Alpex Technologies (Mils bei Hall, Austria) is a small-to-medium enterprise (SME) located near Innsbruck with 50-70 employees and more than 20 years of experience in the composites industry. The company has been a featured supplier and/or subject in at least seven CW articles, see topics below. I first saw their equipment during my tours of FACC (Ried im Innkreis, Austria), Benteler SGL (Ort im Innkreis, Austria) and Mubea Carbo Tech (Salzburg, Austria). Oddly, I didn’t list them as a supplier in any of those articles, probably because I was just learning about them and not yet fully aware of how much technology they have supplied into composites production. Alpex Technologies supplies many other leaders in composites including GKN Aerospace (Redditch, U.K.), Premium Aerotec (Augsburg, Germany) and Automoili Lamborghini (Sant’Agata Bolognese, Italy).

So, why blog about Alpex Technologies now? Because I’ve been watching their LinkedIn posts and noted their recent R&D projects on digitalization, biocomposites and thermoplastics. These are hot topics in composites and I wanted to see where they are headed.

Long history in composites

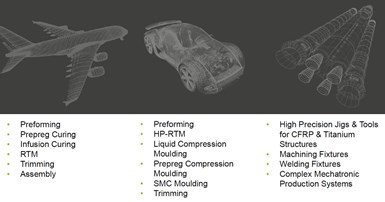

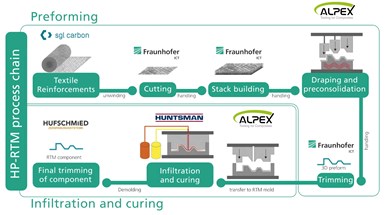

“We deliver tools from preforming to resin transfer molding [RTM] and resin infusion to trimming and assembly,” says Dr. David Kampenhuber, business development leader for Alpex Technologies. “For example, we supplied the preforming tool used by Voith Composites (Garching, Germany) in their system that produces over 300 preforms per day [see CW article on Audi A8 rear wall].” The company has also supplied tools for low-pressure and high-pressure RTM (HP-RTM) to BMW, as well as tools for SMC (sheet molding compound) and wet compression molding (WCM). “For our HP-RTM developments we often are partnering with KraussMaffei [KM], which supplies the metering and mixing equipment and acted as an industrialization partner for HP-RTM with BMW starting in 2011. So, from the automotive side, we know high-volume manufacturing and we look at how to transfer this knowledge to the aviation industry,” says Kampenhuber. “We can set up your process for manufacture of carbon fiber reinforced polymers (CFRP), but we don't do injection molding tools.”

“In aviation, we did a lot of work to help make the resin infused composite wing possible for the MS-21,” he continues. “We provided assembly jigs for manufacturing and for final assembly, as well as tools that were, I think, the first to cocure stringers to skin during resin infusion. So, our expertise is not just RTM or building massive blocks of tools for HP-RTM in automotive. Our spectrum is much wider. However, there is a lot of discussion now about such tooling for CFRP wheels and rims in automotive.”

Other areas of Alpex Technologies innovation and topics in CW articles include: steel/composite leaf springs, the SPARTA and TAKE OFF projects for 2-part epoxies and HP-RTM in aerostructures, Compression RTM, 3D-printed molds for an RTM flaperon and thermoplastic RTM.

Photo Credit: Alpex Technologies Feb 2022 LinkedIn post

“RTM molds can get really complex,” notes Kampenhuber, “for example, as soon as a component has undercuts, when it is not just a flat plane, you must apply techniques to ensure vacuum tightness and flow media tightness for resin infusion. But you must also be able to eject or release the part afterwards. This then requires a combination of fixed massive blocks to withstand high pressures and sliding elements that need to be sealed to each other. And from the automotive side, this is one of our areas of expertise.”

“We have also done this for GKN Aerospace,” he continues, “to achieve low pressure RTM over an 17-meter length where the components have an undercut. You have to eject the part but synchronize this, for example, so that you can remove the tooling inserts for the interface areas. But these also must be sealed during injection and cure. So, it’s necessary not only to precision machine the mold shape, but also to combine industrialized parts and components into a tooling system. And it is more than just combining the motorized bits with the precision shape because tooling for composites production is indeed a system. So, we must look at integrated functionalities but also how to make the design and operation simple. We look at how to optimize the whole process; we don’t just make tools for large, expensive presses.”

