Materials

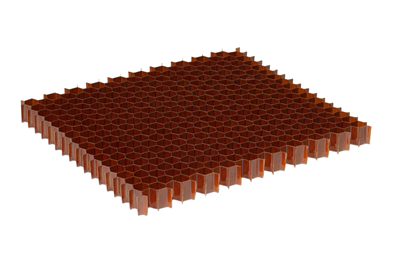

The Gill Corp. announces novel Gillcore HF fiberglass honeycomb core

High-temperature fiberglass-reinforced phenolic honeycomb core meets all AMS 3715 requirements with optimized moisture resistance.

Read MoreCycle Inspect introduces damage, risk assessment service to the composite bicycle industry

Australian startup seeks to bridge the disparity gap between carbon fiber bike ownership and specialists trained to inspect them via an ultrasonic non-destructive testing (NDT) and visual inspections procedure.

Read MoreCAMX 2022 exhibit preview: Kastilo Technical Fabrics GmbH

Kastilo highlights its specialization in PTFE-coated fabrics and belts, including its Magic Surface film lamination coating and PTFE-coated Multiple fabric/belts.

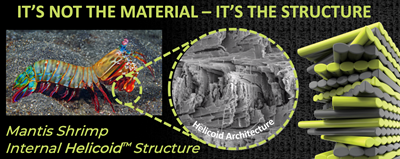

Read MoreCAMX 2022 exhibit preview: Helicoid Industries

Helicoidal fiber-reinforced composites are the inspiration for new developments in rain erosion-resistant substrates, improvement in damage tolerance and sustainable composites.

Read MoreCFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

WatchBoston Materials, Textron Systems to collaborate on hypersonic vehicle thermal protection system

Boston Materials will supply Textron Systems with its Z-axis Fiber technology to enhance performance of high-temperature composites that exceed 3,000°F.

Read MoreBoka Marine joins American Recreational Products portfolio, launches fiberglass boat line

The National Composites recreational watercraft line features battery- or solar-powered technologies with a fiberglass frame and room to hold four people.

Read MoreHORYZN emergency UAV harnesses CFRP tooling from Voith Composites

Voith Composites collaborated with HORYZN, a student initiative that leverages CFRP tooling and composites know-how for its Mission Pulse UAV project.

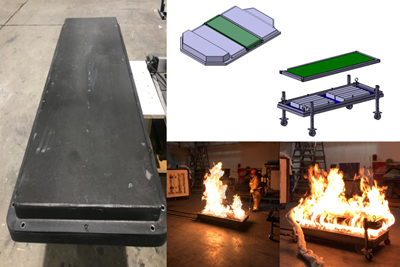

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreHyundai Motor, Supernal unveil eVTOL vehicle cabin concept

Concept details — such as CFRTP material incorporation, a biomimetic design and a focus on safety — provide a first look at how Hyundai integrate its mobility capabilities to develop commercial urban, regional air vehicles.

Read More

.jpg;maxWidth=300;quality=90)