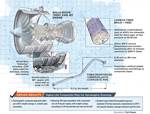

Composite aeroengine dressing to wing driveshafts, SHM and more

For Sigma Precision Components (Hinckley, UK), composite pipe for jet engine dressing could be only the beginning.

For Sigma Precision Components (Hinckley, UK), composite pipe for jet engine dressing could be only the beginning (see CW’s feature story titled “Re-dressing aeroengines with composite pipes” by clicking on it under “Editor’s Picks” at top right.) Sigma’s managing director Mark Johnson says growing interest in its dressing solutions has opened opportunities to explore avenues for composites design and manufacture in other aircraft structure.

“About halfway through the program, we started to get a lot of interest from a wide range of potential customers,” says Johnson. The company spun off the technology as Sigma Lite and expanded it to include additive layer manufacturing (ALM) of end fittings as well as new lightweight metals technologies and hybrid solutions combining these with a variety of non-metals to replace traditional metal aerospace components.

In February 2015, Sigma won a UK-government funded Advanced Manufacturing Supply Chain Initiative (AMSCI) award to develop composite driveshafts used in the leading and trailing edges of aircraft wings. “Most aircraft use steel transmission shafts to send equal torque from a central power control unit to the left and right wings for gearboxes that actuate flaps and struts,” explains Andreae. “We not only will reduce the weight of these torque shafts, but also plan to incorporate sensors for structural health, load and temperature monitoring.” Structural health monitoring (SHM) is, in fact, a key objective for the SAGE ITD within Clean Sky, extending current engine capabilities to include optical and thermal systems for fault/crack monitoring of blades, but also researching next generation multifunctional structures which also integrate energy harvesting, local data storage and wireless data transmission (e.g., RFID, etc.). Rotating structures are an explicit objective, with demonstrations to be completed in 2015.

This short article is a Side Story to CW's main feature article titled, "Re-dressing aeroengines with composite pipes." To read that article, click on its title under "Editor's Picks" at top right.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.