Large-format additive manufacturing (LFAM) is relatively new to the 3D printing marketplace but has quickly established a promising niche. Essentially, LFAM is a marriage of the motion systems used in today’s precision CNC-machining or laser-cutting machinery and 3D printing/extrusion heads modified for use in the larger format. Although much attention has been focused on using large-format 3D printers to build tooling for composite molding processes, they have also found use in building the finished parts themselves in one-off and very low-volume production. In either case, the technology is promising, and initial work, and the cost analyses derived from that work, suggests that large 3D printers, compared to current composite tooling and part fabrication practices, can offer significant cost savings, especially in total labor hours.

Benchmarking part-printing potential

Although development of the technology is ongoing, and the sample size of workpieces is still relatively small, an early demonstration project that entailed the printing of an excavator cab from carbon fiber-reinforced acrylonitrile butadiene styrene (ABS) provides a benchmark and insight into its capability to manufacture composite parts.

The cab was designed and manufactured by a consortium of industry and academic partners, called the Center for Compact and Efficient Fluid Power (Minneapolis, MN, US) using Cincinnati Inc.’s (Harrison, OH, US) trademarked Big Area Additive Manufacturing (BAAM) machine. The cab components were printed at the US Department of Energy’s Oak Ridge National Laboratory (ORNL) Manufacturing Demonstration Facility (Knoxville, TN, US). Together with a 7-ft (2.13m) long excavator arm, 3D-printed from carbon steel, and a 13-lb (5.9 kg) aluminum heat exchanger laser printed via a powder-bed-based process, the cab is one component of the first fully functional, hydraulically powered excavator with its key, critical components built using additive manufacturing technology. The project is referred to holistically as the Additive Manufactured Excavator (AME), and the machine was unveiled at the 2017 ConExpo/ConAGG show in Las Vegas, NV, US.

The cab was 3D printed with a ABS compound containing 20% chopped carbon fiber, supplied by Techmer PM (Clinton TN, US) and now trademarked as Electrafil ABS 1501 3DP. The resin is specially formulated for pellet-fed, large-format printing, which, depending on the application, may require higher stiffness than achievable with similar glass-filled formulations. The resin system has a reported flexural modulus of 1.8 msi, compared to Techmer’s 20% glass-filled grade, also targeted for BAAM applications, with a modulus of approximately 0.9 msi. The carbon fiber/ABS has a melt temperature in the 220-260°C range, a moisture content of 0.1% or less; and dries in approximately 4 hours at 80°C.

The 48-inch wide by 54-inch deep by 65-inch tall (1,219 mm by 1,372 mm by 1,651 mm) cab was printed in six separate parts (two sets of three) — four side panels (including a two-piece front panel comprising an upper and lower section) and a roof. The printer was Cincinnati’s Size-2 BAAM system, which has a build envelope of 240 by 90.74 by 72 inches (6,096 by 2,305 by 1,820 mm) in the x, y and z dimensions, respectively.

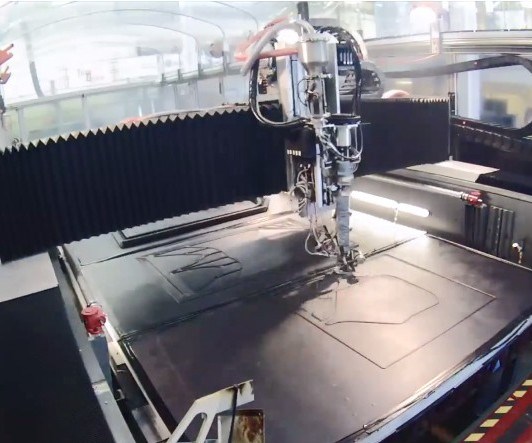

Rick Neff, Cincinnati’s additive manufacturing product and sales manager, says the critical components of the machine are the extruder and motion system, which facilitates fast, accurate part production. “We adapted a CNC motion system to a 3D printer, and program it with the same code we use for laser-cutting steel,” he says, noting that Cincinnati developed the machine in cooperation with ORNL. The system uses a lightweight aluminum/honeycomb gantry and brushless, magnetic linear servomotors with dynamic flow control that matches the extruder speed with motion of the head to deliver consistent bead width and placement. Nominal extruder speed is 2,500 ipm (63 m/min) in the x and y directions. Accuracy for absolute positioning and repeatability in the x and y axes is cited as ±0.005 inch (±0.127 mm).

