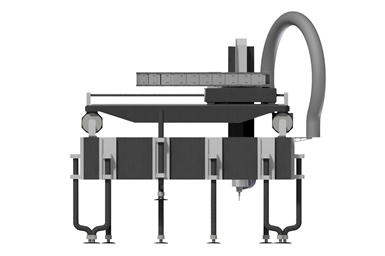

GFM’s Portable Scarfing/Composite Repair System (PS/CRS) concept aims to enable portable, digitized inspection, scarfing and repair of large composite structures such as aircraft wings. New partnerships aim to offer customers a full range of training, transport and inspection options. Photo Credit: AGFM

American GFM (AGFM, Chesapeake, Va., U.S.), the U.S. branch of Austrian machine tool and composites manufacturing systems supplier GFM, has been developing automated and portable repair technology for composite aircraft and other parts since 2006. The newest iteration, called the Portable Scarfing/Composite Repair System (PS/CRS), will be powered by software from Wichita State University’s (WSU) National Institute for Aviation Research (NIAR, Kan., U.S.) to create a digital thread of repair data for a part and to use 3D scan data to inform the fabrication of a repair patch (for background and more on PS/CRS technology, see “Moving toward portable, digitized composite part repair”).

According to Frank Elliott, advanced initiatives coordinator at AGFM, the next step will be to move the PS/CRS from the prototype stage to customer use. In response to conversations with potential customers, AGFM has recently formed several partnerships to offer professional training on the PS/CRS system, and equipment for lifting the system onto an aircraft surface and supporting its weight during scarfing and repair.

Specialized composites repair training

Abaris Training Resources offers classes in traditional field repair processes for composite parts as well as a new course for training on AGFM’s automated system. Photo Credit: Abaris Training Resources

To help ensure companies are equipped to operate the PS/CRS system, AGFM has partnered with Abaris Training Resources (Reno, Nev., U.S.) to offer training on composite repair processes. This training will include general training on the basics of composite repair — scarfing, repair patches, manual field repair methods, techniques and repair via hot bonders, heat blankets or other heat sources — in addition to a new course offered covering AGFM’s automated processes.

Custom lift arm concept

The PS/CRS comprises a 5.4-foot x 5.4-foot x 4.75-foot frame that includes vacuum pods, a milling system with attached spindle unit, an electronic and CNC box, a vacuum dust extraction system and an optional non-destructive inspection (NDI) and/or scanning system. The overall system is intended to be portable — transportable to a field site for on-site scarfing and inspection, even on the wing of an aircraft itself.

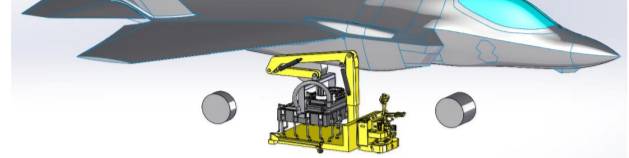

This concept lifting arm system is designed to lift and support the PS/CRS directly onto an aircraft or other structure. Photo Credit: Field International Group

To make this possible, AGFM has partnered with global ground support equipment (GSE) supplier Field International Group (Poole, U.K.) to create a specialized lifting arm system for transporting the PS/CRS onto an aircraft or other structure. The lift system will elevate the 320-pound PS/CRS frame to its proper location on an aircraft or other structure, and attach it to the part surface with vacuum pods.

The road-transportable concept involves a roughly 11-foot x 6-foot x 8-foot system consisting of a platform for holding the PS/CRS and a double boom with telescopic mast for lifting the PS/CRS on top of an airplane wing or fuselage, or to lift and support the PS/CRS upside-down underneath the wing for the duration of a repair.

Laser-based inspection and automated 3D scanning

In addition, AGFM has partnered with two suppliers to enhance its scarfing system with inspection and 3D scanning capabilities.

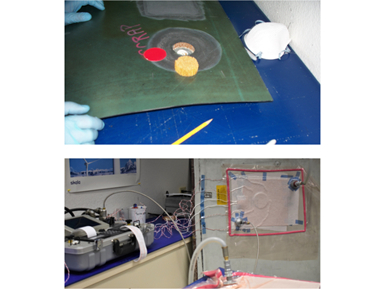

Aligned Vision (Chelmsford, Mass., U.S.) will offer its LASERVISION laser-based system, which is capable of automatic, in-situ inspection, verification and documentation of fiber orientation, foreign object debris (FOD) and material location, as well as projected layup guidance for composite repair. Elliott notes that the data collected by this system will feed into NIAR’s digital thread software.

LASERVISION can be run as a standalone system or integrated with the repair cell computer via PLC interface or through software development kit (SDK) integration.

Aligned Vision’s LASERVISION (pictured left) works with the PS/CRS for laser-based inspection and repair patch alignment. Zeiss’ T-Scan Hawk (right) provides 3D scanning for inspection or repair patch development. Photo Credit: Aligned Vision, Zeiss

In addition, Carl Zeiss Industrial Metrology LLC (Wixom, Mich., U.S.) will offer its T-Scan Hawk industrial 3D scanner to digitize the damaged surface area. The handheld manual laser scanner will be used by the operator on the work platform while the PS/CRS is being lifted and moved into place and attached to hte aircraft for repair. The T-Scan Hawk is said to enable fast, objective measurement on difficult part surfaces for either inspection or development of tooling or a repair patch. Elliott notes that AGFM has used Aligned Vision and Zeiss products successfully in its previous repair projects.

For more information, contact Frank Elliott at elliott@agfm.com or Jeswin Joseph, program and research manager at NIAR/WSU, at JeswinJoseph@niar.wichita.edu.

Related Content

Toray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

Read MoreDetermining steel/composite failure load of bonded repair assemblies

Bureau Veritas and partners use a novel equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structures.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreRefurbished Einstein yacht demonstrates innovative composites repair and redesign

Years of creative engineering work went into resurrecting the composites-intensive IMOCA 60 racing yacht — with award-winning results.

Read MoreRead Next

Moving toward portable, digitized composite part repair

Using digital twin technology, American GFM’s portable, automated inspection and scarfing system shows potential for on-site, data-driven composite aircraft part repair.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)