Composites Cutting/Kitting

Kitting and cutting are crucial processes in composite manufacturing, involving the precise preparation and shaping of materials before their assembly into final composite structures. Kitting involves organizing and preparing the composite materials—such as fibers, fabrics, or pre-impregnated sheets—according to specific designs or patterns. Precision cutting then follows, utilizing specialized machinery or tools to accurately shape these materials based on predetermined templates or CAD designs.

Latest Cutting/Kitting Articles

VIEW ALLZünd, Loop Technology partner on FibreLine preforming system

Pairing Loop Technology’s automation with Zünd digital cutters provides faster cutting, less stray fibers, higher ply accuracy and more precise preforms for composite aerostructure manufacturing.

Read MoreNorco invests in CNC, kit cutting capability expansion

Transition from internal to external demand over the last few years has evolved Norco’s machining and composite kit cutting equipment, and now includes material outsourcing and digital engineering services.

Read MoreRe:Build launches line of thermoplastic composite slitting, ply stacking equipment

TPX line of tape slitters and off-axis, continuous roll ply stacking equipment is customizable to bring thermoplastics part production up to scale.

Read MoreComputer-controlled conveyor system improves precision in cutting operations

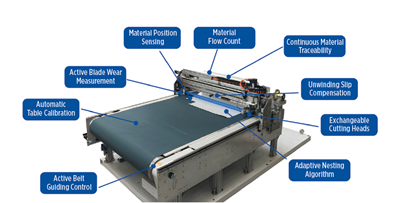

CAMX 2024: Eastman Machine Co. showcases the Eagle C135, a computer-controlled conveyor and cutting system designed to cut a range of technical and industrial fabrics and composites.

Read MoreCold cutting equipment designed for carbon fiber

CAMX 2024: Sheffield, a producer of highly accurate cutting machines, highlights its C-503 model machine made to cut carbon fiber, fiberglass and even natural fibers.

Read MoreCutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

Read MoreKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORE

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORELatest Cutting/Kitting News And Updates

Composite cutting systems are dedicated to material optimization

CAMX 2024: FKgroup showcases its solutions for cutting composite materials, focusing on sustainability and efficiency.

Read MorePrecision sheeters, slitter rewinders are customizable to material needs

CAMX 2024: Pasquato exhibits its high-speed precision sheeters and slitter rewinders to enhance flexibility and material cutting quality.

Read MorePly stacking, cutting process optimized via automation, smaller footprint

CAMX 2024: Schmidt & Heinzmann customers are able to produce SMC or dry fiber fabric stacks more efficiently thanks to the AutoCut Pick&Place system.

Read MorePrecision blades support industrial fiber cutting needs

CAMX 2024: Machine knives and industrial razor blades supplier American Cutting Edge offers composites manufacturers staple and custom cutting options.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreOptimized, automated manufacturing concepts for composite parts, SMC semi-finished materials

JEC World 2024: The AutoCut Pick&Place and Cube SMC line from Schmidt & Heinzmann aim to deliver more modernized manufacturing capabilities with improved efficiency and process control.

Read MoreFeatured Posts

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

WatchPlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreImprove production with five-axis machines built for composites

Virtually tour (4) USA-Made 5-Axis CNC Machines designed and engineered to help companies improve profits by decreasing cycle times and improving part quality. (Sponsored)

WatchPlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read MoreModular cutting and stacking system advances flexible, fully automated operations

Integration of next-gen cutting and stacking systems into production lines brings new level of efficiency, quality control.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read More

.jpg;maxWidth=300;quality=90)