Thicker, carbon fiber-reinforced battery electrodes may enable high-density batteries

University of Delaware research demonstrates use of carbon fiber membranes to enhance conductivity and areal capacity using a scalable manufacturing process.

Source | University of Delaware CCM

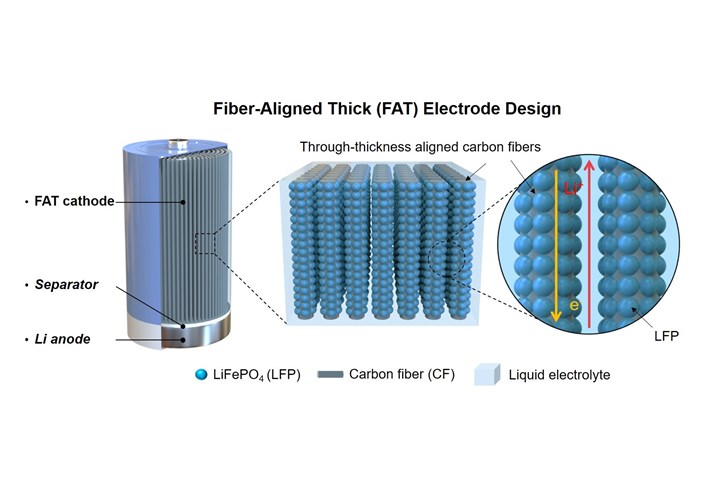

In a project published in the June 2020 issue of the American Chemical Society’s Nano Letters journal, researchers from the University of Delaware’s (Newark, Del., U.S.) Center for Composite Materials (CCM) have developed an ultra-thick battery electrode reinforced with vertically aligned carbon fibers. Called “fiber-aligned thick” or “FAT,” the new electrode design is said to exhibit enhanced properties and is easily scalable to manufacture.

“In a battery, the electrode is made up of an active material (the electrode material) and inactive components (e.g. metallic current collectors, polymer binders, and conducting matrix),” explains Dr. Kun Fu, assistant professor at the University of Delaware and an author on the study. In order to improve the specific capacity of a battery, he says, the amount of active material needs to be increased and the inactive materials decreased.

The FAT electrode designed by the University of Delaware Center for Composite Materials incorporates unidirectional (UD) short carbon fibers aligned in the direction of the electrode, with the active electrode material (LiFePO4, or lithium iron phosphate) embedded in between the fibers. The pores between the carbon fibers form low tortuosity channels through the electrode, allowing fast ion transport within the liquid electrolyte. “The FAT electrode uses aligned carbon fibers to construct a through-thickness fiber-aligned electrode structure with features of high electrode material loading, low tortuosity, high electrical and thermal conductivity, and good compression property,” Fu says.

Source | University of Delaware CCM

“In this case, a thicker electrode could significantly increase the ration of active material/inactive material, to achieve higher specific capacity,” he adds. The low tortuosity of FAT electrode enables fast electrolyte infusion and rapid electron/ion transport, exhibiting a higher capacity retention and lower charge transfer resistance than conventional slurry-casted thick electrode design.

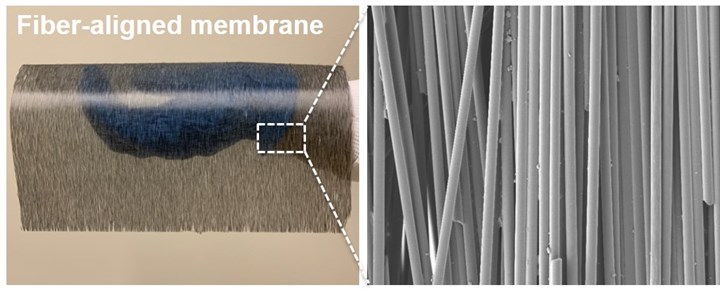

In addition to enhanced properties and higher capacity, the researchers say the manufacturing method is easily scalable and produced at low cost, involving an aqueous electrode ink and a cut-and-rolled carbon fiber membrane reinforcement. To manufacture the electrode, the carbon fiber membrane, which is loaded ahead of time with the active electrode material, is rolled up into a cylindrical shape and then cut perpendicular to the axial direction of the fibers. The researchers used this method to fabricate an electrode of 18 millimeters in diameter and a height of 55 millimeters for potential use in 18650 cylindrical battery cells.

Next, the researchers plan to apply the aligned carbon fiber framework to anode design, solid-state batteries, and Li-S and Li-O2 batteries, Fu says, and potential uses include batteries for electric vehicles, electronics or grid energy storage.

To access the study, go to the Nano Letters digital publication.

Related Content

-

SABIC launches fiber-reinforced, intumescent, fire-retardant resins

SABIC PP compound H1090 and Stamax 30YH611 resins are well suited for extruding and thermoforming large, complex EV battery pack components for automotive.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

Aptera joins forces with C.P.C. Group to accelerate solar EV production

Specialized composite bodies are being produced in Modena, Italy, for Aptera’s BinC vehicle, enabling eventual manufacturing ramp-up of 40 vehicles/day to meet demand targets.

.jpg;width=70;height=70;mode=crop)