3D TPC structural preforming process lightens car doors

Automated cell manufactures and pre-impregnates continuous-fiber 3D preforms for injection/compression overmolding of parts with complex shapes, and tailored structural properties.

New lightweighting solutions for the automotive industry today must meet a plethora of demands. They must provide opportunities not only for weight savings but also cost savings in the finished part. They also require materials of reasonable cost that have the potential to be recycled. Thermoplastic-based composites could fit the bill, but have historically been held back by processing challenges.

A novel thermoplastic composite preform technology called QEE-TECH, developed by EELCEE Ltd. (Gyeonggido, South Korea), and related processing equipment, offers a lightweighting solution that reportedly meets these challenges. QEE-TECH is said to enable complex 3D shaping of thermoplastic preforms, which in turn reduces the cost and time required for high-throughput processing of thermoplastic composites. The equipment was manufactured by a joint venture company, QEESTAR, created with Gyeonggi-do-based robotics company Robostar Co. Ltd. To show the capabilities of the technology, which the joint venture is ramping up, EELCEE conducted a demo project with an automotive supplier involving a car door module.

Too viscous to process

Processing issues have previously devolved from the relatively higher viscosity of thermoplastic polymers, compared to their thermoset cousins. “The high viscosity of the thermoplastic resins place severe demands on impregnation methods, and subsequent forming operations raise important issues with regard to both preform integrity and tooling,” explains Queein Chang-Manson, CEO of EELCEE. In answer, the company is forming prepregged fiber constructs and then placing the pre-impregnated preform (the prepreg) into the mold and overmolding it. Thus solving the problem of poor impregnation of continuous fiber in the injection or compression mold by impregnating the continuous fiber outside of the mold and then placing the prepreg in the mold.

“By encapsulating unidirectional fiber and textile composite inserts in injection and compression molded parts, QEE-TECH provides a step-change in the design space for high-volume composite materials and facilitates the integration of multiple functions in a single part,” she explains. “This allows the designer the freedom to optimize both cost and performance by placing expensive high-performance continuous fiber material only where it is required while still maintaining the shape freedom afforded by lower cost, lower performance ‘flowable’ materials.”

“We have demonstrated 20-30% weight reduction (in exceptional cases up to 50%) and 10-20% cost reduction in a range of applications,” she adds.

CW first covered EELCEE back in 2013 after the company won a JEC Innovation Award at the 2013 JEC Asia event in Singapore for a thermoplastic bumper system manufactured via 3D QEE-TECH by molder Hanwha for Hyundai-KIA Motor Group, both based in Seoul, South Korea, (see Structural preform technologies emerge from the shadows).

More recently, at SPE’s 2016 Automotive Composites Conference & Exhibition in Novi, MI, US, Chang-Manson discussed the use of the company’s technology in the high-volume manufacture of composite automotive parts.

Automated process

The QEE-TECH 3D preform cell is designed to manufacture parts with complex shapes, multiple functions and tailored structural properties in a single-step operation. The fully automated process begins by pulling multiple continuous carbon or glass fiber rovings or tows from a creel through a series of dies that wet out the fiber with the appropriate resin (PA, PP, ABS, PEEK, etc.).

“Glass fiber has shown to be a preferred alternative when strength is the main requirement, while carbon fiber may be preferred if high stiffness is a priority,” says Chang-Manson.

The material passes through a preheating oven during the wet-out process. Next, the homogeneous molten tow is deposited on a jig fixed to a rotating, sliding or tilting table robot. A consolidation roller applies pressure to the tow during deposition. In all, the cell employs three robots — a head robot system that deposits the material, the table robot system, and a support robot system.

By rapidly placing the composite material into the desired 3D shape, an open, tailored 3D skeleton (prepreg) is created. Placed material is cooled via an air-jet system. The finished solid composite preform is then automatically cut and moved to the overmolding operation. Fully automated, the cell can be synchronized to integrated overmolding operations, providing high layup rates at temperatures up to 400°C (752°F). The 3D preform process is completed within a cycle-time on the order of 60 seconds.

“QEE-TECH is designed for the production of structural components in high volume,” stresses Chang-Manson. “Each cell offers a cycle time of less than one minute, producing from 10,000 to 300,000 parts/year.”

Typically, conventional neat or short fiber-reinforced polymers (PA, PP, PET, ABS, etc.) are used in the overmolding operation, typically injection or compression molding. “It is a non-isothermal process,” explains Chang-Manson. “The insert is preheated to just below melt, and the overmolding material has a temperature above melt. By doing this, the injection molding pressure enables a low void content and good bonding between the insert and the overmolded polymer, with a cycle time that is the same as for normal injection molding,” she adds. Reportedly, the preforming process does not negatively impact the cycle time of an overmolding process like injection molding when it is integrated into a production line. The cell can also be integrated to other composite manufacturing technologies, such as RTM and thermoforming.

