Pressure Vessels

DNV GL issues provisional type certificate for GE Haliade-X

Selected as the preferred wind turbine for 4.8 GW projects in the U.S. and U.K., the Haliade-X is considered the most powerful in operation to date.

Read MoreVestas wins 50 MW order for largest Vietnam intertidal wind project

Vestas is supplying and supervising installation of 13 wind turbines made of composites, with the third quarter of 2021 the expected completion date.

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

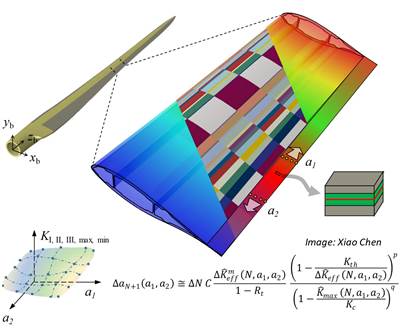

Read MoreFASTIGUE: Empowering digital twins of large-scale composite structures

A 3D finite element technique to resolve the fidelity-versus-speed dilemma of performing fatigue analysis for large composite structures.

Read MoreThicker, carbon fiber-reinforced battery electrodes may enable high-density batteries

University of Delaware research demonstrates use of carbon fiber membranes to enhance conductivity and areal capacity using a scalable manufacturing process.

Read MoreTech Table: Mold release agents

A table of mold release agents collected from data provided by suppliers.

Read MoreFill completes new center for digitalization and software engineering

Future Zone in Austria explores future of production machines, system intelligence, and virtual and real symbiosis.

Read MoreSky Advanced Materials fabrics win DNV-GL type approval

Certification for Hungary-based Sky Advanced Materials covers use of fabrics made with Zoltek PX35 50k tow carbon fiber combined with epoxy or vinyl ester.

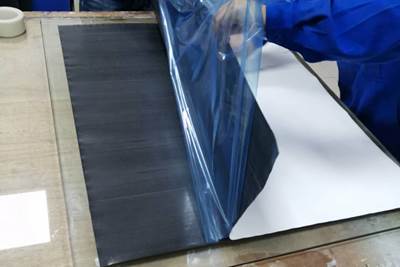

Read MoreSino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read MoreACT Blade, AMRC cooperate on 13m blade demonstrator

ACT Blade’s wind turbine blade design uses a textile shell overwrapping a structural spar to help reduce blade weight and manufacturing cost.

Read More

.jpg;maxWidth=300;quality=90)