Wind/Energy

Arkema strengthens strategic partnership with Continuous Composites investment

The contribution of Continuous Composites’ continuous fiber 3D printing technology will accelerate the innovation of 3D composite manufacturing solutions.

Read MoreUMaine develops collaborative floating offshore wind demo project

The floating offshore wind demonstration project will reduce Maine’s overdependence on imported fossil fuels, produce more than $150 million in total economic output and create hundreds of jobs.

Read MoreGurit supports Indian Wind Energy industry with major investments

The company is investing more than 20 million CHF to set up a core material kitting factory and production site for blade molds, core material extrusion operation and more.

Read MoreGE, COBOD, LafargeHolcim enable taller wind turbines with 3D-printed concrete base

3D-printed bases can be printed on-site and will enable production of wind turbines up to 200 meters in height.

Read MoreDNV GL issues provisional type certificate for GE Haliade-X

Selected as the preferred wind turbine for 4.8 GW projects in the U.S. and U.K., the Haliade-X is considered the most powerful in operation to date.

Read MoreVestas wins 50 MW order for largest Vietnam intertidal wind project

Vestas is supplying and supervising installation of 13 wind turbines made of composites, with the third quarter of 2021 the expected completion date.

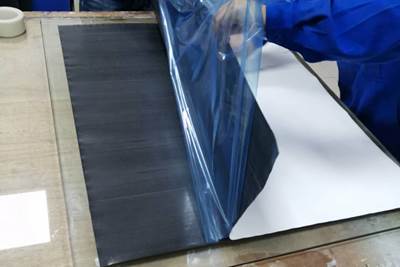

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

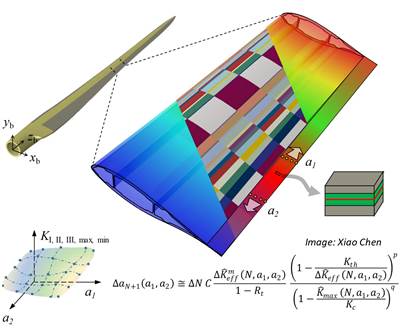

Read MoreFASTIGUE: Empowering digital twins of large-scale composite structures

A 3D finite element technique to resolve the fidelity-versus-speed dilemma of performing fatigue analysis for large composite structures.

Read MoreThicker, carbon fiber-reinforced battery electrodes may enable high-density batteries

University of Delaware research demonstrates use of carbon fiber membranes to enhance conductivity and areal capacity using a scalable manufacturing process.

Read MoreTech Table: Mold release agents

A table of mold release agents collected from data provided by suppliers.

Read More

.jpg;maxWidth=300;quality=90)