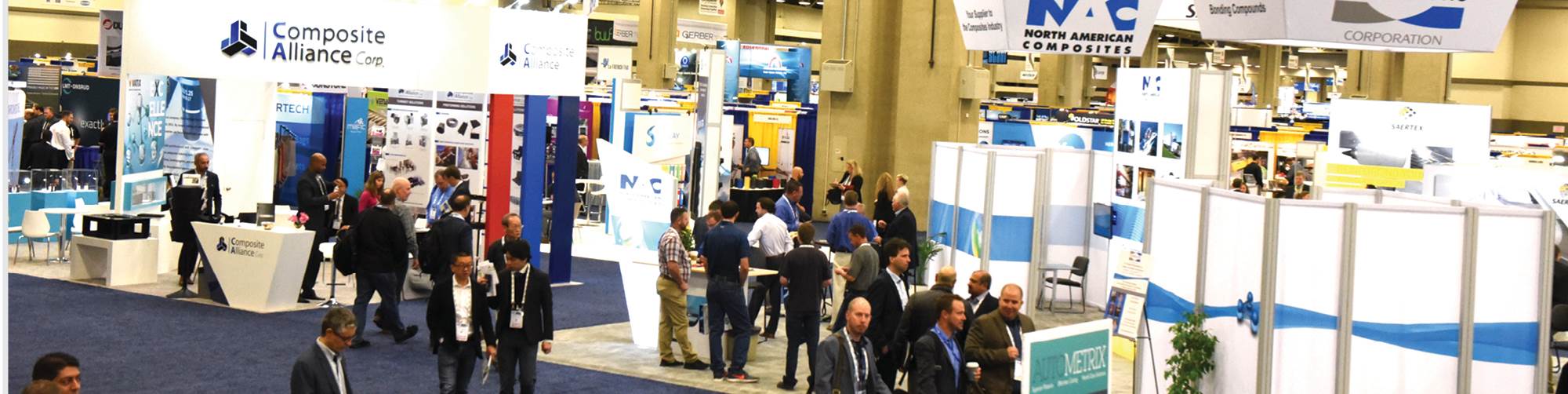

CW Photo | Jeff Sloan

The world’s largest composites-related trade exhibition is JEC World, held every March in Paris. It’s a great show — busy, crowded, bustling, full of technologies and exhibitors from throughout the composites supply chain. The aisles are crammed with attendees representing every major end market the industry serves. Three days at JEC World makes you feel like you’re in the middle of the composites manufacturing universe, and nothing else matters.

There’s just one problem. It’s very likely that you, as a subscriber to CompositesWorld, have never attended JEC World. And if you have attended, it’s even more likely you’ve done so only once or twice. The reason? The center of gravity in the world of composites is in North America, and if you are an engineer or plant manager or VP of manufacturing for a composites fabricator in the U.S. or Canada, traveling to Paris annually to attend JEC World is just not economically feasible, no matter how valuable and important the show is. Indeed, each year the fraction of JEC World attendees from the U.S., as reported by show organizer JEC Group, is substantially smaller than the fraction of composites professionals from the U.S. that make up the entire global composites industry. Still, it’s a great event — hard to beat.

CW has compiled a list of what you can expect to see at many of the exhibitor booths at this year’s CAMX.

There is no direct analog to JEC World here in North America — nothing that compares with the size and intensity of JEC World. What we do have, however, CAMX, comes pretty close. CAMX, for those of you new to composites, or for those of you who just plain forgot, is a relatively new composites exhibition, having begun in 2014, in Orlando, Florida. You might recall, prior to 2014, the American composites trade show scene was cleaved by two major events: SAMPE’s conference and exhibition in the spring and ACMA’s conference and exhibition in the fall. The former catered to the aerospace end market; the latter catered to everything else.

In 2014, however, the leadership of SAMPE and the leadership of the American Composites Manufacturers Association (ACMA) decided it was time to forgo this segregation and develop a single event designed to meet the needs and expectations of the entire composites industry. Thus, CAMX was born — a conference and exhibition for the entire composites industry supply chain, from raw material suppliers to machinery manufacturers to intermediates producers to moldmakers to fabricators and OEMs. And all end markets are fair game, including aerospace, space, automotive, wind, architecture, marine, industrial, consumer, sporting goods and on and on.

CAMX 2019 represents the sixth iteration of the show, and it will be held this month in Southern California at the Anaheim Convention Center, Sept. 23-26. Unlike JEC World, CAMX has not had a couple of decades to mature and grow, but it has had time to become the largest composites trade event in the world’s largest composites market, and that’s meaningful. CAMX organizers have worked diligently each year to evolve the show and make sure the event is useful, relevant and a source of great technical information.

This year’s CAMX is expected to draw more than 8,000 attendees and 550 exhibitors. Further, one of the strengths of CAMX is a robust conference program, which this year offers more than 180 presentations covering additive manufacturing, bonding and joining, workforce development, design/simulation, sustainability, processing technologies and testing.

In short, you have in CAMX a composites trade event that is easily accessed and is a great source of technical and market information about where and how composite materials are being applied today.

Preparatory to the show, we asked all CAMX exhibitors to send us whatever information they have about the products, technologies and services they are featuring in their booths. You will find on p. 20 of this issue a preview of that exhibit information. CW will, of course, be at the show itself, and we hope you will be there as well. And if you are at CAMX this month, I encourage you to stop by and visit us in booth K72. I look forward to seeing you in Anaheim.

Related Content

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreNASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Read MoreAMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreRead Next

CAMX 2019: Exhibit previews

CAMX 2019 is just around the corner, so it’s time to start thinking about what you will encounter on the show floor.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More