Boat propellers with replaceable, interchangeable blades

Long glass fiber-reinforced polyamide makes this modular propeller tough enough for a challenging application, eliminating costly prop repair.

Every motorboat owner has a tale of hitting a submerged obstacle or boat ramp and damaging a propeller. Typically metal, it must be removed and taken to a prop repair shop, then sandblasted, bent, welded and restored to original shape — a lengthy and expensive process. Brad Stahl, founder/ owner of Piranha Propellers (Jackson, CA, US) and an aerospace engineer, says a conversation with his brother 25 years ago gave him an idea that is today reducing the cost of damage and eliminating those costly trips to the prop shop for his still growing customer base.

“At that time, I was working on an unmanned aerial vehicle project that was employing wooden propellers, and I wanted to find something lighter and less expensive. My search for composite materials brought me to long fiber-reinforced thermoplastics,” recalls Stahl, “and I realized that they might work for a boat propeller.” His work since then resulted in a propeller with a modular composite design, featuring quickly interchangeable blades, and a successful business manufacturing modular three- and four-bladed propellers for every major outboard motor.

The art of propeller design

Unlike ocean-going vessels, which travel at relatively low speed powered by large propellers (read about composite props for large ocean-going vessels in “Composite propeller for Royal Navy minehunter” under "Editor's Picks" picks on the top right), faster, more mobile small boats depend on small props that turn at very high speeds, says Stahl. In water, that presents great challenges: “When I would design a propeller for an airplane, it was a straightforward problem. You know how they’re going to work, plus or minus a few percent, and you’re done. That’s not the case with marine propellers.” One reason is cavitation. As the curved blades turn through the water at increasing rotational speeds, the pressure on the low- pressure side of each blade drops below the water’s vapor pressure (given the water temperature) causing boiling — the formation of millions of bubbles that degrade the flow regime. Further, says Stahl, the outboard’s exhaust gases pass through the propeller hub, further degrading the flow, and the motor’s lower unit, which sits below the waterline, also disturbs the water. The result? “It’s a really messy flow environment that makes it impossible to perform CFD [computational fluid dynamics] or any kind of hydrodynamic analysis,” says Stahl. “There are too many unknowns!”

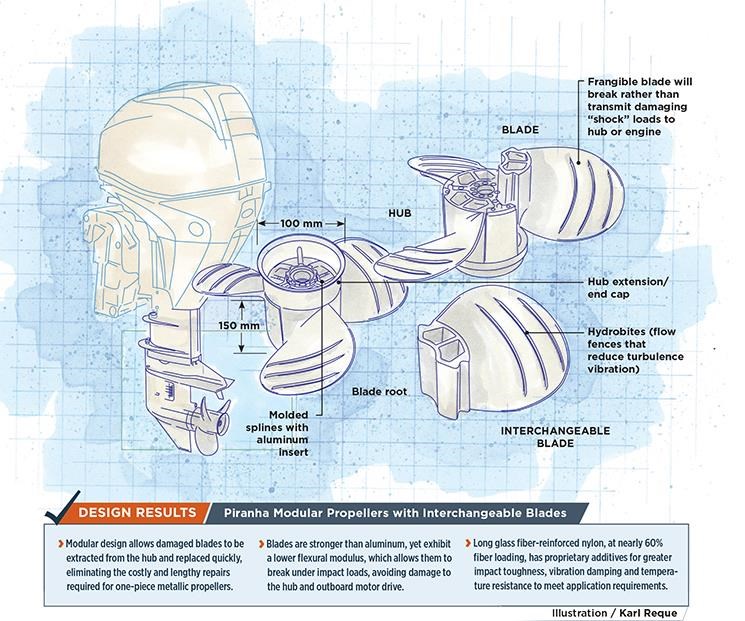

He tackled the problem, nevertheless, envisioning a propeller with a 150-mm long, 100-mm diameter cylindrical hub with a central cavity that allows the propeller to slide over the outboard driveshaft with three or four longitudinally shaped slots for inserting blade roots. A 75-mm long hub extension would fit on top, secured with a large nut that would grip splines molded in the central cavity and, when tightened, secure the blades in place. A series of successively larger hubs would be built to the boating industry’s outboard motor size range (A, B, C, etc.), corresponding to horsepower rating. Each hub, then, could accept blades of different pitches, or degrees of curvature (in general, a higher pitch delivers greater thrust for a given horsepower). The parts would be injection molded with a fiber-reinforced thermoplastic. “I knew from my UAV work that glass-reinforced nylon could work, and would perform as well as metal in this application, at a more affordable price point,” says Stahl. Stahl’s target cost for a replacement blade was approximately US$25.

Stahl used software from NISA (Troy, MI, US) to conduct a structural analysis and develop a finite element (FE) model to understand how the modular prop blades and hub would behave under load. He assumed a 260-hp motor would deliver about 365 kg of thrust to the prop (typical for a small recreational boat), or 91 kg to each blade (assuming four blades), which helped him determine appropriate blade and hub material thicknesses. Blade shape was derived from aluminum props that had been proven in service. According to Stahl, “90% of the load on the blade is thrust, causing bending, which means that as the prop spins, the blade bends under the load.”

