Market Outlook

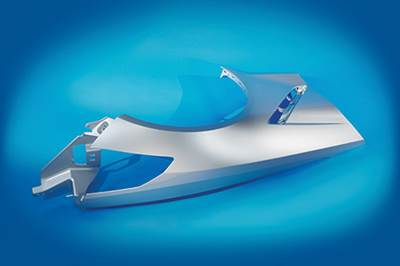

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

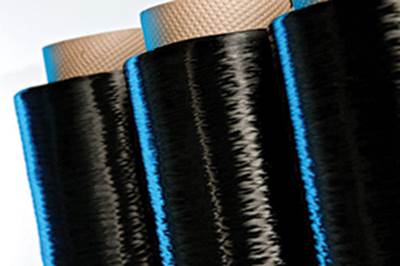

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreMaterials & Processes: Composites fibers and resins

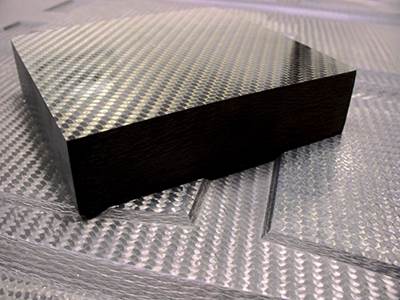

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreComposites end markets: Industrial (2022)

Composites often must meet a certain aesthetic in applications where the consumer is the end user. But fiber-reinforced materials are just as valuable in industrial applications where corrosion resistance, high strength and durability are the performance key.

Read MoreMaterials & Processes: Composites for repair

Composites offer cost-effective means to repair, protect and/or strengthen structures made of steel, concrete or other materials.

Read MoreMaterials & Processes: Composites part design

Designers of composite parts can choose from a huge variety of fiber reinforcements and resin systems. That makes knowledge of how those materials work together a critically important aspect of part development. Here's a short description of what that knowledge entails.

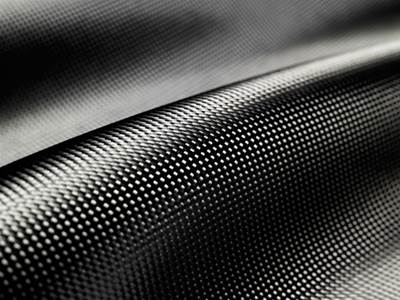

Read MoreMaterials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read More