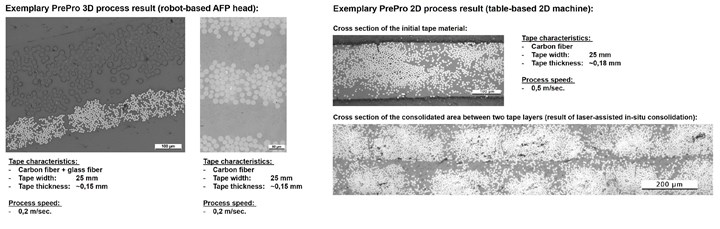

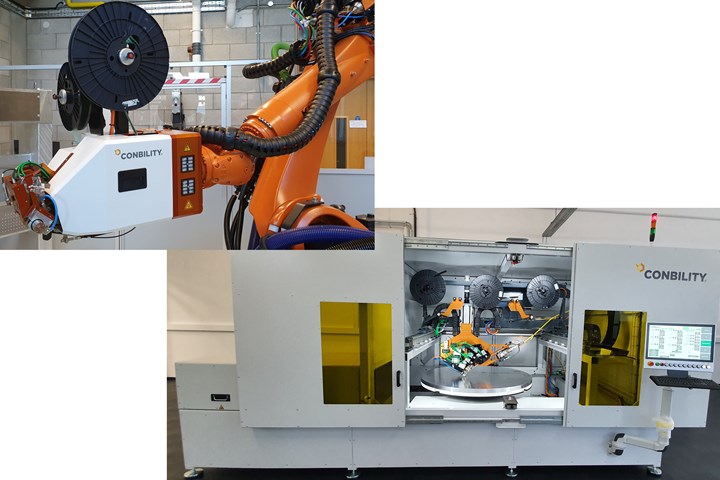

Conbility’s PrePro 3D (top) AFP head and PrePro 2D automated cell (bottom) for producing in-situ consolidated tailored composite laminates. Source | Conbility

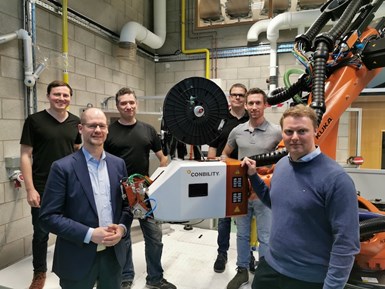

Conbility (Aachen, Germany) was established in 2015 as a spin-off from RWTH Aachen, the largest technical university in Germany. “We founded Conbility to supply unidirectional (UD) tape placement machines,” explains Dr. Michael Emonts, Conbility managing partner. Previously chief engineer for machine development at Fraunhofer IPT in Aachen, Emonts co-founded this spin-off together with fellow managing partner Dr. Kai Fischer, providing a means for commercializing Fraunhofer’s 25 years of experience in tape placement machine development. “But our first product was actually software,” he notes.

Oplysis is a simple tool for production planning that uses an intuitive drag-and-drop interface. “You can model any kind of production chain to get cost and cycle time, and can analyze capacity and bottlenecks,” says Emonts. “Normally, companies start with Excel to determine what machines they need, production rate, material consumption and waste. We developed Oplysis initially for ourselves, as an alternative to Excel to save time. As we were commercializing Conbility systems, we always had to do cost evaluations, and it was very labor-intensive.”

In 2018, Conbility was ready to move from lab-scale tape placement systems to industrial-scale machines. “We first announced a multi-material placement head capable of applying thermoset and thermoplastic tape plus dry fiber — a single investment for three different material capabilities,” says Emonts. PrePro 3D is a standalone AFP and winding head that serves as a “plug-in” for existing robot or machine systems. Conbility received its first order in June 2018 and delivered the system 3.5 months later to Technology Center AIMEN (O Porriño, Spain). “We integrated the AFP head control system into their existing robotic manufacturing cell,” he adds.

Conbility’s second PrePro 3D AFP head was delivered to University of Limerick in December 2019.

Source | Conbility

Conbility delivered its second AFP head to University of Limerick, Ireland, in December 2019. “Now we’ve sold a third AFP head to an industrial company outside of Europe to produce parts for the automotive industry,” says Emonts. “We see the opportunity to potentially place more systems there in the future.”