Stahl’s blades had to be thick enough to handle the thrust- induced bending loads, yet frangible enough to act sacrificially to save the hub and, in turn, the engine from damage given the unexpected, extra load of hitting a submerged object.

Initial molded prop blade prototypes were proof-tested concurrently with aluminum blades of similar shape, via static point bending tests in holding fixtures. The tests confirmed that the composite blades were stronger. But, as expected, the lighter composite blades lacked the stiffness (flexural modulus) of aluminum. To accommodate the bending that would occur under load, subsequent blades were overdesigned in terms of curvature: “I knew the flexural modulus properties of long-fiber composites when designing the propeller,” said Stahl. “The molded part had to be slightly distorted so that when the blade is experiencing propulsion forces in the water, it would straighten and assume the proper shape to maximize thrust.” The composite blade’s lower shear strength compared to aluminum, also verified in testing, would enable the blade to absorb the energy from minor impacts, but break away and release energy under high impacts.

Tweaking material, updating designs

Stahl’s first material choice was a standard 60% long glass fiber-reinforced nylon 6. He recalls that testing with higher horse-power motors was successful: The blade shape delivered thrust as predicted, and in strike tests, breakage occurred as desired. But testing also revealed that the reinforced nylon splines inside the hub could not handle the shear loads from the propeller input shaft: “The hub could handle the normal loads but not the shear when a strike would occur,” he says. The solution was to co-mold a splined aluminum core insert inside the hub.

Material questions arose, however, when smaller propellers were tested on lower horsepower, two-stroke motors: Props were breaking under normal operating load. “We did a lot of testing,” says Stahl, “and found the higher harmonics and vibration in the two-stroke motors caused the composite to fatigue.” Although a toughening agent added to the long-fiber thermoplastic improved its vibration damping, Stahl ultimately was dissatisfied with the prop’s cosmetic appearance. A search for an alternative material led him to PlastiComp Inc. (Winona, MN, US).

PlastiComp’s pellets are made with continuous glass fiber strands, pulled through an impregnation die filled with molten polymer, says PlastiComp’s VP of technology Eric Wollan. “It’s a rod of aligned glass fiber and polymer, at fiber volume up to 60%, which we typically provide in pellets about 12 mm long.” For Piranha, PlastiComp provides a proprietary formulation with reportedly 40% greater impact resistance than standard long fiber-reinforced materials, through the use of special additives that improve ductility and damp engine-induced vibration over a broad temperature range. It also contains carbon black for ultraviolet resistance and additives that impart a semi-gloss surface. “PlastiComp’s Complēt MT long glass fiber nylon material easily provided the surface finish I wanted for our propellers,” relates Stahl.

Although the initial propeller design was realized early on, Stahl continues to tweak product performance. One recent advance, Hydrobites, are small “flow fences” that control water flow and reduce turbulence vibration on the high-pressure side of the blades for better acceleration and maneuverability in tight turns. “Injection molding makes it easy to add feature details, like our Hydrobites, that would be difficult and expensive to produce in metal,” Stahl points out.

Piranha’s latest propeller iteration, intended for houseboats and service barges, improves reverse thrust, says Stahl. “It doesn’t take much for inexperienced people to have difficulty because reverse thrust performance is significantly lower than forward thrust.

Propellers are designed to push, not pull.” Based on some proprietary blade design changes, Piranha’s Hydrothrust propeller, he reports, provides 400% more reverse thrust than the company’s standard propellers, with no change in forward thrust, and twice the reverse thrust of competing metal props.

A practical prop without the repair costs

Stahl reports that his company’s injection molding process is very fast and problem-free. The modular nature of the design means that fewer molds are needed, which helps keep costs low. As an example, for the hub and hub extension parts to fit A-Series outboards, only two molds are needed because any blade, regardless of pitch, fits into the slots. He adds that all Piranha hubs are guaranteed for life, and of the tens of thousands sold each year, only a handful are returned for replacement.

As a result, Piranha’s propellers are affordable and, with easily changed blades, have been an unqualified success, as evidenced by its extensive customer base. The ability to change a damaged blade instead of having to replace an entire prop reduces boat ownership cost. Given the low price point, in fact, customers often buy interchangeable blade sets of different pitch, enabling them to tune their boat’s propulsion thrust to the intended use. Boating for speed? Transporting heavy loads? They’ve got the best of all worlds.

Related Content

MerConcept, Extracthive integrate rCF components into racing yacht construction

Development and integration of recycled composite ballast dorade vents for an IMOCA class yacht and other ongoing projects demonstrate a push for greater circularity in the marine industry.

Read MoreLarge-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

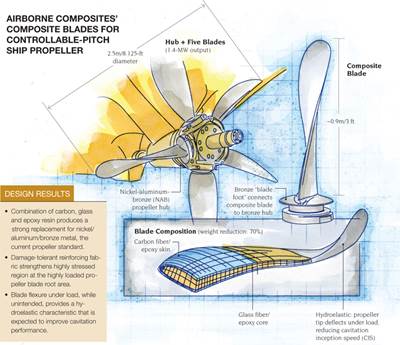

Composite propeller for Royal Navy minehunter

Composite-for-metal replacement brings multiple benefits.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More