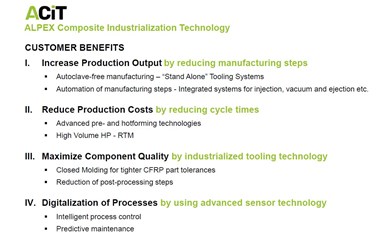

Alpex industrialization for composites

AciT stands for Alpex Composites Industrialization Technology. “It stands for what we try to offer to our customers,” explains Kampenhuber. “Often the challenge they face is to increase output and reduce costs, which means quality must increase, and this demands digitalization. And from the automotive HP-RTM and leaf spring projects to the more recent GKN spar projects, we see a trend towards stand-alone tooling with integrated heating, cooling and intelligence — including sensors and regulation/control of the systems. This all must be combined to increase the efficiency of the process.”

“And this demands understanding the interfaces within the whole process chain,” he continues. “For example, if you have no understanding what the preform requires or the subsequent process steps and how the part is finished, you won’t be able to realize an efficient, intelligent tool. For this, you must consider how the tool can be made efficient in terms of part handling, how does it move and eject/release parts, how can energy usage be reduced and how can extra steps be deleted? All of this is needed to increase efficiency and save money.”

“… the molding must be controlled based

on the information gathered in the

previous steps.”

“If you don't control your process very well, you really are in danger to scrap parts,” he warns. “How transparent is your process? In other words, how much can you see? What are the pressures and temperatures? How are the vacuum and injection systems reacting to each other? Take the GKN Aerospace 17-meter spar as an example, just the material is very expensive but if you also account for the time needed to make the preform, transport it to the tool, prepare the tool and finally mold the part — this adds up to quite an investment. If you do not have a digitalized process to see what’s happening all along this process chain, you are risking the part and all of that investment. Not only that, but the molding and following steps must be controlled based on the information gathered in the previous steps.”

Another part of ACiT is to offer customers the benefit of faster production via material innovations, such as the use of two-component resins in RTM. “More and more work is going toward certification of 2K resins for RTM in aviation,” says Kampenhuber, siting programs with leading aviation suppliers and many factories in Germany. “We see a benefit to our customers to offer integrated sensors and techniques within the tool to validate the mixing quality of these two components. We are working to provide mixing quality assurance so that parts manufacturers know that the quality of each part is good.” (Read “HP-RTM for serial production of cost-effective CFRP aerostructures” and “2-part epoxy for increased composite aerostructures production via RTM”.)

