Workforce Development

Laboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read MoreUniversity of Auckland, DLR researchers cooperate in space research

New Zealand and German space experts are partnering up for research into using carbon fiber for spacecraft and laser light technology to transmit data to Earth.

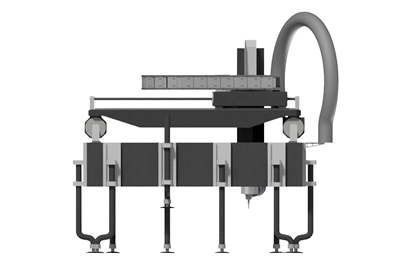

Read MoreLifting arm concept and automated repair training to propel portable repair system

Looking to commercialize its Portable Scarfing/Composite Repair System concept, AGFM and partners offer specialized training, lifting and inspection systems.

Read MoreTRB Lightweight Structures contributes composite bodyshell design to passenger train demonstrator

The Revolution VLR (Very Light Rail) passenger vehicle serves to simplify existing rail networks and reopen historical lines, while adhering to rigorous rail and sustainability regulations.

Read MorePultruded fiberglass rods enhance athletic training device

Jump Sticks, developed by Flexi-StiX LLC, combine pultruded fiberglass rods within a PVC tube to produce a semi-flexible but resistant training device for enhanced dynamic athletic training.

Read MoreFACC seeks 200 new hires in IT, digitalization, innovation and automation

Upswing in aviation, including 2021 new contracts worth €1 billion, impels FACC investment of €150 million to support short-cycle processing of lightweight composites, recycling and expanded production via automation and next-gen manufacturing technologies.

Read MoreNC State University study kick-starts carbon fiber production process

Addition of chemical additives, glucaric acid and mucic acid, into precursor PAN material decreased energy requirements for conversion into carbon fiber five-fold.

Read MoreClogging the brain drain: Growing the composites workforce in a pandemic era

As Baby Boomers retire and high school and college graduates forestall their entry into the workforce, composites fabricators need to get creative to close the gap.

Read MoreAirbus seeks 6,000 new hires in first part of 2022

Worldwide search focuses on new skills to support long-term projects and ambition, notably in the fields of decarbonization, digital transformation and cyber technology, with one-third of recruitment allotted to new graduates.

Read MoreUniversity of Iceland develops process for manufacturing one-piece racecar airfoils

Called the “Spark” method and based on a method for producing CFRP prosthetics, this single-mold, adhesive-free process is said to show potential for a variety of applications.

Read More