Covestro is working on housing for refugees in Germany

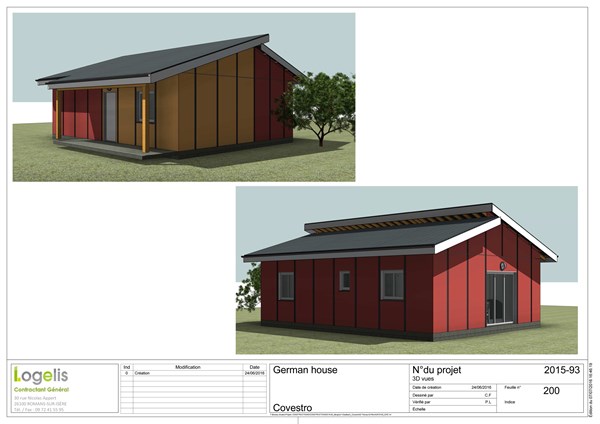

The model house in Bergisch Gladbach, Germany is made of self-supporting prefabricated elements with Covestro’s polyurethane core.

Covestro (Leverkusen, Germany) is teaming up with a French prefabricated home manufacturer Logelis to develop energy-efficient housing that can be erected quickly and inexpensively with flexible interior designs. The two companies have partnered with the town of Bergisch-Gladbach near Cologne, Germany on this project.

The partners have agreed on the first step: to build a model house. Bergisch Gladbach's Mayor, Lutz Urbach, Renaud Sassi from Logelis and Richard Northcote from Covestro recently signed an agreement to this effect in Bergisch Gladbach.

“The influx of refugees is presenting our towns and communities with ever bigger challenges. In Bergisch Gladbach, we see the collaboration with Covestro and Logelis as a possibility to accommodate asylum-seekers quickly and also humanely for a longer period of time,” says Urbach. Northcote, Chief Sustainability Officer at Covestro, says, “The project is a pilot model. If it proves successful, it would be easy to apply it to other towns and communities in Germany and elsewhere.” Sassi, President of Logelis, says, “Our company was established four years ago, and its mission is to provide housing at an economical price.”

The model house in Bergisch Gladbach will be erected on the site of the container settlement behind the integrated comprehensive school in the district of Paffrath and will be used as a multi-function building. It is made of self-supporting prefabricated elements from Logelis with a polyurethane core. Although the elements have a relatively low overall wall thickness, they still fulfill the requirements of the German Energy Conservation ordinance (EnEV).

The elements can be varied in shape and size according to the wishes of the client, which enables a wide variety of different designs, ranging from simple box shapes to multi-story units.

While considered a pilot project in Germany, it is not entirely new for Covestro, formerly Bayer MaterialScience. For several years now, the company has been supporting its industry partners in the Asia-Pacific region in projects involving the turnkey construction of cost-efficient housing units. The aim is to provide affordable, permanent living space to members of the underserved community, often in the aftermath of natural disasters.

“It has taken a lot of time to build the models, as well as the trust of the public sector and civil society,” says Northcote, “but we believe we are in a strong position to contribute more in our commitment to the United Nations’ Sustainable Development Goals. It is precisely this win-win situation that has met with such interest in various countries on the Indian sub-continent and in Southeast Asia and put us on track for success.”

Covestro is currently planning similar activities in the Middle East and Africa. The challenge everywhere is to persuade local companies to become partners in order to drive the projects forward with their respective areas of expertise.

This is how the model house of the town of Bergisch Gladbach and the companies Covestro and Logelis will look like. Photo credit: Covestro.

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.