Cutting Infusion Time And Cost

When open molders turn to infusion, careful planning, material selection and training precede process efficiency.

Consultant Andre Cocquyt estimates that, in the past year, about 700 U.S. composites manufacturers initiated a changeover to some form of resin infusion. Yet the results, he says, are often disappointing because the move can be made with a minimum of process modification. Boatbuilders, for example, can transition to vacuum infusion simply by widening the flange on existing open molds and adding vacuum bagging, resin transport lines and a vacuum pump. While this minimalist approach cuts worker exposure to and plant emission of hazardous air pollutants (HAPs) and other volatile organic compounds (VOCs), it may do nothing to increase process efficiency. In fact, Cocquyt (GRPguru.com, Stuart, Fla.) notes that for one client, the changeover initially resulted in a net increase in cycle time, from five hours to seven hours per hull.

How do we make it faster? "We hear that question about every day," reports Keith Bumgarner, technical service rep for resin manufacturer Ashland Specialty Chemical - Composite Polymers Div. (Columbus, Ohio). Answers to that question abound, in part, because the number of composites manufacturers who employ infusion has reached the "critical mass" necessary to make supplier development of infusion-friendly products profitable.

"The big players are really paying attention," Cocquyt says. Major distributors, such as Composites One (Arlington Heights, Ill.) and Ashland Distribution (Columbus, Ohio) offer comprehensive services and a wide range of time- and cost-saving materials, equipment and supplies to those making the switch to infusion. "As markets have changed and our customers face greater performance requirements to remain competitive … we have worked to offer a total solution to our infusion customers," says Mike Wallenhorst, global marine market manager for composite polymers at Ashland, where customers can work with experts in dedicated labs, developing an infusion process for their operations without taking time away from the production at their facilities.

"We learn their chemistries, laminate schedules, dimensions of the application and then return to our labs and start infusing small parts and panels to hone in on optimal physical properties and process parameters," says Troy Wade, Ashland's tech service manager for composites.

"They need to be prepared to re-evaluate the entire operation," adds Russell Elkin, tech services engineer at core supplier Alcan Baltek (Northvale, N.J.). "Looking at the secondary lamination operations — tabbing, bonding, reinforcing ribs, hardware attachment points and incorporating these into a single lamination process — these are the steps that make it truly 'closed molding' and not just 'laminating under a bag.'"

This comprehensive approach demands "a huge customer commitment," Bumgarner notes. But the payoff also can be huge, Cocquyt claims, noting that his previously mentioned client did so and now enjoys a cycle time of only 90 minutes.

BEGIN AT THE BEGINNING

To optimize infusion performance, the fabricator must first select the most practical method. 'Resin infusion' describes a fairly wide range of closed molding methods. To be categorized as infusion, a molding process must enclose dry reinforcement via bagging or a matched mold, followed by injection of liquid resin into the reinforcement. Today, that description fits a number of processes — 23 in all — including developer-enhanced variations denoted by acronyms like SCRIMP and SQRTM.

For discussion's sake, however, infusion methods may be classified in three major categories: The first, under the general heading of vacuum infusion processing (VIP), includes methods that use negative pressure (i.e., vacuum) to draw the resin through the reinforcement. VIP molds can be closed relatively inexpensively, using disposable vacuum bagging film on the previously open or "B" side of the part.

The second category includes all varieties of resin transfer molding (RTM), where positive pressure is used to push resin into the reinforcement. Methods that employ only positive pressure require a more expensive matched mold, with hard B-side tooling, to resist what can be very high injection pressures.

The third category covers any method that employs both vacuum and positive pressure, including vacuum-assisted resin transfer molding (VARTM) and light RTM. These methods may require hard B-side tooling as well, but depending on the balance of positive and negative pressure, the B-side may be formed from lighter, thinner and, therefore, less expensive materials. In some cases, reusable silicone bagging materials may be sufficient to support very light positive pressure.

