2-part epoxy for increased composite aerostructures production via RTM

Hexion meets demand for accurate mixing with in-line analytic control while improving processing window, fiber volume content and manufacturing efficiency.

Share

Read Next

Welcome! You’ve unlocked premium content.

This is the third in my series of blogs about technologies you should check out at CAMX 2019 (Sep 23-26, Anaheim, CA, U.S.). Hexion (Columbus, Ohio, U.S.) has developed a two-component (2K) system for RTM of aerostructures based on its Epikote System 600 epoxy resin. The introduction below will explain why this development is important. After that, I give more details on this new 2K system and how Hexion is meeting aerospace OEMs’ demands for in situ quality assurance of the mixed resin. At bottom, I also discuss Hexion’s 2K infusion/RTM epoxy for fire-resistant (FR) applications.

Why 2K resins for RTM?

Earlier this year, I wrote about programs at tooling specialist Alpex Technologies (Mils, Austria) and Airbus subsidiary Composites Technology Center (CTC, Stade, Germany) to produce composite aircraft parts using resin transfer molding (RTM). Using RTM in aerospace is not new. There are and have been a variety of aircraft parts made using RTM, including:

- Rudder for the Gulfstream G250 business jet (Israel Aerospace Industries and North Coast Composites)

- Blades and fan case for the LEAP turbofan aircraft engine (Albany Engineered Composites)

- A350 door frame (Airbus Helicopters Donauworth)

- Demonstration A350 passenger door (Elbit Cyclone)

- Demonstration A320 multispar flap (Airbus Bremen)

- Matrix Composites produced more than 6,000 components for the F-22 using RTM.

However, RTM in aerospace applications has traditionally been a low-pressure process with cycle times measured in hours. The programs at Alpex and CTC are focused on exploiting the automation, fast injection and 15- to 20-minute cycle times offered by high-pressure RTM (HP-RTM). In my article “HP-RTM for serial production of cost-effective CFRP aerostructures”, I discussed the issue of using 2-component (2K) epoxy resins versus the current norm of using premixed, 1-component (1K) systems:

“Schiller [Jan Schiller, CTC project leader for production systems and lead contact for RTM technologies] observes that all previous RTM aircraft structures have only used 1K systems mixed by the supplier, who then certifies the mixture and bears the liability for making sure the resin meets qualification requirements. “Now we are considering 2K systems, but the challenge is to ensure the mixing quality,” he explains. Premixed 1K systems require cold shipment and storage to prevent reaction until part processing. Thus, advantages of 2K systems include elimination of this expense as well as higher reactivity for faster processing.”

“One issue, however, is that quality assurance (QA) will transfer from the resin supplier to the parts manufacturer. “This QA requires detection of the mixing ratio and the mixed resin quality. Both are needed for Airbus qualification of a new material. So, this means measurements of the two components just prior to mixing and of the resin after mixing. Today, we only have sensors before the mix head, showing how much resin and how much hardener are metered into the mix. This is not enough for qualification.”

Hexion (Columus, Ohio, U.S.), a leader in developing fast-cure epoxies for HP-RTM in automotive composites (see “HP-RTM on the rise”), announced in March 2019 that it has developed a 2K system for RTM of aerostructures based on its Epikote System 600 epoxy resin. I interviewed Hexion’s Epoxy Global Aerospace Segment leader, Jean Rivière, to learn more about their 2K system for aerospace and how they are meeting this demand for in situ QA of the mixed resin.

Overcoming limitations of 1K systems

“Just like with prepreg, the 1K systems for RTM and infusion in aerospace must be kept cold and have a limited shelf life,” says Rivière. “By using a 2-component (2K) epoxy system, you remove these constraints. We have seen 2K and highly reactive epoxy resins used in the manufacture of wind blades and automotive structures. So why not in aerospace?”

Rivière explains that after talking to many customers about this, Hexion understood the main concern — you need a validation that the mixing ratio is correct at any time before the injection into the mold. Without this you havean unacceptable risk for the part manufacturer,” he notes. He adds that previously, there wasn’t a demand for the type of production volumes seen in wind blades and automotive. Now, however, Airbus and Boeing want to exceed current production rates while aiming for more composite parts per aircraft. “So now there is a need to move away from prepreg layup and toward a 2K epoxy for aerospace RTM or infusion,” says Rivière.

