JEC Europe 2013 review

Snow in Paris slowed traffic to the show floor but did nothing to cool the enthusiasm of composites innovators in a broad range of markets.

When the JEC Europe 2013 trade show got underway at the Paris Expo (Porte de Versailles, Paris, France), it was the biggest ever, in terms of exhibition space. A rare Parisian snowstorm on the first day put a damper on attendance, but the event attracted composites manufacturing professionals from around the world who presented, or sought, the latest in composites technology, innovation and information. As always, CT’s editorial crew was on hand and returned with an abundance of news, distilled here in short form. (CT staffers also collected a wealth of new product news. You’ll find a large sampling of exhibitors’ technologically innovative wares in the “JEC Europe 2013 Product Showcase,” under "Editor's Picks," at top right.)

On the show floor

Among the JEC Europe 2013 Innovation Award winners were Arkema Inc. (Colombes, France) and partners PPE (Pole de Plasturgie de L'Est, Saint-Avold, France), 3B – the fibreglass company (Battice, Belgium) and MVC (São José dos Pinhais, Brazil), who were recognized for the first new thermoplastic resin that enables the manufacture of composite parts on the same equipment and with the same processes used to form thermoset composites.

Several other exhibitors addressed similar efforts in presentations made at JEC’s Sustainability conference. DSM Composite Resins (Schaffhausen, Switzerland, and Zwolle, The Netherlands) was included, with a focus on cobalt-free curing solutions for preaccelerating resins, as was CCP Composites (Courbervoie, France, and Kansas City, Mo.), with a focus on styrene-free unsaturated polyester resins. Pergan GmbH (Bocholt, Germany) premiered its new line of Pergaquick CP accelerators based on a reportedly nonhazardous, nontoxic cobalt polymer.

Hexagon Composites ASA (Ålesund, Norway) announced a rebranding effort that has gathered all its business units under the Hexagon name. Three are in Norway: Ragasco AS and Raufoss Fuel Systems AS (both in Raufoss) and Devold AMT (in Langevåg). A fourth is in the U.S.: Lincoln Composites (Lincoln, Neb.). Each business unit now bears a common identity and will be referred to, respectively, as Hexagon Ragasco AS (LPG cylinders), Hexagon Raufoss AS (high-pressure cylinders), Hexagon Devold AS (multiaxial fabrics and reinforcements) and Hexagon Lincoln Inc. (high-pressure cylinders). The company says that after 14 years of solid project and product portfolio growth, the unified global identity is expected to foster international expansion. In one example of that growth, Hexagon Raufoss was recently awarded a contract from a U.S. automotive OEM for the serial supply of CNG high-pressure composite cylinders to serve as fuel tanks for a model that will run on natural gas. The value of the contract is NOK 90 million ($15.36 million) over a four-year period.

Momentive Specialty Chemicals Inc.’s (Columbus, Ohio) president, Joseph Bevilaqua, spoke with CT about his company’s growth and expansion. He reported that 2012 was a record year for Momentive in the wind energy sector and cited “numerous projects” in the automotive sector that have resulted from the aggressive mileage goals for new cars. The company’s new products included EPIKURE 05500 fast-cure epoxy with EPIKOTE binder 04695-1/EPIKURE 05490A curing agent for Class A parts via gap impregnation RTM.

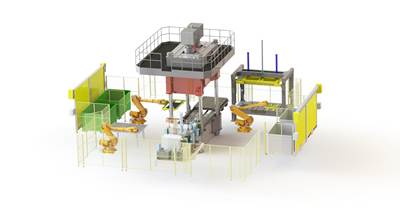

Innovation Award winner: BMW i3

In 2012, automotive composites and their applications took center stage. They did so again this year in an even bigger way. This was especially evident in the JEC Europe 2013 Innovation Awards display on the show floor, where the main attraction was the award-winning carbon fiber passenger cell designed and built by BMW Group (Munich, Germany) for its forthcoming all-electric commuter car, the BMW i3. Formed with carbon fiber produced in the U.S. by SGL Group (Wiesbaden, Germany), the i3 cell was first exhibited at JEC two years ago, but the 2013 version, which features BMW wheels and an aluminum undercarriage that will hold batteries for the i3, more closely approximates the finished product. The i3 is due on the market later this year and is the first production vehicle to use carbon fiber in the passenger cell. The cell is an all-carbon fiber composite and, apparently, it is molded in sections that are bonded together. On the question of whether the i3 body panels will be carbon composites, there is no official word, but injection molding machine maker ENGEL AUSTRIA GmbH (Schwertberg, Austria) reports that it has sold two large machines to BMW for use in its Leipzig, Germany, facility “to manufacture lightweight components for car body shells.” Although ENGEL didn’t identify which car, the CT staff believes the tea leaves read pretty clearly: the Leipzig plant is the site for primary assembly of the i3, so it is unlikely that the i3 body panels will be metal. (See Fig. 1.)

