Automating composites production for ease of use and affordability

Schmidt & Heinzemann innovates composites workcells with German quality and small-company flexibility — “modules customized per product and program is the key.”

I’ve showcased a lot of companies that offer automation solutions for composites manufacturing, including those in my 2015 article on turnkey manufacturing systems and another list of companies in my print articles and blog series on Automated Preforming. One company I haven’t yet covered is Schmidt & Heinzemann (Bruchsal, Germany). Sara Black wrote about the company’s automated bonding system in a post-JEC blog earlier this year. But my focus here is the company’s approach to automated preforming, which it claims produces complex 3D preforms with short cycle times and reproducible high quality.

SOURCE: Schmidt & Heinzemann

Company Background

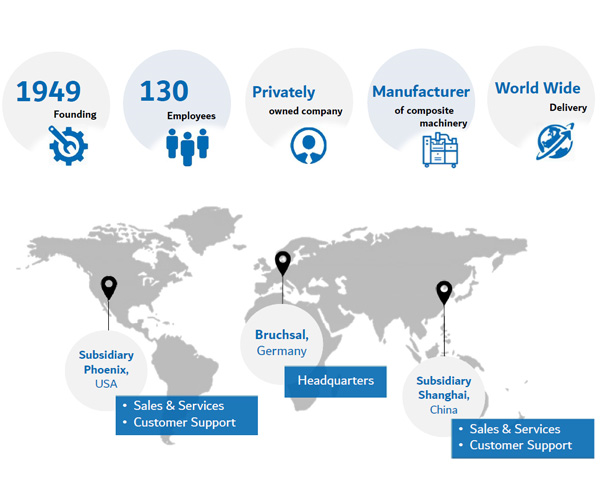

Schmidt & Heinzemann has a long history in composites, developing sheet molding compound (SMC) production lines since the 1970s. The company has:

- Committed to expanding and supporting the US and China as key markets with subsidiaries in each;

- Announced a strategic partnership with Eclipse Automation (Cambridge, ON, Canada) to provide the highest level of technology-enabled customer service and support;

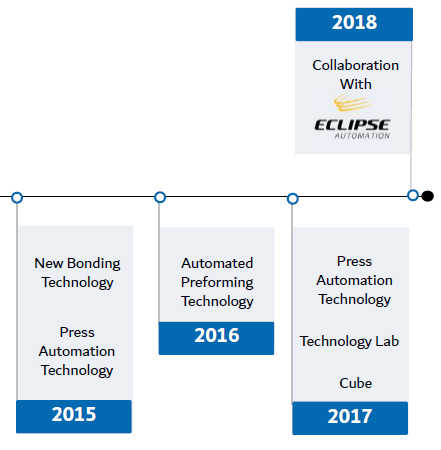

- Developed interesting bonding, press and preforming automation over the past few years;

- Amassed an impressive list of references.

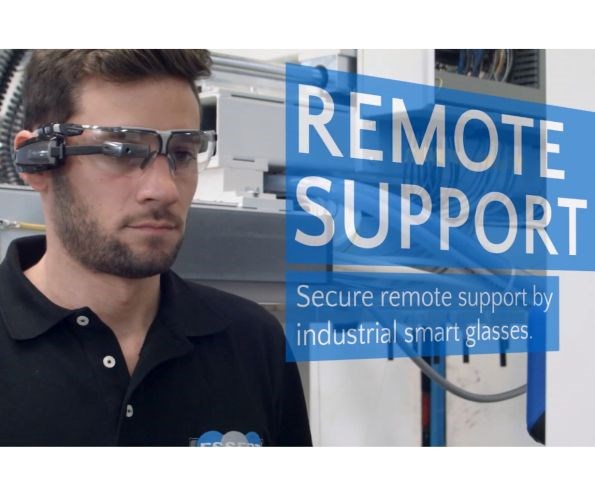

Schmidt & Heinzemann has developed “augmented automation” to provide easy-to-use, timely support for their global customers. SOURCE: Schmidt & Heinzemann.

https://www.youtube.com/watch?v=gNRUz9CRKpI

Automated Preforming

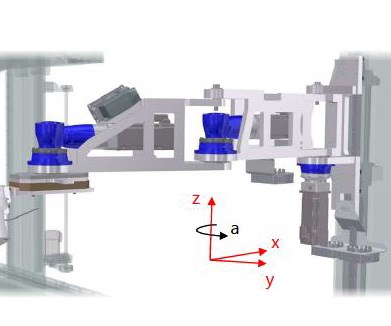

“We have developed a concept for automating preforming that uses single robotic arms that operate from a gantry system,” says Schmidt & Heinzemann North America president and CEO Christian Fais. The arms are called SCARAs which stands for Selective Compliance Assembly (or Articulated) Robot Arm. Developed in the late 1970s/early 80s, they have become the workhorse in affordable automation, offering:

- Fast, repeatable point-to-point movements

- Reliable, repetitive accuracy and precision, especially with tight-tolerance operations

