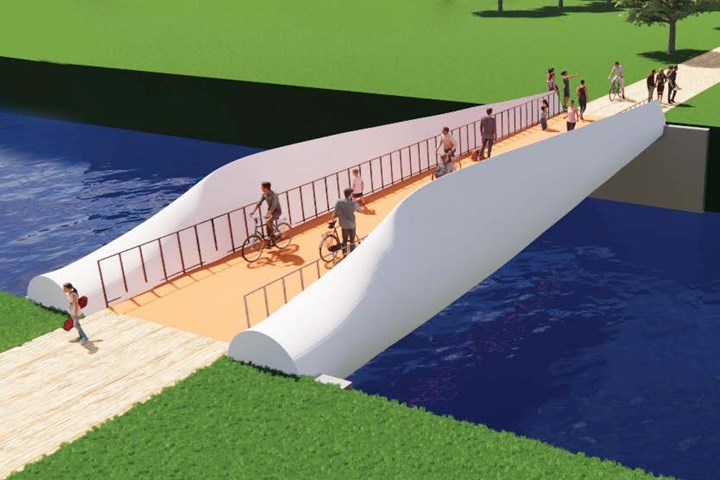

Re-Wind Network releases repurposed blade design catalog

Re:Wind Design fall catalog presents designs and details of structures and products developed from EOL wind blades, as well as the research team’s services for those interested in repurposing their own.

Photo Credit: Re-Wind Network

Re-Wind Network, is an interdisciplinary research team comprising experts from City University of New York, Munster Technological University, Georgia Institute of Technology, Queen’s University Belfast and University College Cork, as well as industry affiliates driving innovation in repurposing wind blades. The group has recently announced the release of their fall 2021 catalog, Re:Wind Design, which presents designs and details of structures and products made from end-of-life (EOL), repurposed wind turbine blades that are available from the Re-Wind Network.

Models of the blades used in the designs were produced at the Georgia Institute of Technology using in-house software from LiDAR scans or documentation of four decommissioned wind turbine blades. Graphics were produced in Rhinoceros 3D (Robert McNeel & Associates, Seattle, Wash., U.S.) and Enscape (Karlsruhe, Germany) software. Blades used in the designs include:

- Nordex (Hamburg, Germany) N29 250-kilowatt (kW) turbine — 13.4-meter blade

- Vestas (Aarhus, Denmark) V44 600-kW turbine — 21-meter blade

- General Electric (Boston, Mass., U.S.) GE 1.5-77 1.5-megawatt (MW) turbine — 37-meter blade

- Liberty Clipper C96 2.5-MW turbine — 46.7-meter blade

According to the Re-Wind Network, each blade represents typical sizes and lengths of blades currently coming out of service globally. Designs detailed in the catalog include BladeBridges, multi-girder bridges, low-profile bridges, cable-supported bridges, BladeBoardwalks, BladePoles, BladeBarriers, BladeShelters and BladeFarming.

Per this catalog, the Re-Wind Network team also offers its services in architectural design, structural engineering analysis and design, and construction management and logistics services to those wishing to repurpose their EOL wind turbine blades, including:

- Develop architectural concepts and designs for potential repurposed structures.

- Construct an exterior surface model of the blade in Rhinoceros 3D from LiDAR point clouds or manufacturer documentation of the blade.

- Construct a “thick” engineering analysis model of the blade from internal point clouds, physical measurements and in-house algorithms.

- Conduct selected testing of materials extracted from the blade to provide the physical and mechanical property data for a blade.

- Provide finite element analysis (FEA) models for 2D and 3D analysis of the entire blade or parts of the blade for use in third-party finite element method (FEM) codes.

- Provide engineering section properties (EI, EA, GJ, kAG) of the blade at selected locations for use in third-party structural engineering codes.

- Conduct structural and stress analysis of the repurposed structures made from the blade including all connections and attachments.

- Perform full-scale testing of prototypes of the repurposed structures made from the blade.

- Perform site investigations and recommend foundations and support structures for the repurposed structures.

- Provide construction cost-estimates, life cycle costs (LCC) and life cycle assessments (LCA) of the repurposed structures made from the blade.

- Provide on-site construction management during construction of the repurposed structures.

The catalog can be downloaded here.

Related Content

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.