Real-world prototype

Although the cab was built as a prototype demonstrator, Neff emphasizes actual real-world structural parameters figured into its design, because the AME was to be operational. “We didn’t just build a box with four windows,” he says, reporting that engineering students from the University of Illinois who participated in the project used CAD software to design the parts, optimize the topology and meet anticipated structural loads. A key concern in terms of loading was crush-resistant occupant protection in the event of a rollover. As a prototype, the cab was neither tested nor qualified to a formal crush-resistance standard, but the intent of it was inherent in the design. When the cab design was finished, the CAD model of its parts was evaluated for the best way to print them. Each individual solid-model part is exported as an STL file into “slicer” software developed internally at ORNL, which effectively slices the parts into discrete layers; these layers, programmed into machine code, form the base units, as it were, of the build using BAAM.

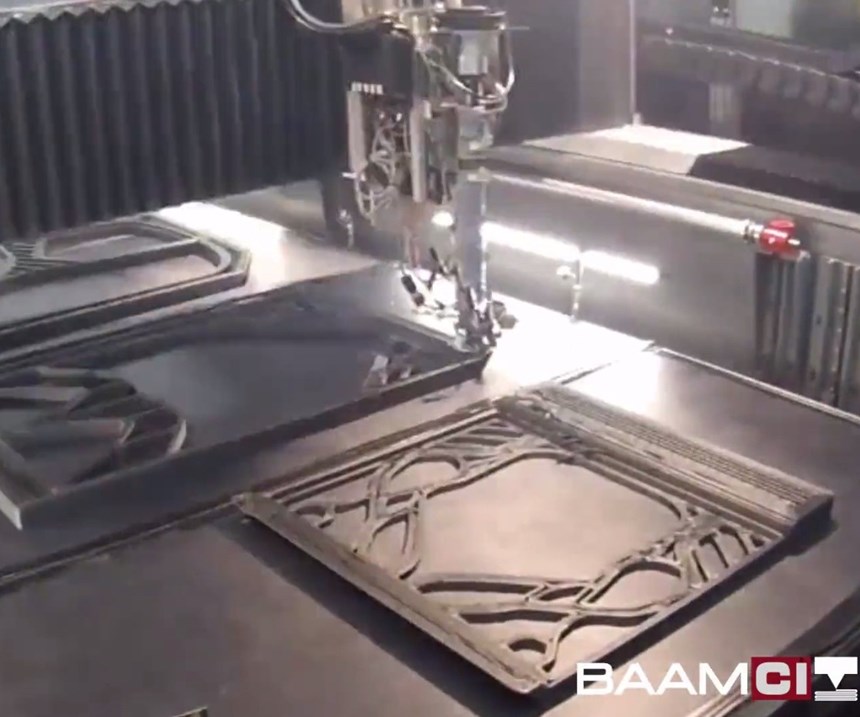

Each part was printed horizontally, on the BAMM machine bed, with wall thickness built up by laying successive beads of material over the semi-dry, solidified layers beneath it. The carbon fiber/ABS was extruded under approximately 13 MPa of pressure with a nominal bead width of about 0.25 inch (6.35 mm). Because the material requires about one minute to cool and solidify before another layer of material can be deposited over it, to avoid sag, distortion or other dislocation, the machine is programmed to avoid any machine lagtime by keeping the extruder busy elsewhere depositing beads, and then returning it to deposit another bead when a safe margin of safety for cooling has been allowed. The cab components have an average wall thickness of 1.5 inches (38.1 mm), or about 10 bead layers (see Steps 1 and 2, above).

The same, but a big difference

Small-scale 3D printing machines, using methods such as stereolithography (SLS) and fused deposition modeling (FDM) equipment, have been on the market for more than 20 years, whereas as large-format machines, BAAM is one or two current commercial options, have only been available recently, the two technologies invite comparison; the cab build highlights the similarities and differences.

For one, today’s LFAM systems use extruders modeled on or take their inspiration from the FDM systems used in the small-format 3D printer segment. The extrusion process and fundamentals of building up parts by layers are, except for scale, identical. “You can learn a lot about 3D printing from a desktop machine before you make a part on the BAAM,” Neff says. At the same time, he cautions, there are functional differences. A small-scale 3D printer, which typically is used to make models and prototype parts, extrudes a fine, thin bead of plastic, which cools and solidifies nearly instantly. There is, then, no necessity for the one-minute cooling interval noted above. This allows bridging between parts and part sections with no support structure. On the other hand, a large-format 3D printer, such as BAAM, is designed for commercial applications, so making large parts via extremely thin layers would be cost ineffective. Consequently, large 3D printers extrude a bead perhaps 25 or more times thicker. The thicker bead, however, won’t bridge much more than a very small gap, without sagging, a fact that has implications for part design (see the second photo, above, titled “3D printing and bridging gaps”).

