Carbon Fibers

Sino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read MoreAirbag housing prototype puts 3D-printed composites to the test

A feasibility study demonstrated the cost- and time-saving potential of replacing a part’s current materials and processes with additive manufacturing.

Read MoreLilium, Toray reach carbon fiber supply agreement

Toray will provide carbon fiber directly to Lilium during development of the Lilium Jet eVTOL craft, and then to suppliers during prototyping and production. Includes video of Lilium Jet test flight.

WatchArevo launches direct-to-customer 3D-printed bicycle

The Superstrata brand features a fully unibody carbon fiber/polyamide frame manufactured using Arevo’s direct deposition additive manufacturing process.

Read MoreStrata delivers 100 shipsets of inboard flaps for Airbus A350-900

Strata assumes fabrication and assembly duties for inboard flaps production and plans to incorporate HDF and ATL machines into the process.

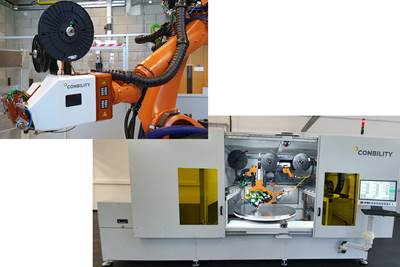

Read MoreConbility: Mass production of composite tape laminates

RWTH Aachen spin-off scales up production for low-cost, in-situ consolidated composites as inserts for lighter, cheaper injection-molded parts.

WatchEngineering Technology launches servo tensioner for filament winding

The ST2 system, tested with pitch carbon fiber and alumina fiber, enables high-speed wet, dry and towpreg winding.

Read MoreSetforge, 9T Labs collaborate to replace metal part production with composites

The substitution, enabling Setforge’s serial production of CFRP components, will be aided by 9T Lab’s Red Series technology.

Read MoreComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreDeveloping a linerless, all-composite, spherical cryotank

Infinite Composites Technologies’ Type V pressure vessel for storing cryogenic space launch vehicle propellants shows promise for eliminating elusive microcracking issues.

Read More