- Robust performance with heavy workloads and in harsh environments

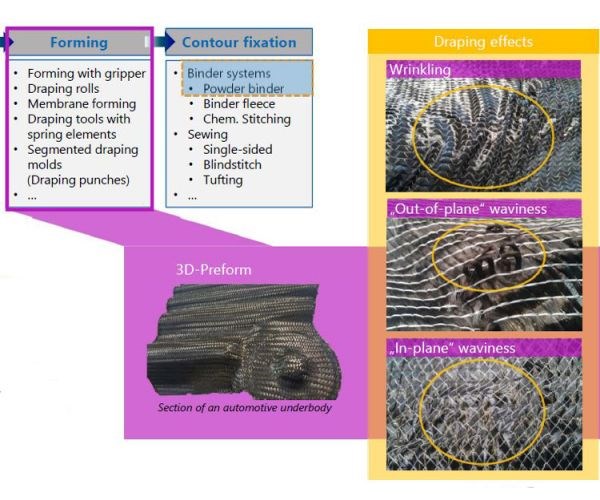

“The main issue that has evolved in preforming is wrinkles.”

SOURCE: Schmidt & Heinzemann.

“These single arms are used for draping composite fabrics during the production of preforms for resin transfer molding (RTM),” says Fais. “Over the past few years, the main issue that has evolved in preforming is wrinkles.” Here, Fais is referring to the basic steps in automated preforming of noncrimp or woven fabrics, which include selecting and cutting the fabrics, typically from rolls, picking and placing the cut blanks onto a preforming tool and then consolidating the stacked blanks into a 3D preform. “Most other suppliers hold the cut blanks with a frame,” says Fais. “We hold them with these SCARAs which also use end-effectors that have been developed to behave like hands. This results in less wrinkles because we are enabling an adaptability similar to human hands but without the loss of repeatability. The frame approach is not as flexible to finesse the draping.”

SCARAs are known for being able to perform motions similar to that of a human arm. They have a shoulder and elbow joint, as well as a wrist axis and vertical motion. The shoulder and elbow joints rotate around the vertical axes, while motion at the wrist is limited — it can rotate but not tilt. This turns out to be key for its excellent pick and place capability, giving it a unique combination of rigidity and flexibility. SCARAs are also known for being very compact and easy to program without having to know robotics.

SCARAs offer high precision at low investment costs vs. industrial robots.

SOURCE: Schmidt & Heinzemann.

These characteristics carries through the design of the whole automation system. “It is structured like a CNC machine with a control that is easy to operate,” says Fais. “You don’t need a special operator with knowledge about robotic controls.” And yet, the system doesn’t lack for precision, as Fais explains, “it has a line control system from Beckhoff which is similar to the Rexroth control system from Bosch.” In other words, Schmidt & Heinzemann is exploiting German supplier Beckhoff’s “New Automation Technology” featuring universal and open control for worldwide automation solutions — offering the quality and reliability of industry leaders like Bosch but at an affordable price. Schmidt & Heinzemann is also combining gantry and robot technology in a way that allows a standard platform which is easily tailored. “The real secret to preforming is that you must adapt the automations to the specific part and program needs,” Fais asserts.

Case in point, one of Schmidt & Heinzemann’s automated preforming cells has been installed at the KDX Europe Composites R&D Center in Weyarn, Germany, just south of Munich. An affiliated company of Kangdexin Composite Material Group (KDX, Zhangjiagang, China), the 3,000-m2 KDX R&D center has partnerships with KDX Roding Europe Automobile Design Center, Forward Engineering and TU Munich, as well as automotive OEMs and Tier 1 suppliers. The preforming cell installed here has so far been modified to demonstrate composite leaf spring production, picking and placing cut blanks measuring 300-2,200 mm in length and stacking these accurately into a preform up to 100 mm high. These preforms are then trimmed by an ultrasonic cutter to provide clean edges, all the while supported by a 6-axis robot to maintain tension on the constituent fabric pieces.

Fais claims his company’s new automated preforming technology produces complex 3D preforms with short cycle times and reproducible high quality. Other benefits include:

- Robust process technology

- Precise stacking

- Ability to activate thermoset and thermoplastic binding systems

- Fully automatic forming process

- Space- and labor-saving design

- Reliable line control with an easy teaching process

- Segmented draping stamps allowing sequential forming

- Ability to precisely place local reinforcement elements, core materials or other inserts

Schmidt & Heinzemann’s newest development is a full automated preforming line in its new development center in Bruchsal, Germany. “We invite customers to come work with our team and trial different options to develop a successful process that meets their needs,” says Fais.

He will discuss the full spectrum of this technology in much more detail at CW’s Carbon Fiber 2018 (Dec 4-6, La Jolla, CA, US) conference, and will also touch on other Schmidt & Heinzemann composites developments including:

- Automated bonding system at an automotive Tier 1 supplier

- Press automation include loading and unloading

- Automation of part cooling, deburring and cleaning

- Direct fiber spraying technologies for fast manufacturing of 2D and 3D parts or preforms.

|

Press automation and direct fiber spraying for fast 2D and 3D preforms.

SOURCE: Schmidt & Heinzemann.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More