Materials

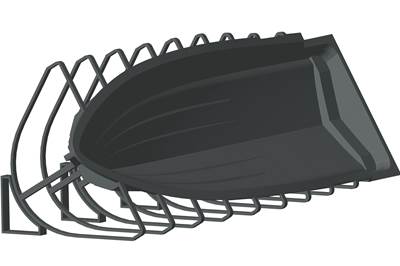

Thermwood demonstrates novel 3D printing approach for large vessel molds

Thermwood 3D-printed and trimmed five-foot-tall sections that were then bound together and bolted to form a complete female mold. The entire mold section, made of four printed pieces, weighs 4,012 pounds and required 65.5 hours to print.

Read MoreMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreSojitz invests in IsoTruss composite telecommunication infrastructure

The lattice telecommunication structure is equipped with the structural capabilities for bending and torsion and is corrosion-resistant, an advantage to coastal areas.

Read MoreReprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

Read MoreEpisode 34: Carmelo Lo Faro, Solvay Composite Materials

Carmelo Lo Faro, president of Solvay Composite Materials, talks about how he sees aerocomposites evolving in the time of COVID-19, the rise of computational power to evolve composites use, the prospects for increased composites use in the automotive market, and the increasing importance of education in the composites industry.

ListenHexcel third quarter financials reflect industry headwinds

Slowdown in commercial aerospace and the wind energy market has decreased Hexcel’s year-to-date sales by 32.6%. The company will close its wind energy glass fiber prepreg line in Windsor, Colo., U.S., in early November.

Read MoreAirborne Oil & Gas reinforces energy transition journey as Strohm

Rebranded as Strohm, the company works to confirm its commitment to the oil and gas sector’s goals to reduce the industry’s carbon footprint.

Read MoreNatural fiber crash box design for motorsport

The natural fiber Front Impact Absorbing Structure (FIAS) prototype showed desired crash behavior and eradication of sharp splintering, proving it as an alternative to carbon fiber in motorsport applications.

WatchEpisode 33: Ethan Escowitz, Arris Composites

CW Talks checks in with Ethan Escowitz, co-founder and CEO of Arris Composites, to learn about the Additive Molding technology his company has developed.

ListenVictrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Read More