Out of Autoclave

Composite Integration Ltd. moves to new, expanded facility

The RTM and resin infusion specialist will use the additional space at its Saltash, U.K. facility for R&D, training and larger machines.

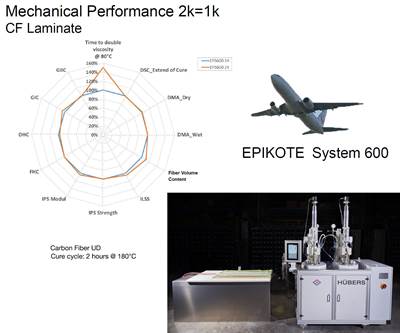

Read More2-part epoxy for increased composite aerostructures production via RTM

Hexion meets demand for accurate mixing with in-line analytic control while improving processing window, fiber volume content and manufacturing efficiency.

Read MoreAccelerating thermoplastic composites in aerospace

ATC Manufacturing produces millions of thermoplastic composite parts per year, and is investing for future growth.

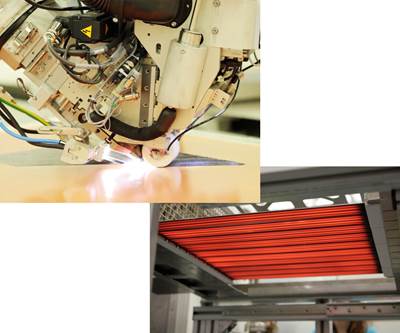

Read MoreInnovating energy delivery for more efficient composites manufacturing

Heraeus Noblelight develops HUMM3 and Black IR technologies for faster, safer, more uniform processing.

WatchCan the automotive industry turn to face the change?

SPE ACCE speakers speculate about how changing consumer behaviors might shape the automotive industry.

Read MoreDisruptive composite tubing manufacturing

TUBETEC delivers high-performance, hollow composites in unimaginable shapes with beautiful surface finish, fast turn-around and affordability.

Watch5G-enabled smart cities bring opportunities for pultruded composites

A recent report explores the utility of radio frequency-transparent pultruded composite materials for integrating 5G mobile networks into urban infrastructure.

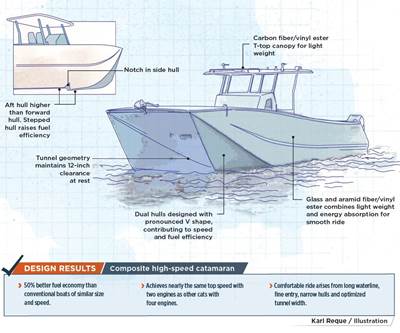

Read MoreComposite catamaran hits high watermarks

Inspired by design elements found in racing catamarans and employing composite structures in innovative ways, Compmillennia has rolled out a fishing/excursion cat that uniquely combines high speed, great fuel economy and a smooth ride.

Read MoreCAMX 2019: Exhibit previews, part 2

CAMX 2019 is just around the corner, so it’s time to start thinking about what you will encounter on the show floor. This is part two of a two-part series that previews some of the products, technologies and services that will be on display.

Read MoreSwancor to supply MHI Vestas with wind blade materials in Taiwan

The supply contract covers more than 50% of the direct materials value of blade manufacturing, including carbon tow, carbon pultrusion, resin and bonding glue.

Read More