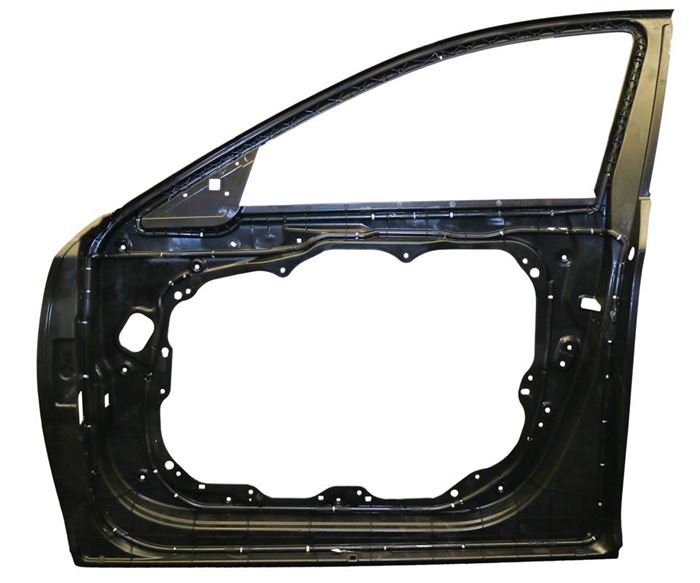

Composite door module

EELCEE recently partnered with Duckyang Ind. Co. Ltd. and MS Autotech Co. (both automotive parts manufacturers based in South Korea) to develop a composite door module. The research was supported by the Ministry of Trade, Industry & Energy (MOTIE), and the Korea Institute for Advancement of Technology (KIAT) through the “Encouragement Program for The Industries of Economic Cooperation Region.”

“The value of this concept lies primarily in the weight, cost and sub-part reduction that it offers with respect to a metal door module in the same price range,” explains Chang-Manson. By using continuous fiber preforms as local reinforcements in the thermoplastic door, a weight reduction of up to 20% can be achieved, she adds.

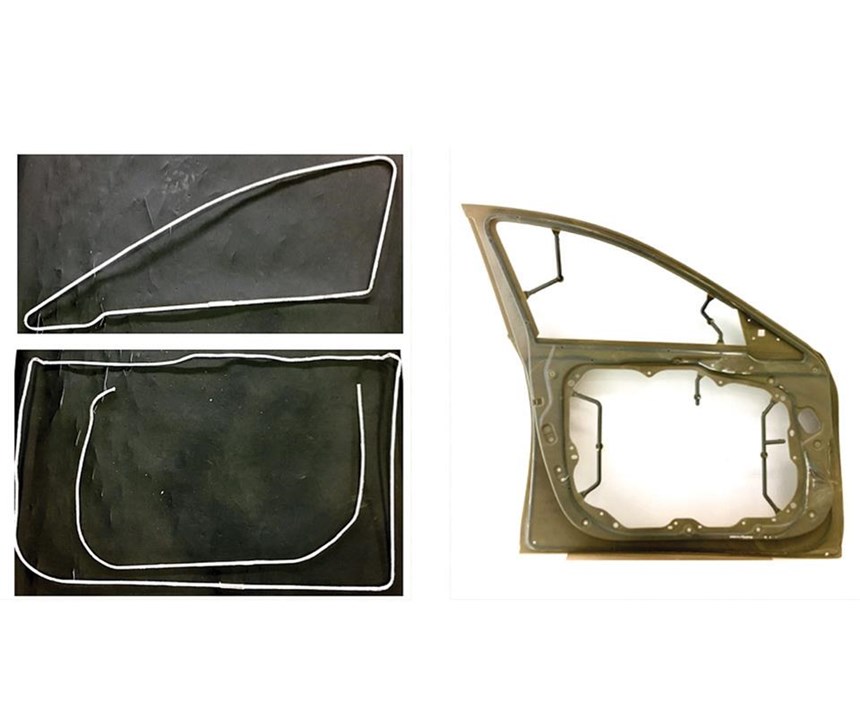

For the door module, EELCEE used a proprietary system it calls M-Tow — a braiding system that encapsulates the incoming uni-directional (UD) fiber tow with a suitable braid of fiber and/or polymer. This allows the tow to be heated and reshaped during the subsequent automated layup process without any loss of composite consolidation and polymer exudation. It also allows the braided tow to be self-supported during any form of 3-D layup.

The QEE-TECH process enables users to place a variety of 3D preforms for dedicated load introduction and load distribution. With proper design, it also can reduce the number of subparts. In this case, the thermoplastic composite door module consists of only six parts, compared to 17 parts in the legacy steel door.

“In developing the part, the whole value chain needs to be considered: manufacturing process and tool design, assembly and end-of-life,” notes Chang-Manson. “The introduction of local inserts can improve performance, but they entail an increase in complexity. It is very important to define which aspects of performance should be prioritized to keep complexity to a minimum.”

Re-engineering of the door focused not only on weight reduction but also on engineering strength. Extensive testing is being performed on various preforms with different materials combinations and shape configurations to verify process reliability and product performance.

“Our partners are pleased with the prototype parts that have been produced,” says Chang-Manson. “They are dimensionally stable and the parts look promising for high-volume production.” Hyundai Motor Co. reportedly has followed the door project closely and is considering adopting the technology for production. After testing is completed, EELCEE plans to contact other OEMs.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More