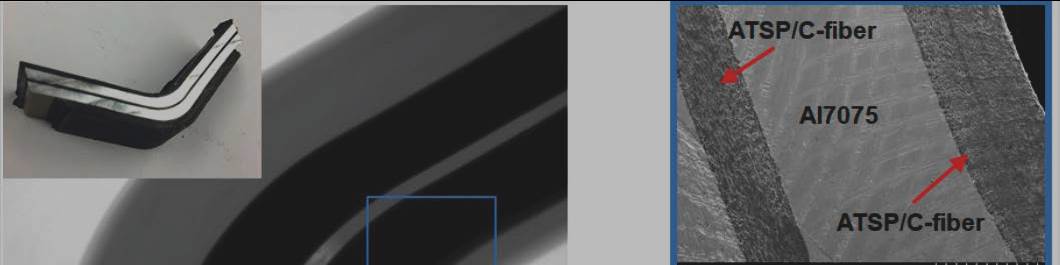

One of the first applications where ATSP polymer is being considered is for a NASA-funded project involving rollable or foldable composites for deployable structures. In order to participate, late last year ATSP Innovations sent polymer in film form to a prepregger who successfully impregnated a thin-ply, plain-weave carbon fiber fabric. Photo Credit, all images: ATSP Innovations Inc.

One hundred and sixty years after Alexander Parkes introduced the first human-made plastic at the London International Exhibition, and 115 years after Leo Bakeland created the first fully synthetic and commercially successful polymer, development of new resin systems — as opposed to novel blends and alloys of existing polymer families — are no longer a common occurrence. Hence, when an organization introduces a new polymer — especially one with a unique combination of properties enabling the material to be used in a variety of applications and supplied in many form factors — it’s worth paying attention. Such is the case with a new-to-industry resin system that was invented 12 years ago by Dr. James Economy, a long-time professor and former head of the Department of Materials Science and Engineering at the University of Illinois at Urbana-Champaign. Economy passed away at the age of 92 in the fall of 2021

Called aromatic thermosetting copolyester (ATSP), the novel resin technology is owned by ATSP Innovations Inc. (Houston, Texas, U.S.). The material was introduced in a technical presentation at the 2021 Society of Plastics Engineers (SPE, Danbury, Conn., U.S.) Automotive Composites Conference & Exhibition (ACCE) last November. We sat down with presenter Dr. Jacob Meyer, ATSP Innovations’ co-founder and vice president technology, and Economy’s former student, to discuss the polymer’s unique properties and some potential applications currently being investigated.

Thermoset and thermoplastic properties

ATSP is a non-catalyzed, condensation-cure polymer system combining continuous amorphous and liquid crystal segments. As such, it offers an interesting hybrid of properties commonly found among thermosets and thermoplastics. For example, like thermosets, once polymerized and cross-linked, it offers high thermal and broad chemical resistance and tight control of dimensional stability. Its glass transition temperature (Tg) is more than 250°C and it doesn’t thermally degrade at temperatures below 500°C, meaning it’s ideal for use in truly demanding environments where most polymers have long since melted or fallen apart.

However, like thermoplastics, it offers good processability, post-mold “weldability” and melt reprocessabilty, enabling scrap and end-of-life (EOL) parts to be recycled. It softens between 170-180°C, is an uncured liquid between 230-240°C, begins curing at 270°C and is fully cured at 340°C. Depending on form factor and how fast one wishes to heat and cure the polymer, heat sources such as infrared, microwave and induction may be used. Even its mechanical properties blend the best of thermosets (tensile modulus of 4.2 GPa) and thermoplastics (8-10% strain to failure).

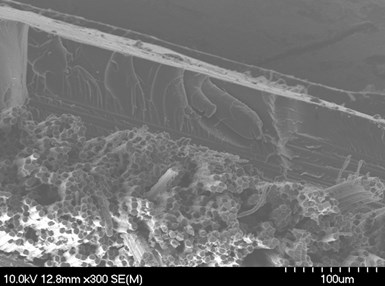

The scanning electron micrograph (SEM) image at top, shows that a fracture has occurred entirely in the matrix at 90° to the carbon fiber tow, as no broken fibers are observable. This indicates that failure was matrix-dominated and the material demonstrated high fiber/matrix interfacial shear strength. The SEM image on the bottom shows resin still intimately bonded to fibers at the fracture surface.

Since it’s aromatic — meaning it starts as a ring structure — and an oligomer, heat application of 270-340°C prior to polymerization leads to a rapid drop in viscosity (this varies by formulation, but is on the order of 4,000-10,000 centipoise), enabling ATSP to wet out a wide variety of fibers, including carbon, glass, basalt and natural fibers. In fact, Meyers says ATSP has produced carbon fiber-reinforced composites with up to 70% fiber volume fraction (FVF). He says the material also offers excellent bonding to a variety of nanoparticles, including graphene.

