Connecting the Dots: Generative design, bionic structures and future composites

The trend shows cast and 3D printed metal, but fiber-reinforced composites offer the potential for multifunctional structures.

My vision for these “Connecting the Dots” blogs is to show connections that I see during my continuous research. To me, these are visual images that light up like a runway, pointing to a trend forming or a technology moving toward a tipping point. Sometimes it’s just a landscape coming into focus. I make no claims of futurecasting accuracy, only relationships that I see and find intriguing. My hope is that this type of blog will inspire you and stimulate new ideas for composites applications and technology developments.

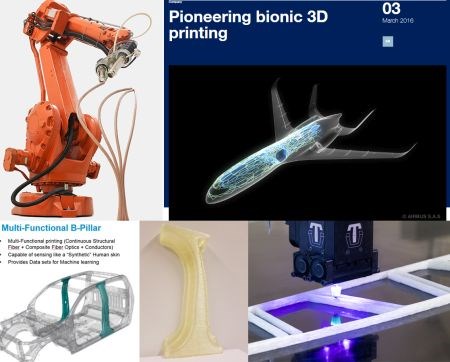

The first of these blogs is about how generative design is being used to develop lightweight, bionic structures and how composites may take this one step further, to integrate sensing and other functions.

In my blog “Generative design and continuous 3D fiber deposition” I explored how these two technologies enable and expand each other. “Generative design offers a much broader range of optimization and design possibilities,” says Massimiliano Moruzzi of Autodesk Research’s Computational Science group. Continuous 3D fiber deposition offers a means of fabricating these new designs as intelligent, sensing, multifunctional structures.

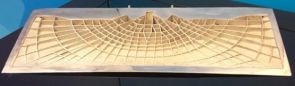

Most of the structures that result from generative design are very organic, such as the “bionic partition” that Autodesk worked with Airbus to develop for the A320 (top image above). Though metallic 3D printing was used for this partition (and for now infamous brackets), Moruzzi and others see more potential in fiber-reinforced composites.

Note that Airbus has pursued smart bionic aircraft for over a decade. I found a 2009 presentation by Henrik Rösner, Airbus Structure Engineering that discussed functional surfaces for passive and active flow control such as advanced riblets, elastomeric and photo-catalytic coatings and suction/blowing for laminar flow wings (watch for my upcoming blog on the BLADE project). It also showed self-healing composites, piezoelectric composites and multifunctional integrated design. The latter is a key focus of full-size fuselage demonstrators scheduled to be built next year as part of Clean Sky 2.

|

||

|

|

|

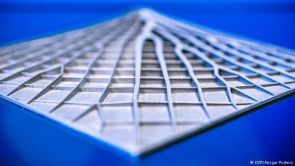

I saw the promise of bionic design illustrated in a presentation at the 2016 CFK Valley Convention on the ELiSE – Evolutionary Light Structure Engineering systematic approach to design optimization developed by the Alfred-Wegener-Institute (AWI, Bremerhaven, Germany). ELiSE uses biological models to develop novel engineering solutions such as the adaptive and fractal honeycomb (higher stiffness and up to 20% lighter) and automotive B pillar above.

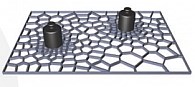

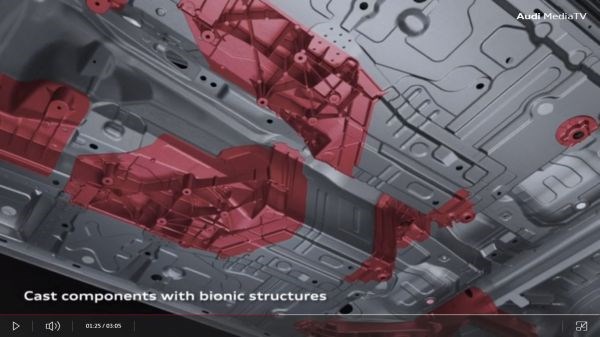

Now I’m seeing bionic structures expanding in automotive applications. In an article by Autocar.co.uk, the 2017 Audi A8 features an updated spaceframe body made from steel, magnesium, aluminum and carbon fiber reinforced plastic (CFRP). CW has walked through the CFRP rear wall in detail but look at the aluminum casting above. Audi has developed a technique that enables “natural forms like the lattice structure of a leaf or bird’s wing”. The result? Autocar reports stronger and lighter parts:

3. Thin-wall castings lighter and stronger than before

Audi says “Aluminum DNA is at the core of every Audi Space Frame” and with that in mind has developed a new technique to make the walls of aluminum castings thinner and stronger. The surface of components made this way resemble natural forms like the lattice structure of a leaf or bird’s wing to provide rigidity. Components are 50% stronger but the wall thickness is reduced by 15% resulting in a weight reduction of 19%. The two largest castings are 1.43m in length and connect either side of the passenger compartment to the boot.