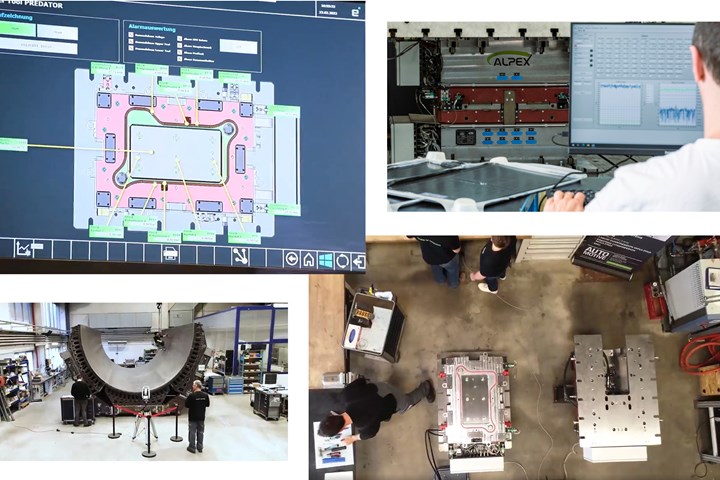

PREDATOR project

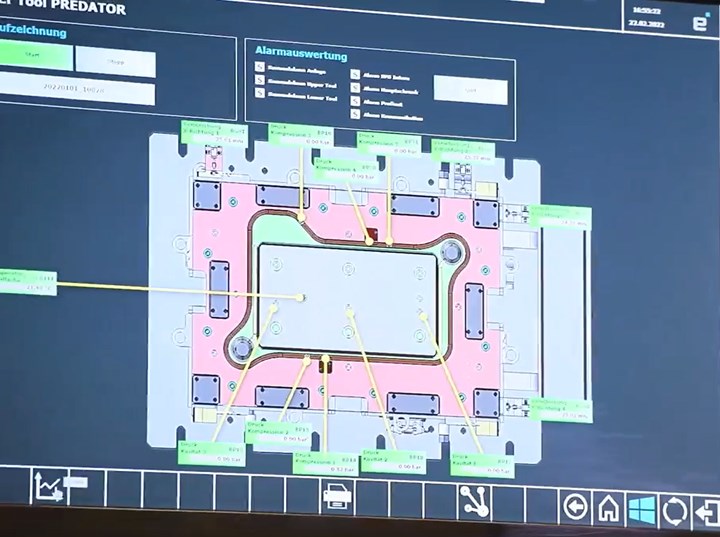

In PREDATOR, Alpex Technologies integrated 62 sensors in an HP-RTM tool used to make hundreds of CFRP plates to demonstrate digital part fingerprinting and QA. Photo Credit: Fraunhofer ICT

PREDATOR, which stands for “Predictive Maintenance and Data Based Optimization of Production Technology for Composites”, is a research project from 2020-2023, funded by Eurostar government agencies DLR in Germany and FFG in Austria. The goal is to exploit the high-quality and low cycle time of HP-RTM while improving its robustness by implementing a digitized data acquisition system. This system would automatically capture and transfer data along the process chain — in this case, from molding to post-processing — and use this data to monitor, control and provide quality assurance (QA) through each step.

A key demonstrator is to integrate sensors into the milling process to monitor the component’s structure-borne sound for tool wear and predict part quality. This data is used to optimize the milling process but also predict maintenance intervals for the HP-RTM mold. The project aims to show up to 30% reduction in total production cost by changing from 100% post-process inspection to a milling-process-integrated QA.

PREDATOR partners and contributions include:

- Smart HP-RTM production tool by Alpex Technologies with wear parts (like ejectors and sealings) monitored with sensors to offer improved maintenance services and increased reliability.

- Modular software solution by Boom Software (Oldenburg, Germany and Leibnitz, Austria) to process sensor information from different productions steps to be used as input values to optimize the milling process.

- Machining specialist Hufschmied (Bobingen, Germany) will provide a system to correlate structure-borne sound during composite component milling to the part quality and wear condition integrated QA system.

- Fraunhofer ICT (Pfinztal, Germany) will develop quality control techniques within the HP-RTM manufacturing chain to improve industrialization for serial production of composites.

“Within the project, the HP-RTM tool from Alpex is connected with the HP-RTM press and injection system,” says Kampenhuber. “We included 62 sensors in all — some for process monitoring and some for tool condition monitoring — and this enables digital fingerprinting of each part and its process details. We made between 300 and 400 CFRP plates, each with a digital fingerprint.” The idea for Hufschmied to use ultrasonic sensors to monitor defects during part finishing helps to reduce steps, says Kampenhuber. “Their correlation of this sensor data to part quality combines QA into part trimming and machining.”

Alpex is developing multi-sensor tools with a single Ethernet interface while enabling flexible data monitoring options. Photo Credit: Fraunhofer ICT

“In the end, there are multiple electronic devices on the PREDATOR tool,” notes Kampenhuber, “but Alpex tries to simplify the interface problem for the customer to as few standard connections as possible, such as an Ethernet cable. This avoids the situation where every sensor has a cable in every device and then you must devise modifications in order to communicate with your laptop or tablet. We want to avoid this while allowing our customers to define how they want to get the data. Maybe they want to have a color-coded dashboard or else prefer to export the data directly into an ERP system or into a PC- or tablet-based analysis program. The issue is not just how to achieve a data dump, but how to collect and use this process data to provide meaningful information for improving production.”

