According to the World Health Organization and other groups monitoring amputation and limb loss, 60-100 million people worldwide need a prosthetic limb. This population is expected to double by 2050, driven primarily by the growth in diabetes and vascular disease. Depending on the country and age group, at least 70% of those needing prostheses involve lower limbs, yet only 5-15% of amputees have access to a prosthesis.

“The majority of people with lower limb amputations don’t have access to high-quality fiber-reinforced composite foot prostheses due to their high cost resulting from complex, manual manufacturing processes,” explains Daniel Kun, managing director and CTO of steptics (Munich, Germany). “The cost for these foot prostheses can be $5,000 or more. If you don’t have good insurance, then you can’t afford these. Even in Germany, it’s not possible for most people to pay for these out of pocket.”

Most carbon fiber-reinforced polymer (CFRP) foot prostheses are made by hand laminating numerous prepreg layers into a tool and then curing in an autoclave, followed by trimming and milling. “These kinds of manual procedures are super expensive,” notes Kun. “My background is in automotive, developing automation to reduce the cost of CFRP components. I wanted to transfer this approach to prostheses and use the cost savings to make them more accessible. Steptics was founded based on an innovative, automated and patented manufacturing process that cuts manufacturing costs by 50%. What drove me was the idea to make a difference, that by industrializing production, I could really change the performance and price point on CFRP prostheses.”

Automotive background and CFRP

“I’m basically a skilled toolmaker,” says Kun. After earning an automotive engineering degree and then a master’s degree in systems engineering and management, Kun began his career at Voith Composites (Munich, Germany). “I was part of the program to industrialize all the different stages for the production of CFRP automotive parts. Automating the press molding and machining processes for the Audi A8 rear wall/seat back program was pretty much what I had to do in 2009. This was due to my background as a toolmaker, but I also had 8 years of experience with Formula Student racing teams.”

The story of steptics began with Kun walking to work every day. “I would pass a company with a typical carbon fiber composite wheelchair in the window and wonder why they made them using the same old methods. One day, I went into the shop and asked to speak to the person responsible for that wheelchair. That started a collaboration with Voith Composites to design more optimized wheelchairs and foot prostheses. And with that project, I had the idea for my patent. When I decided to leave Voith Composites, I was able to buy the patent out of the company, and that’s how we were able to found steptics.”

But why do foot prostheses have to be CFRP? “Continuous fiber-reinforced composites are the only materials that guarantee both light weight and high energy return for the high performance and fatigue resistance needed [for these applications],” says Kun. “It’s all about the energy return. There are prostheses made out of metal and unreinforced plastics, but most patients don’t like these because they are heavy and lower performance. They don’t return the energy as well, so it makes it harder to develop a normal gait. It’s like walking in sand. But if you had a lower limb amputated, wouldn’t you want to get the best performance in a prosthesis to try to achieve your former mobility?”

Indeed, loss of mobility for lower limb amputees often leads to health issues, as well as loss of independence, social withdrawal and increased risk of depression. “Our goal is to really restore and maximize mobility, including high levels of exercise and sports,” says Kun. “But, as I explained before, the processes behind high-performance prostheses are manual and not scalable, thus these products are unaffordable for the majority of the people who need them.”

Materials and process

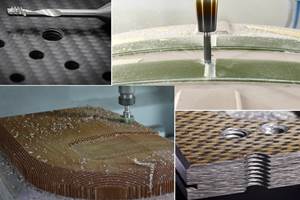

Steptics uses filament winding to create a large, shaped tube (top) which it cuts into slices (bottom left) and then cuts the slices into halves (bottom right).

Steptics brings automation to the prosthetic world via the filament winding process. “We first build a mandrel which has the inner geometry of the prostheses,” says Kun. “The fiber is pulled through epoxy resin and then wound onto the rotating mandrel. The resin is typically used for vacuum infusion processes in the aircraft industry, and we use T700 type carbon fiber from Toray [Tokyo, Japan], although we could also use glass fiber or basalt or other fibers. T700 has good properties that are very well known, and it is well proven in filament winding.”

“We filament wind a long, shaped tube that we then cure in an oven,” he continues. “It’s pretty much the same curing process as with filament-wound pressure vessels. We then we cut the long tube into slices, and cut the slices into halves to get semi-finished parts. These are then individually machined to tailor the geometry and performance to the individual amputee.”

AI-assisted customization

One reason prostheses have been challenging to industrialize is the need to customize each product for the individual amputee. “That’s true,” says Kun. “We need to know the amputee’s weight and whether a left or right foot prosthesis is needed. We also want to know what they want to do with the prosthesis. Are they a walker or a jogger? And that defines the spring characteristics needed in the final prosthesis.”

Steptics has developed AI that calculates the optimal geometry based on the amputee’s individual parameters, which then guides automated machining of the 3D CFRP blanks.

