Materials

Windform LX 3.0 composites contribute to OreSat0 CubeSat deployment

Portland State Aerospace Society, incorporating CRP Technology’s GFRP composite materials and SLS 3D printing, sent its CubeSat nanosatellite into low Earth orbit in 2021, where it continues to operate successfully.

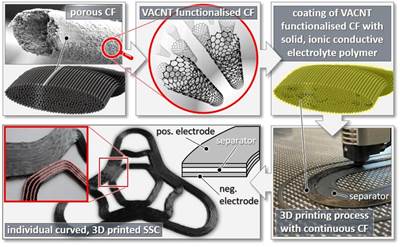

Read MoreRCCF of TU Dresden develops next-gen, 3D-printed structural supercapacitors

Thales Research and Technology leads PRINTCAP project for more sustainable fast-charging, structural energy storage for automotive and aerospace industries using multifunctional composite materials

Read MoreUniSQ fire-retardant resins development bolster bushfire mitigation

The University of Southern Queensland has received funding to be used in the development of cost-effective composite resins to increase the resilience of wind turbine blades against bushfire exposure.

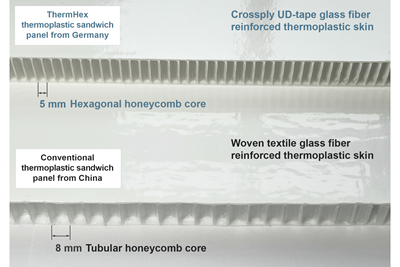

Read MoreThermHex Waben highlights thermoplastic honeycomb panels

Economically produced composite sandwich panels are sustainable while maintaining high mechanical performance and surface quality, driving them into new market applications.

Read MoreEuropean project EoLO-HUBs targets wind turbine blade recycling

The 18-member consortium will develop and use green chemistry processes to recycle composite materials and, among others, optimize the dismantling of wind farms through advanced software.

Read MoreAlauda Aeronautics debuts crewed flying race car

In a fusion of UAM and motorsport, the composite Airspeeder Mk4 is designed to set the bar for performance and technology for the Airspeeder Racing Championship in 2024.

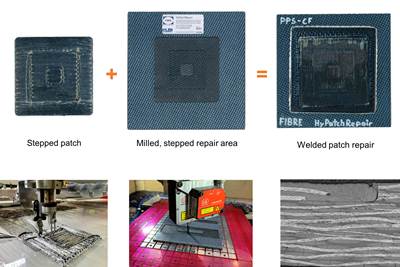

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreEuCIA participates in EU-funded REFRESH wind blade recycling project

REFRESH consortium aims to develop, demonstrate a novel system to enable improved recycling of glass fiber-reinforced composites derived from wind turbine dismantling or reblading.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

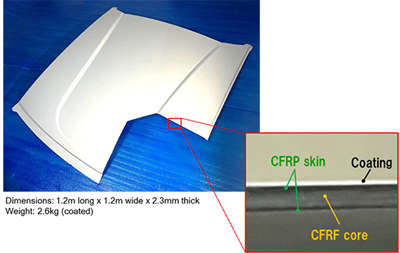

Read MoreToray develops rapid integrated press molding technology for CFRP mobility components

The process and material innovation simultaneously shapes, molds, thermosets and bonds the core and skin in the same mold, achieving this 10 times faster than conventional autoclave molding setups.

Read More