SOURCE: Audi AG (click on animation at very bottom of the linked page)

Audi has expanded use of these cast metal “bionic structures” all along the underbody. Interesting that the rear wall and underbody are also major contributors to noise, and for electric powertrains, the underbody is used to support, protect and cool batteries. These are opportunities for composites to provide vibration reduction, sensing and other functions.

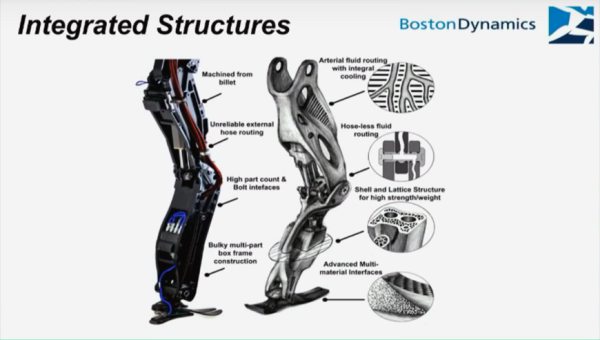

“3D Printed Legs are Next for Boston Dynamics’ Robots”

SOURCE: Rapidreadytech.com and Boston Dynamics

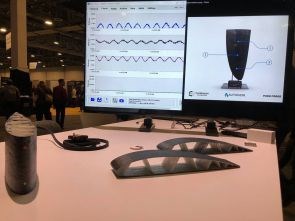

The range of applications for bionic structures is vast. I blogged on “Composites in exoskeletons” (or lack thereof) in 2016. The slide above shows where Boston Dynamics is headed. Now, imagine if this leg was 3D printed with continuous fiber composites (polymer or metal matrix) — not only lightweight and strong, but completely sensing.

The rudder below is a first step — 3D printed with chopped carbon fiber/ABS shell, continuous fiber frames and fiber optic sensors, allowing it to detect and report changes in temperature, pressure and electrical conductivity. And I mentioned metal matrix composites. Check out Jeff Sloan’s podcast with Greg Mark at Markforged, at about 28:20

“Where this goes is we do metal matrix composites. … Just like our plastic printer, you have to have a plastic printhead and a composite printhead. … On the metal printer, we’re just doing it in two steps. We’re doing a first step of just a pure metal printer and then the second step is a metal matrix printer.”) We’re obviously just at the beginning of what will be possible.

|

|

|

SOURCE: Continuous Composites and Autodesk, CW Blog “3D printing composites with continuous fiber”

This rudder brings us full circle to Autodesk and its support of multifunctional composite structures using generative design. But I found just a few more visual links in the chain.

3D printed metal obviously offers potential for actualizing bionic lightweight design, but stops short of fully sensing, multifunctional structures. Composites, however, offer nearly unlimited potential.

|

SOURCE: (left) “Filigree nature as a model for aircraft construction” by DW.com (image 5 in slide show) and (right) “Airbus unveils Thor, a 3D printed 4-meter long unmanned aerial vehicle, at ILA 2016” at 3ders.org (scroll to bottom of blog post)

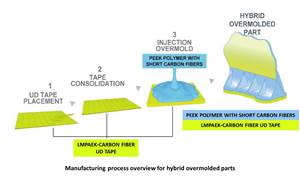

Note that composites could achieve similar structures using lightweight continuous fiber-reinforced blanks with overmolded ribs or 3D printed ribs.

Overmolded composites by CCP Gransden (left) and materials supplied by SGL (right).

Though composites have great potential to exploit generative design and bionic structures, as well as continuous fiber 3D printing and other 3D fiber deposition technologies, how the composites industry will address competition from 3D printed metals remains to be seen.

SOURCE: “Sogeclair Believes 3D Printed Casting Patterns are the Key to the Airplane Door of the Future” at 3dprint.com and Optimdoor at Voxeljet.com

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read MoreKraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More