“We solve the problem of an individual product through a two-phase industrial-scaled process,” explains Kun. “In the first phase, we define the base material properties needed and use automated filament winding to consistently manufacture high-quality 3D shaped blanks. In the second phase, we have developed AI that calculates the optimal geometry for the prosthesis based on the individual’s parameters, such as the stiffness and energy transfer needed. The 3D blank is then cut and milled to deliver that performance.”

The latter phase was developed in partnership with composites machining specialist Hufschmied (Bobingen, Germany, see “Optimizing machining for composites…”). However, conventional filament winding limits possible geometries to fairly simple curves, notes Kun. “So, we developed a second major manufacturing process that is similar, but allows us to form the blanks to any geometry, for example wave-like shapes or an ‘S.’ We can now build every thinkable geometry for a prosthesis.”

Initial products and production

For the first process, says Kun, “we have the first production line, and have made a proof-of-concept prosthesis and tested it according to ISO 10328. It performed well and withstood 2 million cycles of loading without any degradation. This first product will be a CFRP blade or sole that is a sports prosthesis, amputation level 270.”

Kun explains that amputation level refers to the height of the leg amputation from the ground. “It defines the minimum installation height required for the prosthesis.”

“Our target is to go to market in summer 2024,” says Kuns. “We are starting with these running blades because they must perform better than everyday prostheses, so we can really address that. But also, it’s challenging for amputees to resume physical activity, compounded by the fact that such prostheses typically aren’t covered by health insurance. Our goal is to offer these high-performance sports prostheses at an affordable cost.”

He explains that typical state-of-the-art hand layup produces 1-2 prostheses per day. “But with our manufacturing process, with a mandrel 10-12 meters long, for example, we’re able to build 250-500 prostheses per day. That’s a significant difference and means we can save roughly 50% of the cost.”

Kun explains that steptics will pursue both a business to business (B2B) and business to consumer (B2C) model. “We are collaborating with established prosthesis manufacturers, our B2B customers, in white label projects where they can sell our products through their distributor and sales pipeline worldwide. Concurrently, we are developing and distributing our own models directly to consumers. For example, we want to sell the sports prostheses, including our initial running blade, via our homepage worldwide. And eventually, we want to establish subsidiaries in the U.S., India and China with our own employees, to further develop and sell products in those markets.”

As far as product differentiation, there are products focused on higher performance with a slightly higher price and those targeting the large amputee population in developing countries where the lowest price is necessary, demanding a simple design but still made out of continuous fiber-reinforced composites. “So, we are aiming to launch the sport prostheses in summer, the simpler export prostheses in fall to winter of 2024 and then a third product made using the second production process for more complex, tailored geometries. We are actually working now to produce this under white label for a customer’s brand.” This manifold approach is designed to help steptics meet its financial goals as well as its commitment to make prostheses more accessible worldwide.

Challenges, future development and sustainability

In addition to the challenge of automating production and meeting customized performance needs while lowering cost, these prostheses must meet strict medical requirements and certifications. The latter has been referred to by some in the medical market as more difficult than aircraft certification. “This means it’s super difficult to switch materials, for example, because you would have to requalify the whole product and it’s very time-consuming and expensive to qualify those kinds of products,” notes Kun. Even so, steptics is looking toward making its products more sustainable.

“Our first steps were to reduce costs through automated production and development of AI for individual customization,” says Kun. “Now, we want to tackle the issue of sustainable materials. Unfortunately, carbon or glass fiber do not have the best CO2 footprint. However, many natural fibers don’t have the strength and stiffness to withstand the predominant loads. Thus, by themselves, they aren’t yet suitable for running blades or even everyday prostheses. We are still researching what reinforcements could work.”

However, the company is committed to developing improved materials and sustainability. “This is important because we should have sustainable materials in the prosthetics industry,” he adds. “We are working on a project through a German government program and aiming to have, in 2-3 years, results where we can move forward with new fibers and resins. And then we have to complete qualification.”

“For now,” says Kun, “We are testing our products with amputees and getting certified as a medical devices manufacturer. This all takes time, but we expect to have the first product ready for the market soon. Preliminary tests have already shown that our running blades exhibit very good performance.”

“In the coming years,” he continues, “steptics will further improve our prostheses and develop new products. We will improve sustainability and also availability of our prostheses in the Global South, where there is significant demand but insufficient purchasing power. Our aim is to use our automated and efficient processes to provide suitable solutions that empower and increase quality of life for amputees and ensure accessibility to everyone who needs them.”

Related Content

Belotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Read MoreRead Next

CFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreNew 3D-printed prosthetic leg features carbon fiber definitive socket

Additive manufactured thermoplastic carbon fiber definitive prosthetic socket allows for life cycle adjustments without weakening its structure

Read MoreLighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

Read More