Next-gen tooling systems

Alpex Technologies continues to work on numerous R&D projects such as EMOTION (top) which includes an innovative, segmented tool design for high-temperature thermoplastic composites, and a 3D-printed tool for an RTM flaperon (bottom) in the Clean Sky 2 project COMBO3D.

“What we want to offer is the ability to send the data our customers need in away that is easy to use so they don't need to bother about how to transform the data,” notes Kampenhuber. “What we also offer is that in the middle of production — or even in part and process development — we are not just providing data, but knowledge. This is based on the data we can collect and on our experience tooling systems and composites production. That includes where tooling can deteriorate and what the crucial process aspects may be. We can either use that data and knowledge to set up an easy-to-use system or process operators — such as a green, yellow and red light dashboard — or we can set up the process to be adapted automatically — for example, to sense lack of pressure and respond with increased force in the press, to modify the temperature of the heating device because there are cold spots or to pull vacuum again because there is a loss of vacuum pressure.”

“This is where we are heading,” he continues, “and it is really a benefit to the customer to be able to modify the process as needed in situ instead of just seeing the problems afterward, during the QA check. We also want to offer correlation analysis to optimize the process and equipment. For example, we can check for deterioration in a tool’s heating or sealing, enabling the customer to act preemptively instead of waiting for a problem, and thus avoid unexpected maintenance costs and production interruptions.”

Kampenhuber believes these developments can be very beneficial, especially for aviation, where processes are not very transparent. “Process transparency has been better in automotive, because if a process stops, the cost impact is high. Aviation has not had this issue, but now production rates are increasing, and composites processes must also have this transparency — showing pressure, temperature and all the basic parameters — to avoid costly bottlenecks in production and also to gain process and part knowledge for optimization.”

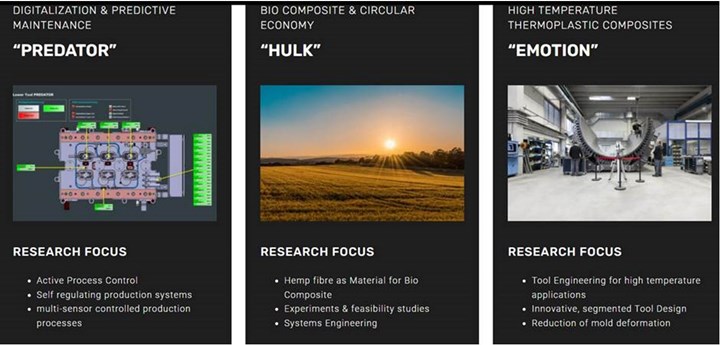

In 2021, Alpex Technologies established its next 5-year strategy, which comprises three major focus areas. “We want to steadily improve the industrialization of composites part manufacturing and to increasingly enable digitalization of this production,” says Kampenhuber. “We also want to play a pioneering role in the development of technologies for manufacturing of components using biocomposites. We regularly participate in funded R&D projects, but customers also come to us and say, ‘we have an idea of what we want to do, and we know your background in tooling systems, so how can we do this?’ So, we do a lot of work with the industry. In those cases, we work with our customer to refine the concept and engineering and maybe further develop the process, with respect to the interfaces and equipment setup, etc. And if the company wants to then award us with the contract to build the tooling, then fine. We also build to print. But even there, we try to provide information about where customers need to invest, based on our experience. As we set up processes and integrate our equipment into their facilities, we always try to show possible drawbacks and improvements.” This is who Alpex is, he says. “We take on a lot of challenges and try to solve problems across different materials, processes and market sectors. Our goal is to make composites production more efficient and sustainable.”

Related Content

NREL develops biomass-derived resin PECAN for wind blades

Demonstration and findings validate PECAN as a method for developing long blades that perform well with composites, outperform some resins and enable chemical recycling.

Read MoreBioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreBiomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreDITF develops water-spun lignin fibers as PAN precursor alternative

Lignin fibers produced via an aqueous solution and dry spinning process result in homogeneous, smooth-surfaced fibers that are more environmentally friendly and cost-saving.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)