CAMX 2022 exhibit preview: Helicoid Industries

Helicoidal fiber-reinforced composites are the inspiration for new developments in rain erosion-resistant substrates, improvement in damage tolerance and sustainable composites.

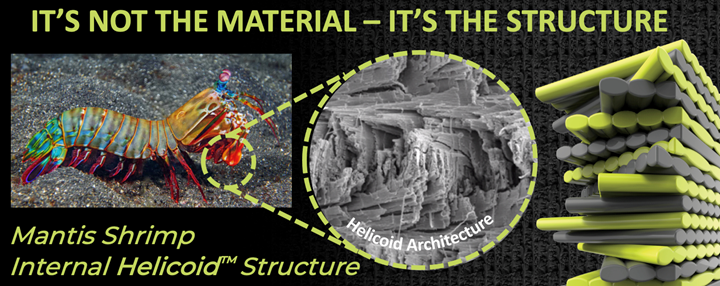

Helicoid Industries Inc. (Indio, Calif., U.S.) brings the Helicoid technology to the composites industry, showcasing updates for the few of many development projects the company is currently undergoing with various partners. Inspired by the “smasher” Mantis shrimp and the internal architecture of its hammer-like club, Helicoid consists of layers of aligned fibers which are stacked up with a progressive change in fiber orientation which leads to a helicoidal distribution of fiber orientation. Under impact, the company says the architecture steers and controls crack growth leading to highly diffused sub-critical damage. This enables the structure to dissipate energy while preventing catastrophic failure, resulting in high damage resistance and structural integrity. Helicoid Industries says this architecture is widely investigated at laboratory level across several academic institutions and is now being commercialized in several industries.

The company provides updates on its development for rain erosion-resistant substrates for wind blade applications, such as a fiber-reinforced substrate made of non-crimp fabrics (NCF) E-glass fabrics infused with epoxy resin, developed in collaboration with Saertex GmbH (Saerbeck, Germany). Helicoid Industries reports preliminary tests that are said to show a 34% erosion reduction compared to conventional NCF BX45 substrates (ASTM G73-10). An in-depth analysis with rain erosion tests performed at ORE Catapult (Glasgow, U.K.) reveals the effect of different parameters of the composite substrate in the mitigation of the rain erosion phenomenon.

This work adds to the development effort carried out in partnership with the University of California Irvine to optimize the Helicoid fiber architecture to improve damage tolerance of wind rotor blade skins. This collaboration targets the development of multiaxial Helicoid NCF fabrics for the manufacture of Helicoid NCF structural components for wind applications. Helicoid Industries says the development project will ultimately lead to a leading-edge protection solution for longer maintenance intervals and higher blade durability.

The company will present its latest developments on natural fiber composite performance improvement. Helicoid Industries was recently awarded a Phase I SBIR grant from the U.S. Department of Energy (DOE) to materialize its discoveries in improving performance of natural fiber composites into full-scale commercial products. The SBIR grant helps to accelerate Helicoid Industries’ ongoing development of a sustainable transportation industry, ultimately demonstrating the benefits of biomimetic composite innovation and technology in natural fiber composite products.

The project is being out as a partnership with Professor Lawrence Drzal at Michigan State University. As part of the technical developments on sustainable applications, Helicoid Industries displays how high-performance carbon fiber skins for padel and pickle ball rackets can be successfully replaced with natural fiber Helicoid skins. Reportedly, this replacement results in improved durability and a wider sweet spot area, increasing the playability performance of the racket.

Dr. Lorenzo Mencattelli, R&D director of Helicoid Industries, also presents the latest research activity in the field of sustainable Helicoid natural fiber composites and their hybrids, highlighting how biomimicry and Helicoid technology can be a viable and cost-effective way of enabling a more extensive use of sustainable materials in high-performance, high-volume applications

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.