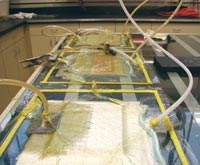

Cocquyt estimates that, overall, RTM is three to four times faster than VIP, using the same resin and reinforcement. Each type of B-side equipment also is characterized by different ranges of infusion rates. Composites One frequently compares light RTM, VIP (with nylon bagging) and closed-cavity bag molding (CCBM, with silicone bagging) at its infusion seminars. "Working with one resin system and the same reinforcements for all three," recounts Cocquyt, who works with Composites One on the demonstrations, "We show that, depending on how one manipulates the pressures, infusion speed varies significantly." CCBM, with some positive resin injection pressure, reportedly enables a pre-measured quantity of resin to be injected in a short period of time, typically less than a minute. As the injected resin flows through the laminate, fully impregnating the reinforcements, the operator can continue on to the next part. This results in significant time savings, since one operator can handle multiple parts, but it also requires a structural change in shop-layout. CCBM is most suitable for medium-volume production with minimal cosmetic requirements for the B-side of the part.

TOOL COST vs. METHOD SPEED

The cost of a hard B-side tool, estimated to start at $300/ft2 (USD), is relatively easy to justify for large quantities of small parts, since the one-time tool cost may be amortized over the the production run. Hard B-side tooling also supports the fastest cycle times. A small part, for example, can be enclosed in matched molds in less than a minute, while silicone bagging might take several minutes and nylon bagging might take 15 minutes to an hour or more for larger parts. Cocquyt contends, however, that for larger components such as boat hulls and decks, hard B-side tooling can be cost-effective only when production quantities reach three to four units daily, since the cost differential between hard molds and vacuum bags increases with the size of the component. In all cases, a net or very near-net shaped part can be produced, with finished surfaces on all sides, greatly reducing the time required for trimming and finishing operations. However, Composites One tech support manager Jim Gordon sets an upper limit on the largest part dimension at about 9m/30 ft. "For larger parts, vacuum infusion with nylon bagging is the only way you can go," he says. Even for smaller parts, nylon bags costing about $1/ft2, a cost that recurs with every infusion, are often the most cost-efficient option for short production runs, while reusable silicone bags, at about $40/ft2 and requiring replacement after a few hundred infusions, make economic sense only for larger runs. While the need for good B-side cosmetics may mandate hard tooling, Cocquyt says caul plates will suffice when only a portion of the B-side requires a finished surface. For example, a small boat with fore and aft decking may expose only a small area of the hull's inner surface. A caul plate can be used to produce a nonskid pattern on the exposed area. reducing post-mold work.

FUNDAMENTALS & FLOOR PLANS

While method selection is critical, no changeover should begin until the manufacturer has considered a number of areas where time and cost efficiencies can positively impact the process bottom line and the molder's competitive position.

Cocquyt encourages clients to start with the layout of the facility's manufacturing floor, where parallel manufacturing of components can save both space and time. "In boatbuilding plants, about 60 to 70 percent of the floor is used to store molds," he points out, noting that the same space could be used for parallel production stations, putting more molds to use at the same time. Instead of moving materials and equipment to stationary molds, he suggests moving molds from station to station, similar to automotive production, noting that one client, who once employed a crew of six to produce 17 parts per shift, today uses a "carousel" arrangement in which molds travel from station to station, producing 24 parts per shift with a crew of only three.

Small parts also can be made on time and on demand, a change from the common practice of producing at one time and then storing all the hatches, for example, needed for the year's production run. "Small-part fabrication often makes the worst use of real estate and labor," Cocquyt says.

For larger components in light RTM operations, the time it takes to apply gel coat and lay up reinforcements and core can be redeemed by acquiring multiple A-side molds. "A company might have three A-side molds — one being gel coated, one being laid up, and one being injected — with one B-side mold able to service all three A-side molds," Cocquyt explains.

Fabricators also assess their equipment needs, suggests Eddie Lane, Owens Corning's (Toledo, Ohio) product engineer for closed molding. A complete vacuum, for example, is essential to infusion efficiency, he says. Leaks that could be tolerated in open molding processes must be repaired. "People think you're pulling resin into the part with the vacuum pump," he clarifies, "but with no leaks, you could pull the vacuum, shut off the pump, and infuse the entire part. You want the mindset that there's no room for any leaks in the process."

