Processes

Pultrusion picks up speed in automotive applications

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts.

Read MoreThermwood announces larger melt core for its LSAM systems

The higher output capability of the 60-mm melt core enables 3D printing of layers with 250 ft or more bead length with most polymers.

Read MoreMoi recognized for 3D printing with continuous fiber

Moi composites is the overall winner of the Italian National Innovation Award (Premio Nazionale Innovazione) for its additive manufacturing technology.

Read MoreComposites One to distribute Solvay process materials and tooling products

Solvay has appointed Composites One as a new North America distributor for its process materials and tooling product lines.

Read MoreDark Matter Composites announces 2019 course schedule

Consultancy and composites design and prototyping service provider offers composite training courses.

Read MoreThe democratization of composites

China as springboard to push adoption of thermoplastic composites and revolutionize consumer goods.

Read MoreNAIAS hosts Additive Manufacturing Workshop for Automotive

The Additive Manufacturing Workshop for Automotive (AMWA) will take place on Jan. 16 at the North American International Auto Show (NAIAS).

Read MoreMikrosam delivers multi-material AFP system to Brandenburg University of Technology

The 8-axis robotic AFP machine is reportedly capable of automated and precise placement of thermoplastic fibers, thermoset prepregs and dry-fiber material.

Read MoreFinepart Sweden waterjet system enables precise, non-thermal cutting

Finepart Sweden’s micro abrasive waterjet system offers non-thermal micro cutting for composites in a variety of applications.

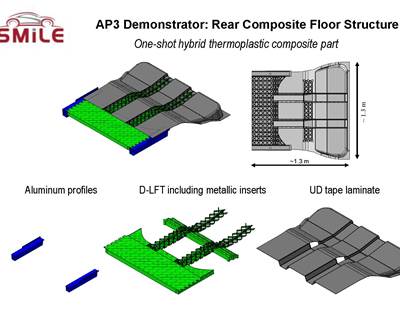

Read MoreContinuous tapes, D-LFT meet up in new compression molding process

Design research for an automotive load floor module drove development of a new compression molding process for direct-long-fiber thermoplastic (D-LFT) composites.

Read More