In-situ consolidated, composite tailored blanks

“Our latest product, the PrePro 2D, addresses the market for mass production of composite components — a 2D machine to produce tailored blanks with in-situ consolidation,” he explains. “We are using laser energy in the process zone without melting the whole tape thickness. Instead, we melt only a very thin layer so there is no degradation of the tape. The laser is also much faster than infrared heating, enabling speeds of up to 1 meter/second, and also produces a more homogeneous distribution of energy intensity. If you compare all table-based machines for producing tailored blanks, ours is the first to use a laser as well as in-situ consolidation.”

“We see a huge demand in the future for injection molded parts that need to be stiffened via tailored blanks as inserts,” says Emonts. “The heated table we use is key to minimizing temperature variation, and thus reducing thermal stress in finished parts. Although it can go up to 200°C, the table is not heated to melt temperature; normally, it is enough to hold the table at 120-180°C.”

The PrePro 2D can apply three thermoplastic composite tapes simultaneously and independently. “The machine is equipped with a 3-spool-applicator: three tapes with a width of 25 millimeters can be placed at the same time and also independently from each other at different times,” explains Emonts. “You can start with a first tape and then after some time start with a second and then, later, a third [as shown in the YouTube video above]. So you are not limited by placing three tapes simultaneously.” He says the advantage of placing each tape individually is increased productivity and reduced waste by achieving optimized near-net-shape laminates. “Because the tape feeds are independent, each is equipped with its own closed-loop tape tension control,” says Emonts.

A key feature of the PrePro 2D machine setup is that it is scalable. The customer can choose between different applicators (1-, 3-, 4-or 6-spool applicator), different widths for each tape (25-100 millimeters) and a different laser-setup. “The current machine is equipped with a 4-kilowatt laser system,” Emonts explains, “but for wider tapes or more spools (which will need more laser power) the system can be changed to higher-power lasers without requiring a different machine setup.”

The 1.5-meter table diameter can also be scaled to 2.0 meters. “Tape placement onto the table is done very precisely, with better than 0.2-millimeter accuracy, at full running speed,” says Emonts. “This is a cut-and-add-on-the-fly process. The laser is 500 millimeters away from the placement point and an optical camera provides closed-loop control of the laser power, tape tension and roller consolidation pressure to achieve in-situ consolidation.”

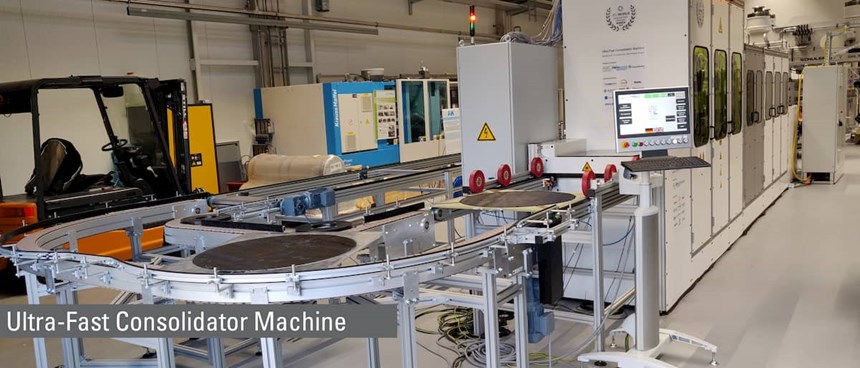

The small footprint and laser-safe cabinet of Conbility’s PrePro 2D enable flexible placement for high-volume production. Source | Conbility

Why is in-situ consolidation so important if the PrePro 2D is aimed at producing blanks to be used as inserts for injection molding? “Without in-situ consolidation, you must post-consolidate within energy- and cost-consuming subsequent processes” explains Emonts. “There are other solutions that tack the tapes together but then must melt the whole tape structure for subsequent consolidation, requiring an oven and a consolidation press. This is not needed using our machine system."

Micrographs of cross-sections from consolidated laminates made with PrePro 3D (left) and PrePro 2D (right). Source | Conbility.