In neat form, ATSP has a specific gravity of 1.32. It’s said to have low outgassing, be free of volatile organic compounds (VOCs) and be without environmental, health or safety concerns. Equally interesting, it possesses a long shelf life with no need to refrigerate or freeze. In fact, Meyer recalls finding a batch of ATSP powder that had been sitting on a shelf for three years and successfully producing a cast film with it.

A good electrical insulator, neat ATSP has a dielectric constant of 5.0 at 25°C and 10 kilohertz, and a dielectric breakdown strength of 384.4 volts/micrometer. The material also offers high oxidative stability, easy machinability with low dust (helpful when machining shapes) and a very low moisture absorption rate of 0.2-0.3%.

ATSP also has excellent and inherent non-halogenated flame retardancy with a limiting oxygen index (LOI) of 40% and UL 94 V-0 listing at 1.5 millimeters. When exposed to an open flame, Meyer says the polymer forms a stable char, which insulates unburnt material below. Additionally, it offers high lubricity and low wear, making it interesting for tribological applications.

Perhaps its most notable feature is something called solid-state interchangeable/exchangeable bonds, a function of interchain transesterification reactions (ITR), which enable previously cross-linked parts to be “welded” together like a thermoplastic after applying heat (in the range of 270-340°C) and pressure (average 1-4 MPa). Want to separate those cohesively bonded pieces? Just bump the heat up again and pull them apart.

Many form factors, potential applications

Meyer says that the polymer can easily be tailored to produce specific properties, which also enables ATSP Innovations to offer the material in multiple form factors and to explore its use in a broad range of potential applications.

For example, it can be supplied as prepolymers (which can be solvated), pre-cured bulk sheets or shapes (blocks of solid neat or reinforced polymer used to machine rather than mold parts), or as a structural composite in the form of B-staged molding compounds with discontinuous fiber or composite laminates with continuous fiber architectures. Additionally, it’s also available as a powder or film for coating or impregnating other materials.

Besides its use as a structural composite, which is of interest in aerospace and automotive markets, ATSP is currently being evaluated as a high-performance melt- or solvent-spun fiber. It’s also being studied as an open-cell foam (with foaming produced as a natural byproduct of the condensation-cure reaction). While researchers have only achieved a density reduction of 0.2 grams/cubic centimeter to date, the fact that ATSP foam provides sound damping plus excellent thermal insulation (0.10 watts per meter-Kelvin) and flame retardancy makes it interesting as a high-temperature barrier material or the core for a sandwich panel composite for customers in building/construction, infrastructure, aerospace and automotive where it could potentially compete with polyimide foams.

Furthermore, ITR can be put to use by creating a structural adhesive with high shear strength (20 MPa at 80 microns thickness) over a broad temperature range. As an adhesive, the material (in powder coating form) is transparent, fast bonding, offers excellent adhesion to a broad range of industrial materials, including polymer composites, aluminum, steel and glass, and comes with the thermoplastic-like advantage of being able to be bonded, unbonded and rebonded multiple times without losing properties. In fact, the non-tacky bonding process can be done in the field without use of gloves or other personal protective equipment (PPE). Reportedly, the adhesive technology was developed in collaboration with NASA (Washington, D.C., U.S.) for potential use in space assembly operations.

On the left is an X-ray computed tomography (CT) image of an interchain transesterification reaction (ITR)-bonded carbon fiber-reinforced ATSP composite/AI7075 multi-material laminate with a curved geometry. On the right are two SEM images taken of the cross-section area of the sandwich construction.

Still another application area the company is exploring is production of high-performance polymer bearings with an ATSP film/coating that has been formulated for extreme working conditions of high loads, high speeds and high temperatures. And ATSP can even be formulated for 3D printing, opening up additional opportunities.

Aerospace and oil/gas customers are said to be interested in ATSP as a replacement for polyetheretherketone (PEEK), polyetherketoneketone (PEKK) and polyethersulfone (PES). Transportation OEMs are reportedly interested in it as a replacement for para-aramid-reinforced ballistic panels. N

Next steps

“ATSP has such a unique combination of properties that our biggest challenge isn’t finding an interesting application or two, but rather to focus on just a few areas — like composites and adhesives — that are likely to be easier to implement and can help us commercialize this polymer at last,” Meyer explains. ATSP Innovations is currently working with Allied Composite Technologies LLC (Rochester Hills, Mich., U.S.) on business and application development and licensing. The polymer is also being strategically sampled in the aerospace, automotive, building/construction, infrastructure and oil/gas industries. The first commercial applications could be seen as early as next year. In the meantime, Meyer says ATSP Innovations is actively seeking and engaged with prospective partners, collaborators and customers to help bring this technology to market.

Asked where he anticipated pricing would be for ATSP once commercialized, Meyer adds, “This is in large part a matter of scale, but our long-term goal is to be competitive with nylon (polyamide) and our nearer-term, more conservative price points should still be viable for pilot-level production.”

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)