Arevo composite additive manufacturing: the future of AFP?

Its multi-axis, continuous fiber technology eliminates tooling, matches strength of titanium parts at 1/3 the weight and cuts part cost vs. hand layup/autoclave cure by a factor of 5.

CW has covered Arevo Inc.’s (Santa Clara, CA, US) development of 3D printed composites for some time now. It touts the ability to build complex-geometry parts using chopped carbon fiber or, more importantly, continuous fiber-reinforcement and high-performance polymers like Ultem polyetherimide (PEI) and polyetheretherketone (PEEK). But its real innovation is coupling digital technology with a six-axis robotic platform to enable 3D parts with 3D fiber orientation.

“We are able to produce parts that weren’t possible previously,” says Arevo CEO Hemant Bheda. He claims the company’s composite additive manufacturing technology is now the lightest and strongest option to replace metal parts. “Our technology enables manufacturing large, complex parts that are too labor-intensive and costly with traditional composites,” says Bheda. “It also enables structural parts that are not possible with 3D-printed plastics. With fiber, we can construct a part to match the strength of metal, but offer dramatic reductions in weight.” He notes that with continuous carbon fiber reinforcement and high-strength thermoplastic polymers like PEEK, “we are starting with a material that offers five times the strength of titanium but at only one-third of the weight. These thermoplastic composites also offer excellent chemical resistance and toughness for more damage-tolerant structures.”

But why would the composites industry want to use this manufacturing method vs. more conventional processes? “Our technology eliminates tooling, its cost and its production time as well as the manual labor of current processes such as layup and vacuum bagging,” Bheda answers. He claims development is also much shorter and the process is simplified, going straight from CAD file to print, adding, “We can reduce the cost by a factor of five as compared to conventional composites processing,”

Bheda asserts that Arevo’s technology offers benefits not just compared to other composites processing but vs. typical 3D printing as well. “We can often eliminate the need for scaffolding,” he says. Scaffolding is material printed to support features that can't be built above open air, such as overhangs, undercuts and holes. “We have more freedom of direction to construct the part compared to other types of additive manufacturing,” Bheda explains.

Conventional 3D printing builds up parts by depositing material in XY planar layers, making them weak in the z-direction. This weakness is also inherent in conventional composites, which are prone to delamination between layup plies. “Our technology, however, exploits the power of digital engineering,” says Bheda, “allowing design and pre-production software to optimize the part construction, so that z-direction reinforcement can be added to planar material deposition.” He gives an example: “If you want to 3D print a complex-shaped aircraft duct, you can build it up layer by layer and then add traces vertically, circumferentially or locally as needed. Because our technology uses a 6-axis robotic arm, we have a high degree of flexibility in fiber deposition.”

Bheda reiterates the revolution possible due to this digitally driven production, “We simply define the envelope and load requirements, the software determines where to place the fiber and then applies it.”

Bheda gives another example of Arevo’s ability to print composite structures in multiple axes with full isotropy, “We can print the 3D contour of an aircraft wingskin." Is it possible to print the wingskin upside down with the stringers integrated as a single unit? Or better yet, stiffen it using some type of latticed cell structure between solid skins? "Yes, of course," he replies.

This last example implies a kind of hybridization between 3D printing and automated fiber placement (AFP) technology. “Precisely,” says Bheda, “except AFP requires tooling; our process does not.” Also, AFP inputs are at minimum 1/8 inch wide, which prevents construction of tight radii and small features in parts such as aircraft passenger seat frames.” He claims such structures are not practical with AFP, but would be with Arevo’s process. “We aren’t saying that we will take over all AFP applications,” he acknowledges, “but there are many applications that are not being addressed by AFP which we could accomplish now.” Bheda says Arevo has programs in place to take advantage of such opportunities, and will roll out new types of composite structures as these programs are completed. “We are very involved in developing secondary structure parts that are going inside aircraft,” he adds.

However, aerospace applications require qualification. “Carbon fiber and PEEK composite materials are already very familiar to the industry,” Bheda notes. “Only the process is new and must be qualified. We will have to partner with larger aerospace companies to make that happen.”

Does Arevo's recently announced partnership with IQT (see "Arevo and In-Q-Tel partner to drive high-volume composite manufacturing") help with this type of partnering? “IQT has done a thorough job of vetting our technology,” Bheda responds. “This partnership will help to open many doors which would be difficult for us as a small company. IQT is simply helping expose our technology capabilities to US Government customers.” From IQT’s point of view, it is a strategic investment into what they see as the future of advanced manufacturing.

Arevo looks at aerospace as strategic but understands it is a longer-term market. Thus, the company is also pursuing a variety of near-term opportunities, including consumer goods and industrial applications. “These can ramp up very quickly and often have requirements which are as challenging as aerospace structures,” Bheda observes. “If we can be competitive in the consumer marketplace to replace metal, we can tackle any application out there.”

Related Content

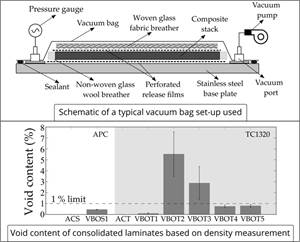

TPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

Read MoreMarkforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

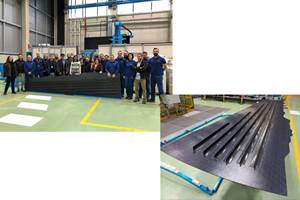

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More