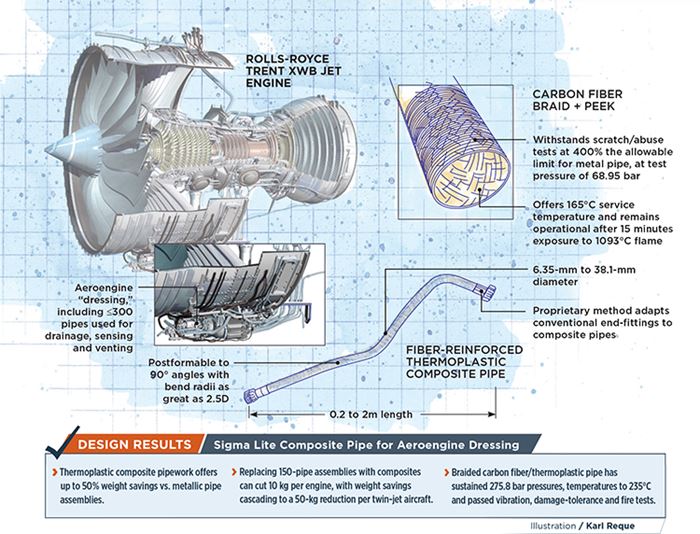

Re-dressing aeroengines with composite pipes

Sigma Lite braided carbon fiber/thermoplastic pipe cuts jet engine weight yet meets challenging design and manufacturing requirements.

Design Results:

- Thermoplastic composite pipework offers up to 50% weight savings vs. metallic pipe assemblies.

- Replacing 150-pipe assemblies with composites can cut 10 kg per engine, with weight savings cascading to a 50-kg reduction per twin-jet aircraft.

- Braided carbon fiber/thermoplastic pipe has sustained 275.8 bar pressures, temperatures to 235°C and passed vibration, damage-tolerance and fire tests.

Formed in 2005, Sigma Precision Components (Hinckley, UK) bills itself as a one-stop shop for new and aftermarket precision-engineered aerospace components. The fast-growing company reported annual turnover of almost US$60.58 million in 2015, and has long-term supply agreements with major OEMs and Tier 1s.

Although Sigma’s main products are rigid pipe and tube assemblies of metal, “we saw GKN, Airbus, Boeing and others increasingly turning to nonmetallics and composites in both airframes and aeroengines,” says Sigma’s managing director Mark Johnson, “but no one was working to develop this technology lower in the supply chain. So we put forward a technology roadmap to advance in this area.”

In late 2012, the company was awarded its first funded technology program, COMpipe, part of the Clean Sky initiative. Organized within the Sustainable and Green Engine (SAGE) 3 Integrated Technology Demonstrator (ITD), led by Rolls-Royce (Derby, UK), COMpipe’s goal to develop composite pipes for aeroengines would also contribute to SAGE 3’s goal of meeting ACARE (Advisory Council for Aeronautic Research in Europe, Brussels, Belgium) environmental targets (cick on “Aeroengine composites, Part 1: The CMC invasion,” under "Editor's Picks" at top right).

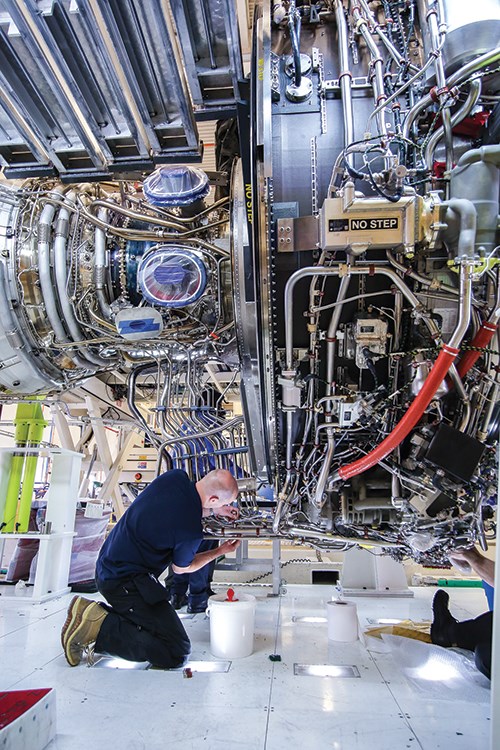

Updated aeroengine dressing

The objective was to bring aeroengine dressing — engine externals, including pipes and electrical wiring harnesses — into the 21st Century. Having already begun developing its carbon fiber reinforced polymer (CFRP) electrical harness rafts (see “Aeroengine composites, Part 2: CFRPs expand” under "Editor's Picks"), Rolls-Royce challenged COMpipe to develop a polymer matrix composite concept for piping used as drainage, scavenge, sensor and vent lines. Measuring variously 0.2m to 2m in length, these pipes must withstand internal pressures up to 31 bar, temperatures up to 165°C and corrosion from contact with Skydrol hydraulic fluid, oil and aviation fuel. “The harsh aeroengine environment also includes significant exposure to vibration and general abuse,” adds Sigma’s director of technology Michael Andreae. But perhaps the biggest challenge, depending on their location, is that pipes must be either fireproof or fire-resistant. Advisory Circular AC No: 33.17-1A, issued Aug. 3, 2009, by the US Federal Aviation Admin. (FAA, Washington DC, US), says fireproof means the part must withstand an average flame temperature of 1,093°C for a minimum of 15 minutes while still performing its intended functions. Fire-resistant structures must do the same for a minimum of 5 minutes. Metal pipes are, in general, inherently fireproof, Andreae notes, but meeting either standard would be no easy feat for a polymer composite. He adds, “And all of these requirements existed not just for the pipes, but for the end fittings as well.”

