Pultrusion

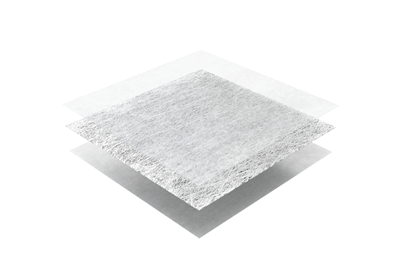

Ilium FLEXmat fiberglass is suitable for pultrusion processes

Latest long chopped glass fiber reinforcement technology enables high temperature exposure, material stretching and chemical resistance, making it a safer cleaner option for pultrusion manufacturing.

Read MoreExel Composites pultruded rods enhance Umbrosa parasol durability

The Belgium-based manufacturer chose pultruded fiberglass ribs for many of its umbrella and parasol designs to effectively endure exposure to high wind speeds, saltwater, rain and UV.

Read MoreGerman consortium develops biopolymer-based Cellun composite

German Institutes of Textile and Fiber Research (DITF) and partners present a conventional composite material alternative using cellulose that can be processed using industrial processing methods.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

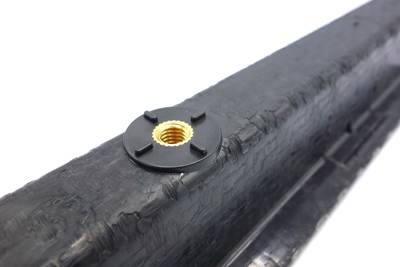

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreCreative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

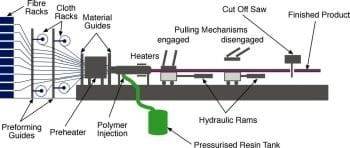

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreTNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.

Read MoreKent Pultrusion expands manufacturing facility to address the growing composite market

Doubled capacity increases the fabrication, machining and assembly capabilities for Kent’s servo motor-controlled ServoPul pultrusion lines.

Read More