Seeking optimal solutions in thermoplastic composites for automotive mass production, Owens Corning Composite Solutions Business (Toledo, Ohio) announced a strategic alliance with BASF SE (Ludwigshafen, Germany) and TenCate Advanced Composites (Nijverdal, The Netherlands, and Benicia, Calif.). According to Owens Corning group president Arnaud Genis, “There is a critical and growing need in the automotive industry to have lighter, stronger and more environmentally efficient products.” In an onsite interview with CT, Genis affirmed that the composite materials market is growing faster than other materials markets, and with a rebound of the housing market (roofing shingles) and wind power, his company is situated to grow and meet glass fiber demand. In his view, the next big market for composites is automotive, and he said that OEMs are now more willing to pay to take weight out of automobiles to meet aggressive mileage goals. “We are at the tipping point of generating new applications for composites,” he noted. To that end, Genis and two colleagues — Dr. Martin Jung, head of structural materials research at BASF Research; and Dave Clark, TenCate’s global group director — announced a strategic alliance to develop optimal solutions in thermoplastic composites for automotive mass production during a press conference at the show. Although they did not announce specific products, Owens Corning pledged its expertise in developing “tailor-made” fabrics and other reinforcements that are compatible with thermoplastics. BASF will contribute comprehensive knowledge in the production and formulation of thermoplastic resins, and TenCate will contribute its expertise in composites manufacturing.

3A Composites (Sins, Switzerland) and Dow Chemical Co. (Midland, Mich.) announced a strategic cooperation to market innovative core material solutions to the wind energy industry. The effort will focus on a new thermoplastic polystyrene (PS) foam product on which Dow had recently begun work. Dow will partner with 3A to finish product development and bring it to market. Dow said initial testing shows that a PS core has better mechanical properties than a polyvinyl chloride (PVC) core, which is a standard in wind blade manufacturing. Although its market debut is uncertain, Dow and 3A officials at the show said they are targeting a 12- to 18-month time frame.

Resin manufacturer Reichhold LLC2 (Durham, N.C.) highlighted its sustainability efforts for the composites market, which includes its participation in primary industry associations to expand the market for composites through innovative technologies, reduce the eco-footprint of composites and define safe conditions for composites manufacturing. Its R&D innovations are aimed at recyclable resins for all composites manufacturing processes. Those for pipe manufacturing, for example, have been shown to provide 12 percent lower CO2 emissions than standard alternatives. Further, renewable resins that eliminate hazardous materials, such as water-emulsified Beckosol AQ alkyd latex resins, are said to offer superior performance over conventional solvent-borne systems. The development of low-VOC, styrene-free and monomer-free resins for advanced applications and safe-to-use resin curing systems are targeted. The company cites its participation in the RenWind Project, sponsored by the Research Council of Norway (Oslo), where it aims to develop environmentally friendly and cost-efficient, high-performance, styrene-free vinyl ester resins for production of wind turbine blades.

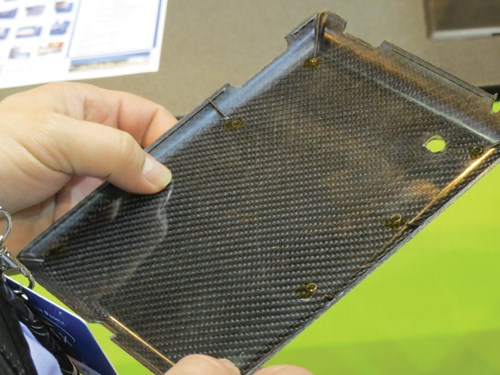

Inductively heated tooling

Molded carbon fiber/thermoplastic covers for tablet devices from Roctool Inc. (Le Bourget du Lac, France), which are made with the company’s 3iTech compression molding technology, were also featured in the Innovation Awards display. The technology uses inductor coils to provide fast heating of the tool cavity and produces parts in relatively fast cycle times. See Fig. 2.)

JEC Europe 2013 marked the first time TenCate Advanced Composites (Morgan Hill, Calif.) exhibited at a show since it acquired Amber Composites (Langley Mill, Nottingham, U.K.) in January of this year. The acquisition gives TenCate thermoset manufacturing capabilities in Europe. In addition, Amber has an established line of tooling prepregs and is active in Formula 1 racing and other automotive applications. The show also marked the first full year since TenCate acquired Performance Materials Corp./Baycomp (Burlington, Ontario, Canada). The focus for the acquired companies is performance composites for the electronics, automotive and oil and gas industries, primarily with thermoplastics, but also with TenCate thermosets.

