Workforce Development

UK composites structure manufacturer continues to expand

Norco, which built its reputation as a manufacturer of large glass fiber reinforced structures, continues to grow and currently offers a wide range of bespoke composite products.

Read MoreArtemis Technologies and Creative Composites partner on eFoiler to cut drag on fast vessels by 90%

Composites-intensive electric propulsion system will make marine travel at high-speed and long-range commercially viable and help meet U.K.’s 2025 zero-emissions requirements.

WatchAutomation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

Read MorePeople in Composites: February 2020

Solvay, SGL Carbon, Teijin, Gurit, Composites UK and American Colors Inc. announce new hires and retirements in the composites industry.

Read MoreInstitute for Plastics Processing at RWTH Aachen University to build "Smart Factory"

The Plastics Innovation Centre 4.0 is expected to open by 2022, and will be a completely interconnected, 4,205-square-meter R&D environment.

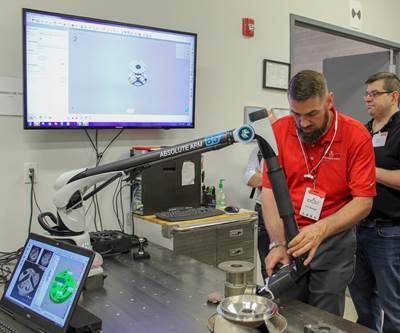

Read MoreExact Metrology to open new center in Moline, Illinois

The new training, support, contract measurement and sales facility will open March 1.

Read MoreEnabling a circular economy approach to advanced composites innovation, manufacturing and use, Part 2

IACMI chief technology officer Uday Vaidya reflects on IACMI’s role in improving composites’ recyclability and reusability.

Read MoreEpisode 31: John Riendeau, Rhode Island Commerce

Rhode Island Commerce director of business development John Riendeau discusses how the state’s legacy experience in boat building has translated into expertise in new markets within the composites industry.

ListenSTELIA Aerospace participates in AILE project with Bombardier

STELIA Aéronautique Canada’s R&T teams will lead the project to build a thermoplastic composite trailing edge flap as a testbed for Bombardier.

WatchConbility tape placement head installed at University of Limerick

The PrePro 3D system combines laser-assisted thermoplastic tape placement with IR-assisted thermoset prepreg placement.

Read More