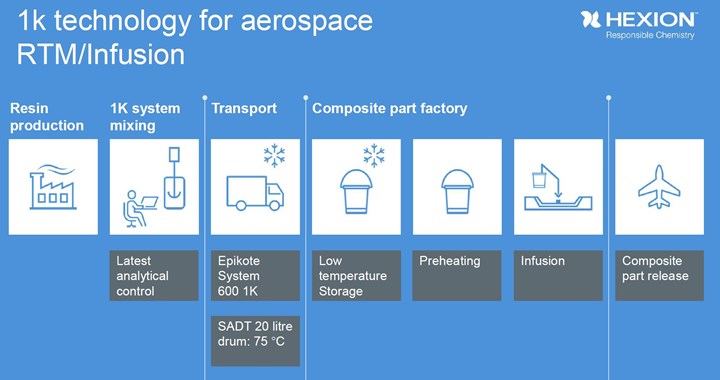

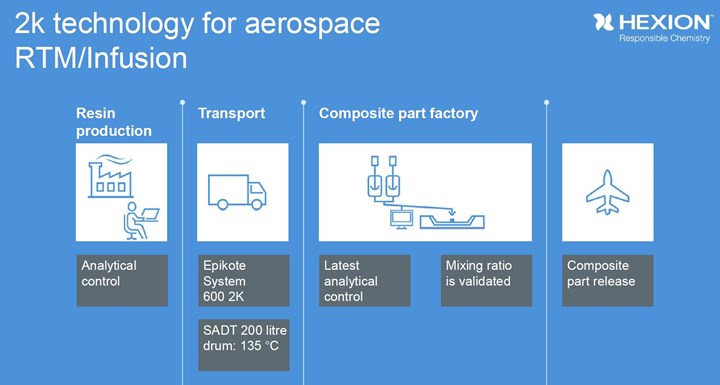

In the supply chain diagrams below, 2K technology not only removes cold storage and rewarming steps, it also lifts restrictions on resin container size for shipment. “You must keep premixed resin mass down to 20 liters and maintains those drums at very low temperature,” says Rivière, “or else the resin can start to react. For a 2K system, standard 200-liter drums can be shipped without low temperature restrictions. So, there is less risk, no strong cooling and less precautions needed.”

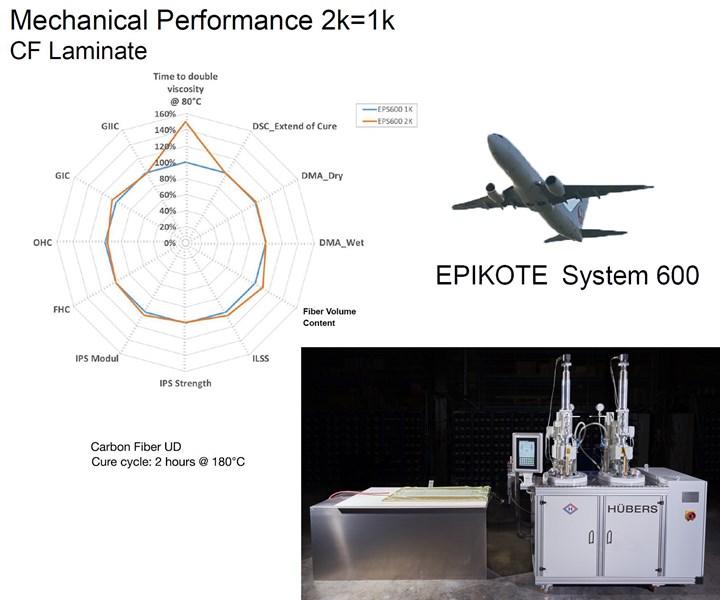

The supply chains above show how analytical control changes. While only an initial control is performed at the manufacturing location for 1K resin systems, control is implemented at multiple control points for the 2K system. In addition to control of A and B components during factory production, the A:B mixing ratio is also controlled digitally in the mix, meter and dispense (MMD) equipment and again just prior to resin injection into the mold. SOURCE | Hexion.