Polyurethane + RTM

Prominent at the show was a variety of glass fiber composite leaf springs for use in car and truck suspension systems. One example, featured at the SGL stand, was developed by Henkel AG & Co. KGaA (Düsseldorf, Germany) and molded by Benteler SGL Carbon SE (Ried im Innkreis, Austria) with a specially developed resin transfer molding (RTM) process. Compared to conventional leaf springs made of steel, the composite springs are as much as 65 percent lighter. The resin, Henkel’s Loctite MAX 2, a polyurethane-based formula, is said to cure significantly faster than the epoxy products that are usually employed in the RTM process. Due to its low viscosity, the polyurethane reportedly penetrates and impregnates the fiber reinforcement more easily and with less fiber displacement, thus enabling very short injection times. Henkel says Loctite MAX 2 has an exceptionally high stress-intensity factor, which is a measure of toughness. This characteristic, says Henkel, has a positive effect on the fatigue behavior under load. Leaf springs in cars are constantly subjected to dynamic loading under driving conditions, so the use of flexible materials with a high fatigue tolerance prolongs component life. RTM and other resin injection processes predominate in the manufacture of automotive composites for mass-produced automobiles because they make it possible to control the cure reaction more reliably, either by adjusting the temperature or adding an accelerator. (See Fig. 3.)

The United Soybean Board (USB, St. Louis, Mo.) talked up a recent expansion of soybean derivatives into composites manufacturing and the more than 750 products that contain soy. One recent project is soy-based foam used in seats manufactured by Lear Corp. (Southfield, Mich.), made with 5 to 15 percent soy material. Lear’s SoyFoam reduces carbon use, takes less energy to manufacture and has up to 70 percent lower VOCs than petroleum-based foam and, says Lear, it is less sensitive to petroleum cost fluctuations. USB says that soy-based resins for composites processing are available from Ashland, LLC (Dublin, Ohio) and Reichhold Inc.

Commuter car for the city

Another JEC Europe 2013 Innovation Award winner was the VéLV (le Véhicule électrique Léger de Ville) from automaker PSA Peugeot Citroën SA (Paris, France). This urban commuter car features three seats and sports an empty weight of only 700 kg/1,543 lb, 130 kg/286 lb of which is battery. Its per-charge driving range is said to be 100 km/62 miles. The glass fiber/epoxy vinyl ester composite body is a polyurethane-cored sandwich structure joined to an aluminum spaceframe. Although its eight body parts were made for this prototype via resin infusion, the production version reportedly will be resin transfer molded. The builders say the body weighs about 80 kg/176 lb; with carbon fiber reinforcement the body weight could be shaved to 50 kg/110 lb. (See Fig. 4.)

UPM-Kymmene Corporation (Helsinki, Finland) updated attendees on its 2012 introduction of ForMi, a bio-composite composed of 20 to 50 percent cellulose fibers and polypropylene, and reported that the product is now used in several injection molding applications. Among them are Finland-based audio loudspeaker maker Aurelia, where ForMi is used to craft speaker components, and Puustelli Group Oy (Harjavalta, Finland), a kitchen cabinet maker that uses the product to fabricate its “eco-kitchen” cabinet panels. The company reported that it has already secured U.S. Food and Drug Admin. (FDA) food contact certifications and the applicable European Union certifications. (For more on the bio-fibers front, see “Bio-composites update” under "Editor's Picks").

Five pump parts in single E-LFT molding cycle

Weber Fibertech has been involved in auto manufacturing for 35 years and entered the field of fiber-reinforced plastics in 1998. At JEC Europe 2013, with its consortium partners Weber Automotive GmbH and Weber Motor GmbH (all located in Markdorf, Germany), the company showed off the Weber Jet Pump for the Weber MPE 850 Marine boat engine for rigid inflatable boats. The pump features five compression molded parts that replace previous aluminum castings. As a result, the weight of the 155-hp engine is a mere 95 kg/209 lb. The five parts are molded in a single step from glass fiber/polyamide 6 in Weber’s endless long-fiber thermoplastic (E-LFT) process, which enables the use of continuous fiber where long-fiber material isn’t sufficient. The process advantages reportedly include greater freedom to optimize part strength and stiffness, improved corrosion resistance, particularly in saltwater, and reduced tooling and processing cost. (See Fig. 5.)

Zoltek Corporation (St. Louis, Mo.) announced its recent partnership with Thermoplast Composite GmbH (TCG, Langenfeld, Germany) to develop and improve carbon fiber/thermoplastic tapes and other products made with Zoltek industrial-grade fiber via TCG’s innovative process technologies. The products are targeted to structural applications for automotive and other industries, say the two companies. Specifically, the carbon fiber tapes can be used as the primary reinforcement in structural parts or as localized reinforcement for injection molding applications for low-cost, structurally optimized parts, such as seat backs, front-end carriers, bumpers, doors and other automotive components that have complex geometries.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

Read MoreBio-composites update: Beyond eco-branding

No longer dependent only on their green credentials, some suppliers of bio-based fibers and resins are competing on price and performance.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)