Ketones

3D-printed composite wind blades and aircraft, closer than you think

Orbital Composites’ patented coaxial extrusion process is investigated at Airbus subsidiary CTC GmbH Stade and spins off advances in speed, scale, materials and multifunctionality as it aims for very large structures.

Read MoreOvermolding as enabler for composites, aerospace to automotive

CCP Gransden can make 50 to 100,000 parts/yr economically viable using PEEK, PPS, PEI or PA.

Read MoreCAMX 2017: Highlights from the floor

3D printing and nanotechnology developments promise to cut time and cost in composite structures production while recycling and sustainability continue to grow in importance.

Read MoreHexcel acquires Oxford Performance Materials

Hexcel (Stamford, CT, US) announced December 8, 2017 that it has entered into a definitive agreement to acquire the aerospace and defense (A&D) business of Oxford Performance Materials.

Read MoreVictrex opens new Polymer Innovation Center

Proactive investment in the development of next-generation thermoplastic solutions has now resulted in the completion of the company´s new approximately $13 million (£10 million) Polymer Innovation Center.

Read MoreRotomolded cores: New options for sandwich composites

Permanent or removable, these hollow thermoplastic cores broaden industry offerings.

Read MoreCAMX 2017 exhibit preview

ACMA and SAMPE’s fourth CAMX will be the largest composites trade show in the composites industry’s largest market. Held in Orlando, FL, this year, it promises an even more robust exhibition and conference program.

Read MoreCAMX 2017 preview: Michelman

Michelman (Cincinnati, OH, US), a developer and manufacturer of fiber sizing and resin modifiers, is featuring new fiber sizing formulations, including solutions suitable for use with glass, carbon and other structural fibers.

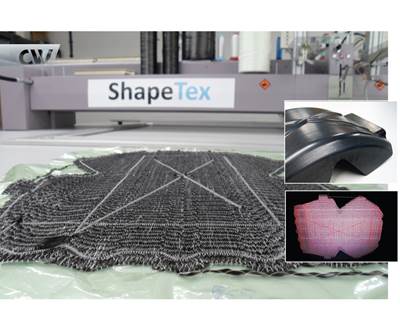

Read MorePreforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreArevo composite additive manufacturing: the future of AFP?

Its multi-axis, continuous fiber technology eliminates tooling, matches strength of titanium parts at 1/3 the weight and cuts part cost vs. hand layup/autoclave cure by a factor of 5.

Read More