“We were building molds using CNC machined polyurethane foam and hand layup GRP (glass fiber-reinforced plastic), but that approach involved too much labor and waste,” explains György Juhász, owner of Rapid Prototyping (Budapest, Hungary), which bought a CEAD Robot Extruder in December. “We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.”

Rapid Prototyping assisted with the development of Como Yachts and Narke, both designed by naval architects Akos Reder and Tamas Reder. SOURCE | Como Yachts.

Juhász began working with composites as a boatbuilder. His projects include Como Yachts and the Narke Electrojet, which claims to be the world’s first all-electric personal watercraft in series production. “In Hungary, you cannot use petroleum-based fuels on any lakes, and we have the second largest lake in Europe,” he explains. “We are developing more electric boat models for companies. I needed a faster, cheaper way to create plugs and molds for these projects.”

The CEAD Robot Extruder was Juhász’ Christmas present last year. “I already had a 5-axis CNC machine,” he says, “so we just bought the Robot Extruder print head and attached it.” The CNC machine measures 4850 by 2635 by 1460 millimeters and uses stepper motors with Mach3 motion controller software. Designed and built by Juhász six years ago, it was available to convert to a 3D printer when he purchased a new Hungarian-built CNC system last year to take over milling and machining.

Rapid Prototype 3D printed the composite mold used to produce a composite shell structure, which will be transformed by its customer, Krismar, into a customized heavy truck sleeper cab. SOURCE | Krismar.

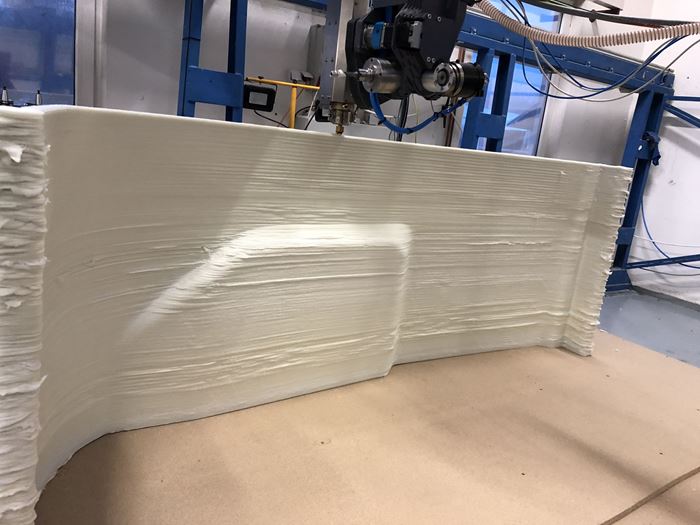

One of the first projects completed with this new 3D printing system is a fiberglass mold for a composite sleeper cab for custom truck and trailer manufacturer Krismar (Waardamme, Belgium). “This is quite a big component, measuring 2550 by 2200 by 1200 millimeters,” says Juhász. “We wanted to print the maximum thickness possible in order to avoid warping and deformation when cooling down.” The 30-millimeter thickness was printed in two layers of 15 millimeters each and used almost 400 kilograms of glass fiber-reinforced polypropylene pellets.

The mold was printed in four pieces, including separate left and right sideskirts. “We CNC milled the molding faces of each piece separately,” he explains, “and then screwed and clamped them together before applying sandable gelcoat and hand-laminating with four layers of 300 grams/square meter chopped strand mat and polyester resin.”

Though the project was successful and 3D printing saved time, Juhász admits there is a lot to learn. “One of the biggest challenges with this approach is after the printing we need to find a 0 point (origin) with the milling machine and software. We do the printing vertically and the milling horizontally — so, the starting point and the direction of each operation is different.” It also seems expensive to print solid instead of using an infill? “For this project, we were at the beginning,” he explains. “An extruder head using pellets is cheaper than a large-format filament printer, but not as easy for printing infill. But we are planning to print a piece of furniture with infill in the future, so we will adapt the lessons learned to our tool making.”

Related Content

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreChantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreRefurbished Einstein yacht demonstrates innovative composites repair and redesign

Years of creative engineering work went into resurrecting the composites-intensive IMOCA 60 racing yacht — with award-winning results.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)