Emonts contends that systems requiring secondary consolidation can cost more than €2 million. “But with ours, only the process zone is heated, so we get high-quality, consolidated laminates with less than €600,000 invested.” He notes the PrePro 2D also benefits from a small footprint — 5 by 3 meters — and is Class 1 laser-safe, “so it can be anywhere.”

The PrePro 2D is available at Conbility’s technical center in Herzogenrath, Germany (10 minutes from Aachen) for trials and job-shop manufacture of tailored composite blanks. “Even if companies just want to see the machine in action, we want to educate the industry about this laser-based approach and demonstrate that it is safe and user-friendly,” adds Emonts.

Low-cost, intelligent production opens future mass markets

“We have proven we can reduce injection molded part cost by adding a small amount of tape into the part,” notes Emonts. “We can produce parts that are 5-15% cheaper by significantly reducing wall thickness and getting rid of stiffening ribs. Thus, the injection molding tools get cheaper with less complexity. We also see tape prices decreasing because global production is steadily increasing.”

“We see huge potential in the automotive, electronics and many industries,” he continues. “Very simple parts, like boxes for handling in the food industry, can benefit from this approach. These must be cleaned, but stiffeners inside the box make cleaning difficult and more costly, while stiffeners outside prevent easy/efficient transport and handling. Our approach, however, can produce different thicknesses in one part and locally reinforce within a minimum thickness.”

Conbility sees a practically “infinite” number of injection-molded parts that can benefit from tailored blank composite inserts. Source | Slide 24, “Ultra-Fast Consolidator” and “OptoLIGHT” – Laser Technology enabling mass production of thermoplastic laminates and new hybrid production, presentation by Michael Emonts, Carbon Fiber 2019 (Nov. 19-21, Knoxville, Tenn., U.S.)

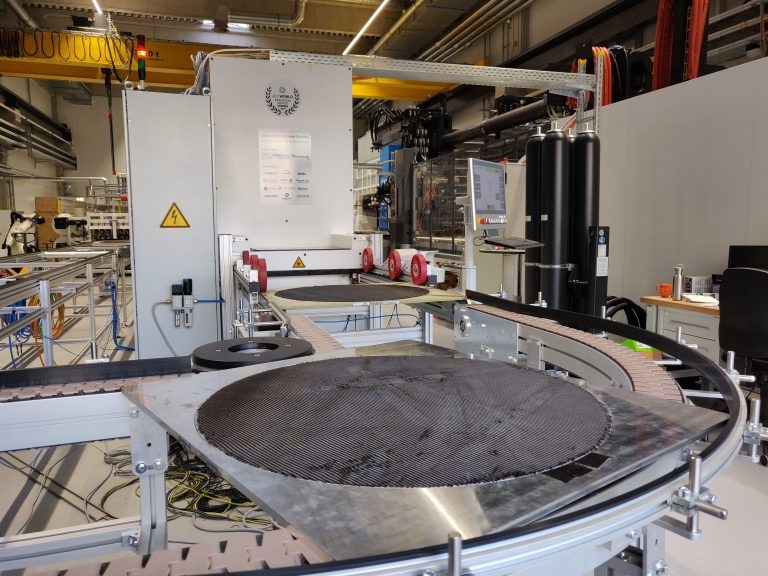

The Ultra-Fast Consolidator Machine uses Conbility’s AFP applicator to produce thermoplastic composite laminates in less than 5 seconds. Source | Conbility, AZL Aachen

Conbility’s AFP applicators are also being used in the Ultra-Fast Consolidator Machine, developed by AZL Aachen to produce multi-layer thermoplastic composite (TPC) laminates in less than 5 seconds. As noted in the July 2020 article, “Composites 4.0: Digital transformation, adaptive production, new paradigms,” this system uses 25-millimeter-wide UD tapes as well as a piece-flow principle — state-of-the-art in the high-speed printing industry — to produce TPC laminates, simply tacked or fully consolidated, in a variety of thicknesses, with local reinforcements. “Our vision is to provide scalable machines that will enable online platforms,” says Emonts. “Lines can have multiple stations, each with multiple AFP applicators. The customer will enter the requirements and get options for plybook, cost and delivery. Once finalized, the applicators communicate to each other to organize production, not the operator. This is completely intelligent production of tailored composites.

Ultra-Fast consolidator machine

Related Content

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More