A thicker, wider bead also precludes the printing of a part with smooth visible surfaces, necessitating finishing — machining, filling, sanding, priming and painting or other finish coating.

With that caveat, there is an exceptional upside in the potential to exploit a modelmaking/CNC machining-free way to make production tooling and a tooling-free way to make one-off and few-of-a-kind finished parts. Additive manufacturing allows you to redesign things in a way you never have before,” says Lonnie Love, a corporate research fellow at ORNL. Love, who oversaw the printing of the cab at Oak Ridge, says the slicing software is the critical component, which generates the toolpath and automates the process that enables CNC machining to become, essentially, CNC “adding.”

After printing, the parts were removed from the machine bed and the cab was assembled with a combination of snap-fit joints, screws and adhesive. The team used a rubber-hardened PLIOGRIP epoxy adhesive from Ashland (Columbus, OH, US), specially formulated for bonding plastic parts.

Once the cab was assembled, Tru-Design LLC (Knoxville, TN, US), a composite manufacturer and R&D company, and a member of the Oak Ridge Carbon Fiber Composites Consortium, carried out a detailed surface finishing process, entailing the following sequence of steps: masking, spraying of self-leveling filler/coating, sanding, applying of primer, painting and clearcoat (see photos).

PPG (Pittsburgh, PA, US) supplied the primer, paint and clearcoat. John Miller, VP of sales with Tru-Design, reports that the self-leveling filler/coating is a patent-pending material, called Tru-Design TD Coat RT, for achieving a Class A surface finish on carbon fiber-reinforced composite parts. Tru-Design, which had previously participated on a project to 3D print a Shelby Cobra body with BAAM (see for Detroit Auto Show”Shelby Cobra“ORNL ‘prints’ ), also conducted at ORNL, developed the material jointly with the Polynt-Reichhold Group (Durham, NC, US). The latter manufactures the product, which is sold exclusively by Tru-Design. Tru-Design now sells the Tru-Design TD Coat RT product for printed and molded composite tooling and parts, as well as a high-temperature version for tooling used in autoclaves.

Love calls the material a potential game-changer for achieving Class A finishes with carbon. “When the parts come off the printer they have a sort of corduroy, ribbed texture,” Love says. “In the Shelby project, we learned sanding on carbon-fiber reinforced plastic is a nightmare.”

The TD Coat RT, which cures in 4 hours at room temperature, serves a three-fold purpose: it fills the “corduroy” print lines and other surface imperfections, acts as a sealant and chemically bonds to the composite substrate. The coating provides, after a light hand-sanding, a smooth, paintable surface. Using the material, Love reports, the excavator cab surfaces were finished in a fraction of the time required for comparable surfaces on the Cobra.

For precision parts and most tooling, application of the coating must be accounted for in the thickness of the final printed part, Love says. In the case of the excavator cab, the effect of the coating on final thickness was insignificant. Of greater potential consequence, especially for the design of mating surfaces, is part shrinkage: The carbon fiber/ABS resin used to print the cab shrinks about 0.5%, a shrinkage rate similar to injection molded parts.

Going commercial in aerospace

Neff reports selling three BAAM systems to three customers, which now use them to make production tooling for aerospace composite parts. Indeed, tooling currently appears to be best near-term commercial application for LFAM. But Love believes there are certain applications in which using a large-format printer to directly manufacture one-off parts makes sense. He reports using ORNL’s BAAM machine to make furniture, including a bar counter, benches and stools, for a company pavilion at the 2016 Design Miami Show. In a unique twist to this project, the parts were made from a bio-composite, comprising bamboo fiber and PLA resin compounded by Techmer PM. The project consumed more than 10,000 lb of resin.

Large format 3D printing is admittedly in its early stages, with designers and fabricators still progressing through a learning curve while machine suppliers strive to enhance and hone features. On the wish list for Neff is off-the-shelf machine programming software, as well as a full suite of design optimization and simulation software for the additive process. Currently, he reports, design optimization relies too much on trial-and-error.

Already viable, LFAM’s wider adoption and commercial success hinges on how well it outperforms current toolmaking and fabricating practices. That, in turn, depends to a great degree on how soon and how extensively the wish lists of printer suppliers and users are granted and fulfilled.

Related Content

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)