Design Issues With Tendons

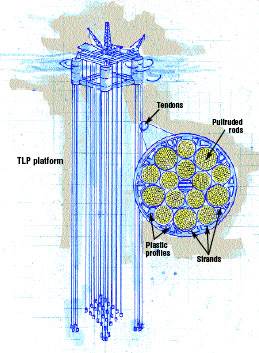

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/5

Share

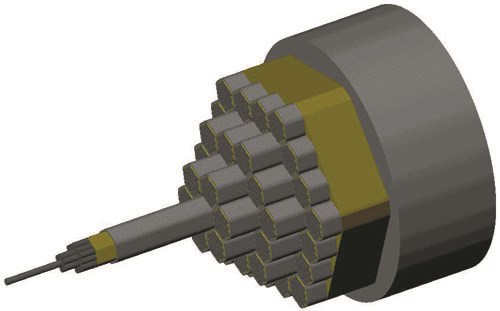

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/50 to 75 mm in diameter, are bundled together to form a single tendon. The tendon is jacketed with a thermoplastic material for in-service protection, then spooled onto a reel for transport. Composite tendons can be pultruded and cabled in continuous lengths, eliminating the need for intermediate joints, although in deeper waters, it may still be necessary to join multiple sections.

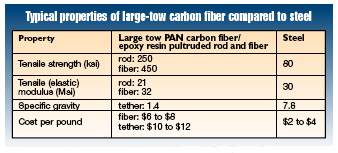

According to Mamdouh Salama, a senior research fellow at Conoco Inc. (Ponca City, Okla., U.S.A.), the high stiffness-to-weight ratio for carbon fiber composites is the key to their utility.

“The tether design is stiffness-driven, so a tendon with the required stiffness actually provides more tensile strength than we need — a benefit that reduces potential fatigue problems in the tether,” says Salama. “In addition, composites permit greater design flexibility for tailoring properties to meet the platform’s specific design requirements.”

Conoco and Kværner Oilfield Products ( KOP, Oslo, Norway) tested different types of carbon fiber composite tendons. Pultruded rods made with 48K, 50K and 80K intermediate-modulus polyacrylonitrile (PAN) carbon fiber and a customized epoxy resin were compared to rods made from a high-modulus 12K pitch carbon fiber in a vinyl ester matrix. The different types of rods performed comparably during tests for transverse strength, torsion and fatigue, although the high-modulus rods showed a greater elastic modulus in static tensile tests (50 percent greater than the intermediate-modulus rods).

The results indicated that large-tow carbon fiber, such as that supplied by Tenax Fibers (Wuppertal, Germany) or Zoltek Corp. (St. Louis, Mo., U.S.A.) is more than adequate to meet the performance objectives. The stiffer pitch carbon fiber produces a thinner tether that weighs less and produces less drag, but at a higher cost. Salama reports that Conoco is working on a reduced-cost high-modulus carbon fiber alternative, but doesn’t expect it to be available for several years.

The results of the Conoco/Kværner test make sense, says Zsolt Rumy of Zoltek. “The modulus or stiffness of commercial heavy-tow fibers is competitive with aerospace-grade fibers for these kinds of projects,” he explains. While heavy tow delivers somewhat less strength, what it lacks is not necessary for the application. Therefore, Rumy concludes, “They perform as well and the cost over the long run will be much less.”

Because composite tendons are inherently corrosion resistant and have few joints that require inspection, maintenance goes down and reliability goes up. In addition, optical fibers can be embedded in the carbon fiber rods to monitor tendon strain during testing and actual operation. Rod or strand failure can be detected electronically by local or remote operators, and receive immediate attention. Optical sensor technology has been successfully demonstrated in performance testing on composite tethers, and is significantly less expensive than the complex and often unreliable conventional steel tether load cells.

CSO Aker Maritime (Houston, Texas, U.S.A.) considered a tubular design for composite tethers. This type of tendon would be neutrally buoyant, reducing required pretension and hull size. However, tubular tendons are not spoolable. Therefore, they must be manufactured and transported in shorter segments and joined at installation. The additional terminations required would add cost, increase maintenance and potentially increase reliability problems. A hybrid tendon concept, consisting of a lower rope segment and upper tubular segment, was not cost- or performance-competitive. A ropelike composite tendon is the currently preferred design.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Composite Tether Goes To Sea

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

Read More

.jpg;maxWidth=300;quality=90)