Analytical control

To develop this 2K technology, Hexion worked with Hübers (Bocholt, Germany), a manufacturer of mix, meter and dispense (MMD) equipment, and Composyst (Hurlach, Germany) which has an exclusive license for the Airbus-patented Vacuum Assisted Process (VAP) for infusion. Hübers has a strong reputation for high-performance MMD systems used in the manufacture of electrical and electronics components (e.g., cast resin and impregnated components for transformers, etc.) while Composyst is an expert in resin injection and infusion for Airbus applications, and thus, understands what the aircraft OEM is looking for with regard to processing and quality assurance (QA) of mixed resins.

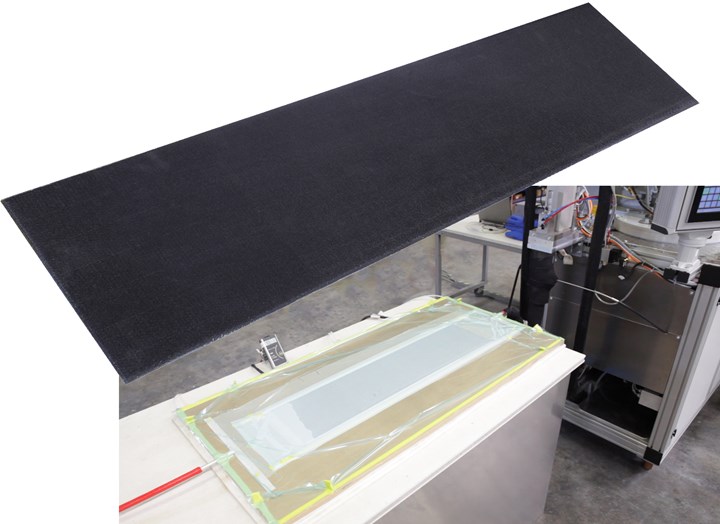

“The analytical control comes into play after the A and B components of the epoxy have been mixed precisely by the Hübers equipment and are preparing to be introduced into the mold,” Rivière explains. The black tubes between the Hübers MMD system and the vacuum-bagged VAP infusion setup in the image below are a key component of this analytical control system. “This is where we have an analytical device that controls the mix ratio in real time,” says Rivière. “We have demonstrated mix ratio measurement every 12 seconds, but more frequent measurement is also possible. Indeed, the technology enables a continuous control of the mixing ratio, which is reported and logged.”

Note black tubing between the Hübers MMD equipment and the VAP infusion setup where Hexion has developed in-line measurement of the resin mix ratio prior to injection. SOURCE | Hexion

“With this system,” he continues, “there is a double control: the normal control in the MMD unit and our pre-injection analytical control on top. First, Rivière points out that the Hübers MMD machines are well-known for their precision and accuracy. “They have a double pumping system for the two components and must maintain accuracy in volume and temperature as well as mix ratio for applications they supply into. Our system then adds a second measurement after mixing and just prior to injection where you can set targets for alarms.” Should the measured mix ratio not meet the targets and trigger the alarm, the system will then evacuate the mixed resin into a separate vessel, bypassing the mold so that it is not introduced into the infused part. “It is then possible to recover the process and continue injection,” notes Rivière.

He says Hexion’s post-mix, pre-injection analytical control system provides an independent record for traceability and can also be integrated into the MMD unit, depending on the customer’s needs. Rivière notes that the Hübers MMD unit also performs thorough degassing of the resin, which is required by the electronics industry, where there can be no voids or porosity in the application components. “This system also provides portable control of the pressure on the mold by managing the flow of the resin at high or low levels,” he points out. “You can achieve very good impregnation with this type of control, and you can also shorten the infusion process time while meeting aerospace quality requirements in terms of porosity and fiber volume.”

