Wind/Energy

Vestas looks to scale up blade recycling partnership solution offering to U.S. and other regions

Vestas seeks areas where local recycling infrastructure is robust, and customer demand can be established. Recycling methods can include cement co-processing, gasification, development of new composite materials and reclamation.

Read MoreMaersk Supply Service to install Gazelle Wind Power offshore wind pilot plant in Canary Islands

Two-megawatt plant will use Gazelle’s hybrid floating wind platform, established to be robust and simple to build, deploy and maintain in deep waters.

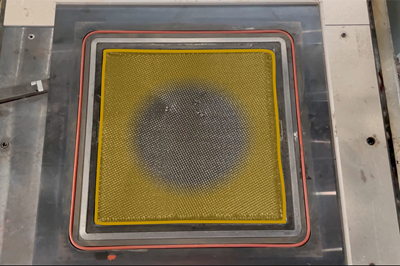

Read MoreCustomized resin flow mesh products save time, cost for wind turbine blade manufacturers

As longer composite wind blades are developed, customized mesh products help OEMs and kitting companies control resin flow and remove air voids during infusion.

Read MoreOrbital Composites installs robotic manufacturing system at NREL for wind turbine blade research

Customized, automated platform expands NREL’s capabilities for researching blade-finishing technologies and serves as Orbital’s sounding board for applicable composites solutions in aerospace, space and infrastructure.

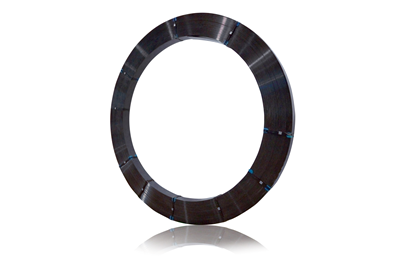

Read MoreHexcel partners with Metyx for high-performance carbon fiber pultrusion technology

Combined expertise within the composites industry will contribute to the manufacture of profiles made from polyurethane resin and UD carbon fiber for the wind energy market.

Read MoreThe outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

Read MoreRe-Wind Network releases repurposed blade design catalog

Re:Wind Design fall catalog presents designs and details of structures and products developed from EOL wind blades, as well as the research team’s services for those interested in repurposing their own.

Read MoreLM Wind Power reports it will produce zero waste blades by 2030

Blade manufacturing waste prevention and recycling becomes the GE Renewable Energy business’ primary focus as it seeks to reduce its carbon footprint.

Read MoreJoule Challenge project launch uses composites for next-generation wind turbine development

Two-part project is to produce a 20-MW demonstration turbine, capitalizing on the U.K.’s large composite component expertise and support the ambition for lower cost manufacturing.

Read MoreNexam Chemical, the NCC develop solution for manufacturing high-temperature composites

Nexam Chemical’s Neximid high-temperature resin system can operate at temperatures up to 400°C, expanding the boundaries of composites into more demanding applications that weren’t previously possible.

Watch

.jpg;maxWidth=300;quality=90)