To simplify vacuum sealing, ACTR (Provo, Utah) developed 3X Tooling, a spray-on polyurethane coating for the backside of composite or metal tools that seals microcracks and ensures vacuum integrity. The company also offers VACUSPRAY, a water-based product with glass microspheres, a spray-on vacuum bag material that can be reused.

KITTING AND COMBINING

One of the greatest contributions to process efficiency can be provided by suppliers. "The magic word is kitting," says Cocquyt. "You want to get scissors away from the floor," he quips. Kitting,

in which materials are precut and stacked to customer specifications to reduce lay-down time, can be performed with reinforcements, cores and vacuum bagging materials.

Suppliers and distributors such as Composites One, through its Kit Concepts program, offer reinforcement kitting services. But fabricators also can do a straightforward cost analysis to determine whether in-house kitting, which includes an investment in automated cutting and labeling equipment as well as software, is a good investment. One customer of GRPguru.com, for example, paid back the kitting investment in just 10 months, and that just from reduced scrap.

A prerequisite to kitting is redesigning the ply schedule for closed molding. "You have to rethink the laminate for kitting to make sense," Cocquyt says, noting that reverse engineering can be used on the open-mold design to determine key performance parameters. Closed mold laminate schedules then can be created to yield the same results. The higher fiber-volume fraction that results from closed molding often is undesirable, since it may negatively affect performance parameters such as impact resistance.

"Trying to maintain what the fabricator had in open molding requires going with loftier materials," Cocquyt points out. Accordingly, material suppliers now build in loft. At spheretex America Inc. (Ponte Vedra Beach, Fla.), for example, thermoplastic microspheres are used to increase the volume of reinforcements that can serve as core and/or laminate plies. Special infusion versions of the company's sphere.ax volumized multiaxial plies, sphere.mat volumized chopped strand mat, and sphere.core SBC precompressed and volumized mat have been tailored to closed molding pressure and resin-flow characteristics.Core manufacturers provide kitting services that include assistance in determining how to make the best use of core products in the laminate design. Alcan Baltek, for example, offers core material kits under its KITKORE brand. One kitting advantage, says national accounts manager Doug Hubbard, is that companies like his can provide hybrid kits, combining in one kit products such as BALTEK balsa, AIREX C70 PVC (polyvinyl chloride) foam, and AIREX T90/T91 PET (polyethylene terephthalate) closed-cell structural foam in densities ranging from 6 lb/ft2 to 25 lb/ft2. By varying material density, he points out for example that core thickness can remain consistent and needs no tapering when laminate is built up around a cutout. Steady core thickness greatly simplifies and, therefore, speeds lamination, Hubbard maintains.

To reclaim time in vacuum bagging operations, suppliers also kit bagging films with other disposable infusion aids. Richmond Aircraft Products Inc. (Norwalk, Calif.) has developed techniques for laminating multiple materials, including release film, breathers and bag films, into one assembly. The fabricator simply unrolls the kit onto the layup and applies sealant tape. Vacuum bagging system manufacturers also offer wide-width materials, such as Richmond's Vac Pak 400Y, available in widths up to 12m (472 inches), which significantly reduce joining operations on large components.

Fibertex Nonwovens (Aalborg, Denmark) offers CompoFlex as a replacement for release film and breather ply in vacuum bag processing. Developed in conjunction with wind blade producers Vestas and Siemens, the product combines peel ply, release film, breather and bleeder into one easily managed consumable, says the company. Its softer, microporous surface is designed to permit peel at one-fifth the force needed to remove standard peel ply.

VACUOPEEL, new from Diatex (St.-Genis-Laval, France) also is a multilayer system (without adhesive) that combines peel ply, perforated film, breather felt and bagging film. The material simplifies applications on vertical mold surfaces, eliminates flaws or loss of porosity caused by overlapping or missing materials and permits the user to remove the breather and perforated film, but temporarily leave the peel ply in place to protect the cured surface.