“There is also a high variety of complex 3D geometries in these piping systems,” Andreae adds. So the formed pipes must not only be thin-walled, but like their metal counterparts, must be postformable to accommodate various pipe configurations.”

The pipes had to be substantially lighter than conventional metal versions, but also cost-competitive, which could limit not only the choice of materials but fabrication processes as well. Goals here were daunting:

- A standard product with near-zero porosity in the walls and 100% leak-proof;

- A standard process that can produce 3D geometries like those in existing metallic designs;

- The ability to fully exploit automation in order to meet aircraft production rates;

- The ability to achieve qualification in a reasonably short time period, by Nadcap, the global cooperative program administered by SAE International’s (Warrendale, PA, US) Performance Review Institute (PRI).

Exploring design options

Sigma and project partner TWI (Cambridge, UK) began by comparing the state-of-the-art for metallic aeroengine pipes and for composite pipes used in a variety of applications, including nonaerospace. “We looked at both thermoset and thermoplastic material options,” says Andreae. Options included those with different fiber types and alternative methods for applying the fibers and resin, including filament winding, wet layup and braiding. “We also used some external consultants at this point to make sure we didn’t overlook any possible solutions,” he adds. In the end, the partners pursued thermoset and thermoplastic options. TWI concentrated on the thermosets and Sigma focused on thermoplastics.

“We felt this technology would prove more suitable with respect to manufacturing,” Andreae says of Sigma’s choice. “With thermosets, we would need a tool to mold the pipe into,” he points out, “but there could be 300 individual pipes to mold, thus, 300 different tools. This is impractical for commercial production.” Thermoplastic composites, however, could be formed using processes similar to those Sigma already employs for its metal pipe manufacturing, such as CNC bending machines.

In the end, carbon fiber braids and a PEEK-based resin system provided the best combination of performance and formability. Andreae says the pipes can be made using other fibers and thermoplastics, with strength tuned to particular applications, “but PEEK provides a very robust product.”

Next came exploration of a variety of designs and materials for end fittings. “We concluded that the most cost-effective path would be to enable the well-established, threaded metal connections we use in metal pipes,” says Andreae. “However, we would have to then revisit the composite design and make sure we could still achieve the promised weight reduction.” After a variety of methods were investigated, a proprietary process was developed that enabled efficient, high-performance joining of the end fittings to the composite pipes.

“We were already well-versed in the design demands. For example, you must position the fittings accurately, both with regard to the pipe end axially, but also rotationally,” Andreae explains. These pipes use a large variety of end fittings, for example, elbows, flanged connections and T- and Y-pieces that, for metal pipes, are often integrated into the pipe via welding or brazing. “We were trying to adapt our metal techniques to composites without constraining the overall design too much,” says Andreae. “We succeeded and did, indeed, demonstrate the required positional accuracy, but still within a process that can be scaled economically.”

Post-forming and passing tests

The next challenges were proving out the post-forming capability of the CF/PEEK composites and passing the required tests. According to Johnson, post-forming required the most development. “To adapt Sigma Lite for use with CNC metal pipe-bending equipment, you must take the composite back to its original melt temperature,” Andreae explains, “But this must be tightly controlled in order to maintain the composite properties and avoid inducing stress in the parts.” The now patent-pending process has been successfully demonstrated for angles up to 90° with a bend radius of 2.5D, with Sigma initially targeting pipe diameters (D) of 6.35 mm to 38.1 mm.

For fire compliance, “we tried a number of different solutions,” Andreae recalls, “from pipe without coatings, to using fire-retardant coatings and many other options.” The team discovered that any pipe with static air in it was unlikely to be fire-resistant, but if that same pipe was filled with liquid, it passed all tests swimmingly. “Still, the construction of the pipe is a big factor,” he cautions. “We had to ensure enough heat transfer out of the pipe. But with this accomplished, we met all of the test requirements for both fire-resistant and fireproof applications.”

Andreae says a vibration test protocol was developed with Rolls-Royce that excited the pipe assembly to its resonant frequency at a level of acceleration equivalent to 35G, using a fully instrumented shaker table. “We did this in three axes for eight hours,” he recounts, “and the pipes performed flawlessly.” Sigma also performed scratch and abuse tests on the composite pipes, followed by subjecting a deeply scratched pipe — damage was roughly 400% of the allowable limit for metallic pipe — to a pressure test at 68.95 bar, and it maintained its function without any leaks or degradation. After two and half years, the braided CF/PEEK could be molded and postformed into complex shapes using commercial-scale processes, and offered a 50% weight savings vs. metallic pipes while hitting competitive cost targets.

One step toward big leap

Having received much fanfare for its composite aeroengine pipe at the 2014 Farnborough International Airshow (Farnborough, UK) and the 2015 Paris Air Show (Paris-Le Bourget, France), Sigma is focused on refining and demonstrating manufacturability, targeting Technology Readiness Level (TRL) 6 by 2016. It is also talking to engine manufacturers and aircraft OEMs, and recently visited Commercial Aircraft Corp. of China Ltd. (Shanghai, China).

For Sigma, composite pipe could be only the beginning. Johnson says the company is exploring other avenues in aircraft structure (see “Composite aeroengine dressing to wing driveshafts, SHM and more,” below or click on its title under "Editor's Picks"). “We are becoming expert in how to introduce products that not only meet the stringent cost and safety expectations of today’s commercial aircraft,” says Andreae, “but, in time, we are surpassing these standards, delivering better-value products that improve efficiency and reduce our carbon footprint, all without a cost penalty — everybody wins.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

Aeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreAeroengine Composites, Part 1: The CMC invasion

As pressure for commercial aircraft fuel efficiency continues to mount, ceramic matrix composites evolve as they battle metals for application in the engine hot-zone and elsewhere.

Read More

.jpg;maxWidth=300;quality=90)