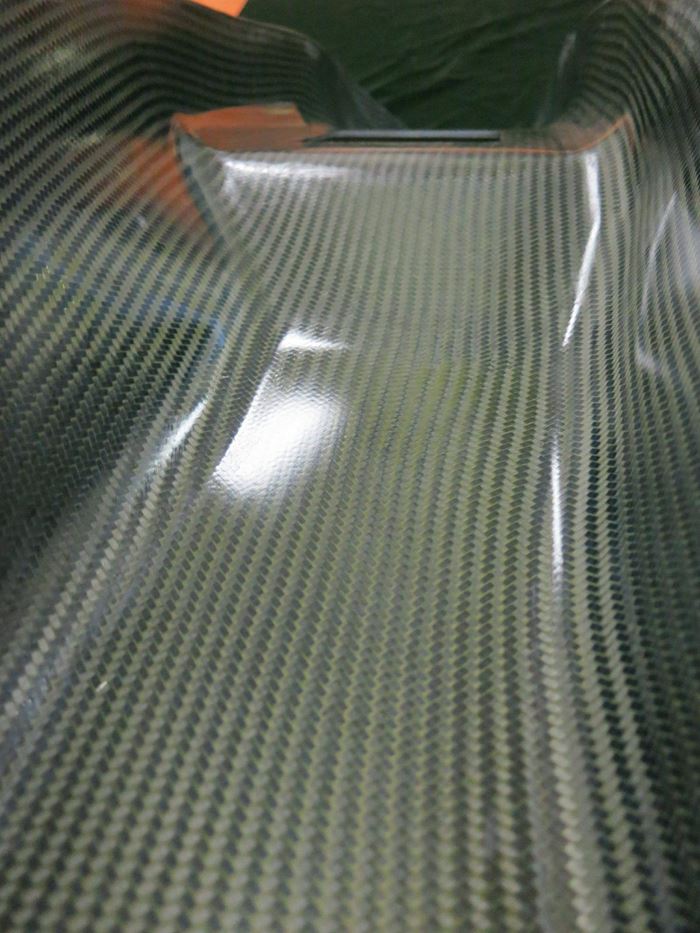

RM-3004 reportedly can be used to produce structures with service temperatures as high as 400°F/204°C. Its excellent surface finish can be seen in the accompanying photos of an aircraft wing spar demonstrator. The spar required a prepreg with excellent tack and drape characteristics due to the part’s complex geometry, yet could maintain the part’s primary load capability.

Renegade general manager and cofounder, Laura Gray, summarizes the processing advantages RM-3004 offers to aerospace parts and tooling fabricators: “Autoclave-equivalent performance with only an oven reduces processing cost, enables use of lower cost tooling, and also extends tooling life cycles.” Gray adds that a variety of nanomaterials can be incorporated into RM-3004’s resin system to tailor laminate properties and achieve multifunctional performance.

Renegade has formulated compatible BMI paste adhesive products RM-3006 and RM-3007 for use with RM-3004 prepregs, and also offers RM-3000 BMI systems for resin transfer molding (RTM) and RM-3010 for low-pressure resin infusion/vacuum assisted RTM (VARTM) processing.

This short article is a sidebar to a feature story titled "BMI and benzoxazine battle for future OOA aerocomposites." To read the main article, click on its title under "Editor's Picks," at top right.

Related Content

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Hexcel introduces mid-temp Flex-Core HRH-302 honeycomb core

Bismaleimide (BMI) option to serve complex curvatures and thermal management needs of military, commercial and UAM aircraft.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.