Resins

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreSeaBioComp project develops biocomposite demonstrator products for marine applications

Prototype products explore thermoplastic polymers, natural fibers and 3D printing technologies to effectively reduce the use of fossil-based materials in the marine sector.

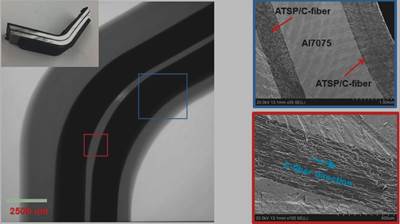

Read MoreNew polymer expands composites options in demanding environments

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

Read MoreThermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

WatchLimited edition watch features carbon fiber case produced by 9T Labs

Using its Additive Fusion Technology, 9T Labs mass produced 1,000 units of the watch case from continuous carbon fiber-reinforced PEKK, achieving a strong, ultralight, aesthetic product.

Read MoreThe importance of resin mixing procedures in the composites shop

What is considered to be common knowledge when storing, handling, weighing, mixing and deploying epoxy resins and adhesives has brought to light the need for tighter control, improved practices.

Read MoreGrand Largue Composites, Sicomin enable flax fiber-built Class40 racing yacht

Fibers, fabrics, epoxy resins and adhesives from Sicomin helped realize the lightweight, strong and stiff Crosscall yacht, capable of tackling extreme ocean racing conditions.

Read MoreNovel composite aims to resolve self-healing material challenges

University engineering researchers have developed and tested self-healing composites capable of self-repairing in place repeatedly without losing healing properties, as well as enhancing resistance to fracture.

Read MoreDigital Demo: The Advantages of Thermoplastics Technology

From stronger, longer-lasting parts to creating sustainable options for composite parts, this demo will pique your interest in this emerging technology. (Sponsored)

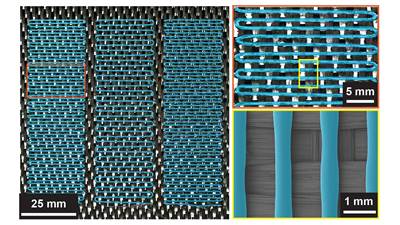

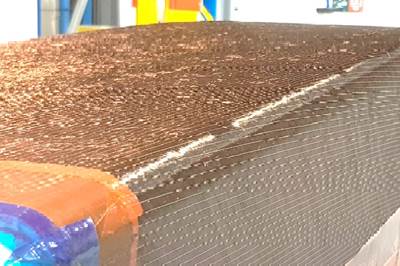

WatchOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read More