PROMOTING RESIN FLOW

Resin manufacturers, today, offer resins already optimized for infusion. But Ashland's Bumgarner points out that there's a limit to the process efficiency that can be gained in resin formulation alone, where flow speed is increased primarily by reducing viscosity. Resin formulators must be attentive to a resin's profile — the interrelationship between viscosity, out time, gel time and exotherm rate — for each infusion application. Infusion speed must be balanced against the reactivity and kinetics of the resin. An overthinned resin will infuse quickly, but the excess styrene can adversely affect the fiber sizing and the resin-fiber interface (see "Sizing up Fiber Sizings," CT April 2006, p. 18). "You don't want to infuse too quickly and create problems … when resin is sitting in the mold not curing," Wade explains. Attempts to balance the low viscosity by shortening gel time have their limits as well. "With too fast a gel time, the exotherm can cause surface problems," he explains. Consequently, the more significant gains in productivity can be achieved by promoting resin flow elsewhere in the process.

Reinforcement suppliers are designing product lines that help maximize resin flow. The VectorFusion line from Vectorply Corp. (Phenix City, Ala.) adapts the company's multiaxis, noncrimp fabric technology to create fiber geometries that provide channels for resin to flow and gases to escape. Likewise, Saint-Gobain Technical Fabrics' (Brunswick, Maine) new MAXFLOW multiaxial is laced with trace amounts of flow-promoting fibers that enhance resin flow and wetout. The company reports infusion rates double that produced in standard multiaxial reinforcements.

In solid laminates, a conversion from chopped-strand mat (CSM) to continuous-fiber mat (CFM) contributes efficiently both to final thickness of the laminate and to resin flow, says Owens Corning's Lane. During infusion, reinforcements are compressed prior to wetout, by about 30 percent as a rule of thumb, he notes. CFM is more resistant to compression and acts as a flow carrier. Chopped-strand mat also lacks continuous pathways for resin travel, Lane explains. Because CSM has been such a staple for boatbuilders, Bumgarner points out that it sometimes takes some convincing to prompt a change. "We have infused two panels side by side for some customers to show them how differently the flow fronts advance."

Woven fabrics, a staple of open molding, must be handled differently in infusion operations, Lane continues. "If you simply stack woven roving, it will tightly nest and not allow resin flow," he explains, "but with interlayers of continuous filament mat, resin flow is enabled." Owens Corning offers FlowRo, a 814 g/m2 (24 oz/yd2) woven roving with 67.8 g/m2 (2 oz/yd2) CFM stitched to it, for a total areal weight of 881.8 g/m2 (26 oz/yd2). The patent-pending construction results in unsurpassed resin permeability, the company claims, and it keeps ply count down by quickly building laminate bulk with an infused thickness of 0.065 inch/1.65 mm per layer.

Owens Corning also offers FlowTex, in which CFM layers are stitched to unidirectional plies of glass, like traditional stitched multiaxials. Initial tests of FlowTex 2820, a biaxial knit with CFM, demonstrated a 40 percent increase in resin flow rate as compared to traditional biaxial knits with CSM, the company reports. The product incorporates flow channels in its patent-pending structure, a configuration that also increases loft and decreases weight, Lane notes. He estimates the glass weight of a 0.25 inch/6.35 mm laminate produced by using six plies of a 1120 g/m2 (33 oz/yd2) glass fabric at approximately 1.43 lb/ft2. In a similar laminate made from four plies of 2820, the glass weight falls to about 1.2 lb/ft2, demonstrating that the substitution of CFM for CSM can increase the thickness per ply, reduce the weight of the finished laminate and reduce the labor required to produce it.

Core manufacturers not only develop core kits, but, to facilitate resin infusion, also can score and/or perforate balsa or foam to enhance resin flow. Alcan Baltek pioneered "GPS" (grooved, perforated, slit) core materials, says Hubbard, as a means to minimize resin uptake and air entrapment in the core during the infusion process.

A number of suppliers provide a unique group of materials called flow media. When placed strategically in the layup, flow media help distribute resin throughout the part, to avoid dry or resin starved areas. Flow media differ significantly. Some are designed to be removable while others remain in the laminate, often playing an additional role.

