The Gill Corp. announces novel Gillcore HF fiberglass honeycomb core

High-temperature fiberglass-reinforced phenolic honeycomb core meets all AMS 3715 requirements with optimized moisture resistance.

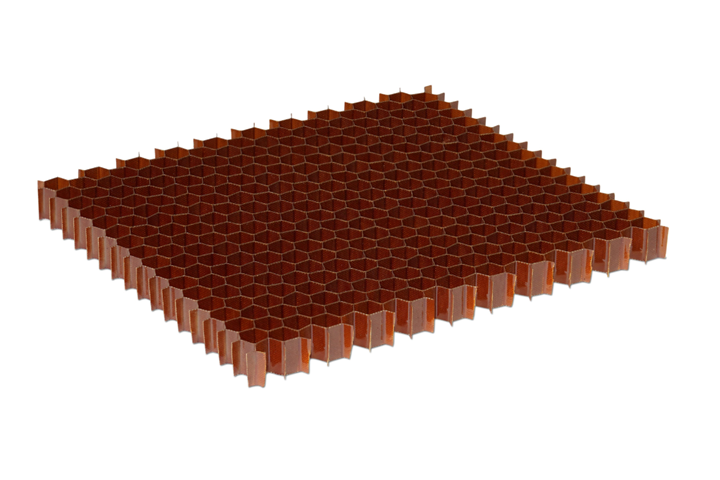

The Gill Corp. (TGC, El Monte, Calif., U.S.) announces the new Gillcore HF fiberglass honeycomb core, which, developed in response to industry demand from aerospace customers, meets all AMS 3715 requirements. The core is produced with a substrate consisting of woven fiberglass cloth reinforced with heat-resistant phenolic resin for improved moisture resistance over traditional aramid fiber substrates. TGC says it is suitable for high-temperature applications requiring a high degree of forming and high moisture areas.

TGC processes rolls of fiberglass cloth through the same manufacturing equipment as aramid honeycomb cores. In addition to completing its own AMS 3715 test requirements, the company is working with other customers to meet their own qualifications.

Testing performed includes:

- Plate shear strength and modulus, ribbon and transverse.

- Stabilized compression strength and modulus.

- Flatwise tension.

- 65F, RTA, 180F, 250F, 350F

- Wet – RTA, 180F, 250F, 350F.

Related Content

-

Designing an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

-

Angeloni launches non-stitched multiaxial NCF fabric option

An adhesive grants the same stability of traditionally stitched composite fabrics, making Stratos suitable for use in a range of fibers and production processes.