Photos showing infusion setup using Hübers MMD equipment and Hexion 2K analytical control and a 2-centimeter thick carbon fiber UD laminate prepared using this setup, achieving more than 60% fiber volume. SOURCE | Hexion

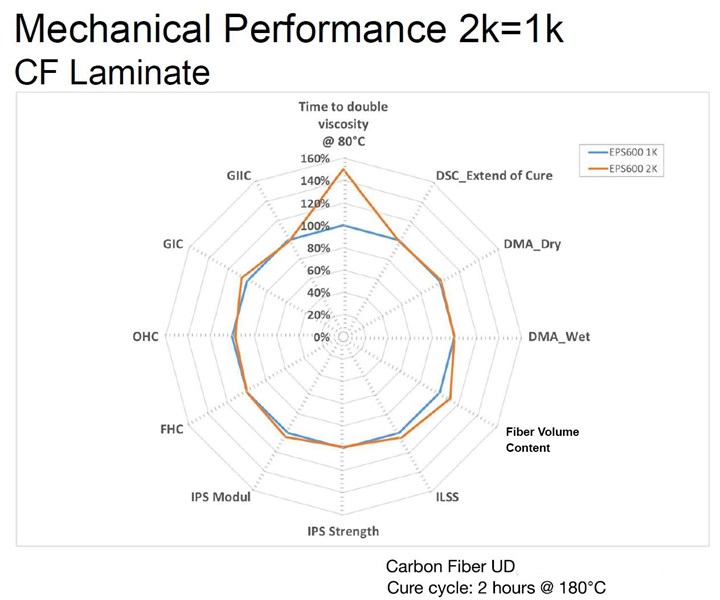

Better processing window

“Because the mixing is done with a static mixer and in a short time frame just prior to the injection, the resin mix offers a longer pot life (up to 40% when compared to 1K),” Rivière notes. This provides a better processing window and we have produced thick carbon fiber laminates with 60% fiber volume. The mechanical performance of the 2K versus 1K systems are the same because the chemistry is the same. We believe this will be a more reliable process and the complete value is when you connect the mixing control to the resin injection setup.”

SOURCE | Hexion

Hexion will be presenting detailed information on both its 2K Epikote 600 system for RTM and its EPON FlameX epoxy for meeting aircraft fire, smoke and toxicity (FST) requirements (see below) in the CAMX Theater on the exhibit floor:

- Novel 2K Technology for Epoxy Aerospace Manufacturing

Tuesday, Sep. 24 — 11:00 -11:25 am - FlameX Epoxy Systems for Fire Safety Applications

Tuesday, Sep. 24 — 11:30 – 11:55 am

You can also get more details at the Hexion booth Y24.

EPON FlameX epoxy for infusion/RTM of fire-resistant composites

Hexion has also developed a 2-component epoxy for infusion/RTM of parts that must meet fire resistance (FR) and flame, smoke, toxicity (FST) requirements. Aimed to replace phenolic prepregs with epoxy liquid molding, drivers for this development include:

- Increased production rates

- REACH regulations for halogen-free, non-phenolic systems

- Stronger, tougher resins versus brittle phenolics

- Cost-competitive with phenolics but much cheaper than thermoplastics.

Hexion’s EPON FlameX system does not use halogen or particulate additives to achieve fire resistance, but instead builds that performance into the resin’s molecular backbone. There is no particulate filtering during infusion, The resin infuses well with a viscosity of 250 cps at 60-70 °C (140-158 °F) and cures in 1.5 hours at 150°C (302°F). Freestanding or tool-supported post-cure at 180°C is recommended for maximum structural properties.

Parts made with this system pass the following with no additional coatings or FR measures:

- 60s vertical burn FAR25.853(a)

- Smoke toxicity BSS7239

- Smoke density BSS7238

It will also pass OSU 65/65 heat release, in certain configurations with a certified intumescent gel coat or coating. This is required only for parts that can be touched during aircraft taxi, takeoff and landing.

“We have demonstrated overhead bins that currently require 10-12 hours to manufacture using conventional phenolic prepreg processes but can be produced in 90 to 120 minutes with infusion or RTM using the FlameX system,” says Nathan Bruno, Hexion epoxy applications and product development specialist. “Also, because there are no fillers, it has a lower density versus filled FR epoxies.”

Applications include aircraft interiors, cargo areas, lavatories, galleys and seat components, as well as marine, rail and architecture interiors.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)