An example of the latter is the SORIC line from Lantor Composites (Veenendaal, The Netherlands), which functions as both flow medium and core. Distributed in the U.S. exclusively by Alcan Baltek, the product is similar to bulker mat used in open molding. It consists of a lofty layer of synthetic fibers embedded with microspheres in a special noncompressible foam matrix, which, according to Lantor, loses less then 10 percent of its thickness under full vacuum. While it builds laminate thickness as a saturated core, SORIC's outer layer of synthetic fiber features honeycomb-patterned channels on its surface, which enhance flow along the outside of the product. "This pattern allows rapid infusion of resin, with an even flow front," says Lantor sales manager Marc Veldstra. Three types address different needs: SORIC SF is the general-purpose product with relatively small cells; SORIC XF possesses larger cells for maximum flow and greater thickness (up to 6 mm/0.25 inch); and SORIC TF, with the smallest cell size, is designed to aid cosmetics. In combination with Lantor Finishmat D7760, a polyacrylic nonwoven veil, Veldstra maintains SORIC TF may be able to eliminate "skin" coats, such as the barrier coatings that are applied between gel coat and the reinforcement layers to prevent print-through, with no negative effect on gel coat surface appearance.

EnkaFusion distribution media from Colbond Inc. (Enka, N.C.) "has as its basis a unique configuration of random monofilaments that are fused together to form a very open, unencumbered structure," explains Thomas Robrecht, Colbond's industrial products manager. While the structure builds laminate thickness, its major function is to create a space for resin flow where none existed before, Robrecht notes. (EnkaFusion products also can be used as disposable layers on the outside of the reinforcement, strictly for flow enhancement.) "The dimensionality and randomness of the filaments help to completely wet out the fiberglass," he maintains.

Colbond's EnkaFusion Type CX-1000 flow medium replaces spiral wrap commonly used as the major resin feed line in infusion processes. Spiral wrap is a coiled plastic ribbon that permits resin to travel quickly down the length of its interior but also permits resin to pass through its walls into the adjacent layup. CX-1000 consists of a 10-cm/4-inch polyester V-groove core encapsulated within a polyester fabric. The V-shaped channels allow resin to travel quickly through the medium and seep out through the jacket. In many cases, CX-1000 simply remains in the cured part.

Chomarat Composites' (Richdale, U.K.) Rovicore, a reinforcement made from a synthetic nonwoven core of large fibers sandwiched between chopped glass mats, is mechanically stitched together (no binder), producing a conformable, flexible and compressible reinforcement for RTM or vacuum infusion. The company's Roviflow reinforcement form features an integrated resin transport medium, eliminating waste and saving labor in VIP.

Similarly, Nida-Fusion STO closed-cell foam core material, from Nida-Core Corp. (Port St. Lucie, Fla.), is covered with reinforcing fiber layers, helping to speed layup as well as infusion time. A network of fiberglass "bridging" strands links the cover layers to the core. Another product, NidaFlow, includes a conformable needled nonwoven polypropylene core designed for good resin flow, stitch-bonded between two layers of chopped glass fiber. It's compatible with many resins, including polyester, vinyl ester, epoxy and polyurethane.

Among the newest media are Polynova Composites' (Milford, Mass.) HIFLUX 90 infusion flow reinforcements. Engineered to be part of the laminate, the high-tenacity polyester medium is available in widths from 152 cm to 406 cm (60 inches to160 inches). The company reports that the material improves impregnation rate and uniformity during infusion and contributes to laminate properties after cure, while reducing waste associated with disposable flow media.

ELUSIVE WITHOUT EDUCATION

Suppliers of infusion products universally caution that, while the foregoing are important, thorough training is essential. Here suppliers stand ready to help as well. "We often bring the customer into the lab to train offline and avoid interrupting their production," says Ashland's Wade, noting that his company's experts return with trainees to their shops for live trials, which also permit them to tweak both process and chemistry.

"A well-trained staff," says Composites One's Gordon, "is key to the consistencies that create fast cycle times."

Related Content

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)